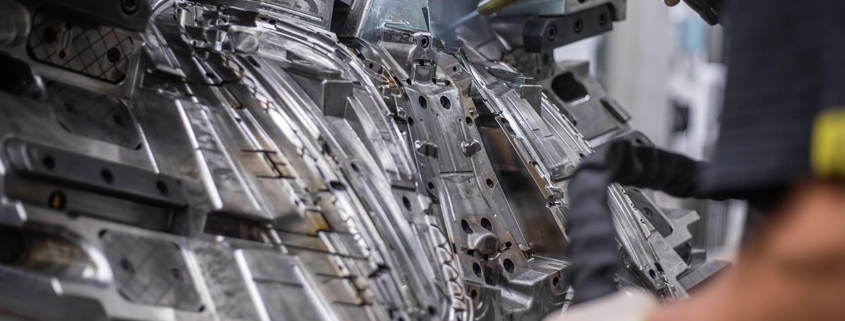

Auto checking fixture inspection tool is a professional measuring tool used for accurate measurement and inspection of cars. The main body of the gage includes the gage base, the body and the mounting part. The base and the body are usually made of epoxy resin or aluminum. In the product verification stage, automotive checking fixture can play a key role, especially in the first trial assembly stage of batch parts. Gage manufacturing is usually made of aluminum, resin or iron parts, taking into account daily maintenance and service life, it needs to be regularly maintained and treated. The main role of automotive inspection tools is to ensure the accuracy and quality of automotive parts in the automotive manufacturing process. The structure of the tester base and the vehicle body surface is stable and reliable, which can ensure the accuracy and precision of the measurement. Therefore, the automobile inspection tool is an indispensable and important tool in the automobile manufacturing.

The role of instrumentation in the automotive industry.

The automotive industry is one of the largest manufacturing industries in the world, and the gage plays a vital role in this industry. A gage is a device or tool used to measure and verify the size, shape, position, and function of a part. They are an important part of the manufacturing process, ensuring the quality and consistency of the product. In the process of automobile manufacturing, the gage is a key tool for quality control, and the importance of the gage in the automobile industry is self-evident. They play a vital role in quality control, ensuring that products meet design specifications and tolerances. At the same time, the variety of fixtures and their integration with automation equipment enable them to adapt to the changing manufacturing environment. As the technology evolves, we can expect that the check will play an even greater role in the automotive industry in the future.

Automotive checking fixture is a special equipment used to control and measure the size, position and shape of automotive parts in the automotive production process. These devices are essential to ensure the quality and accuracy of the vehicle. In this article, we will explore the design ideas of automotive inspection tools and how to optimize the design process to meet changing manufacturing requirements. Before the design of the auto tester, first of all to clarify its objectives and uses, in the design of the auto tester, the need for a detailed analysis of the structural characteristics of the auto parts, according to the structure and characteristics of the parts, select the appropriate measurement methods and tools.

About

Case

RD

FAQ

Product

Application

Support

Blog

Tel: 0752-2090655

Mail: sales@jztester.com

Add: Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou