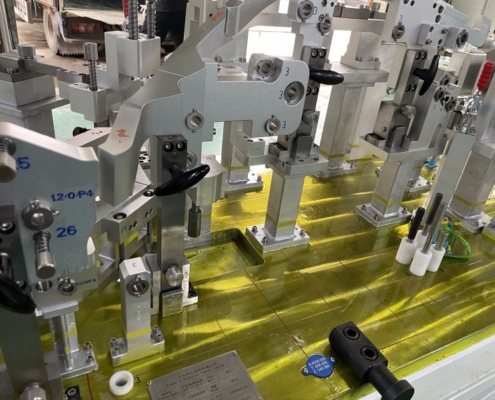

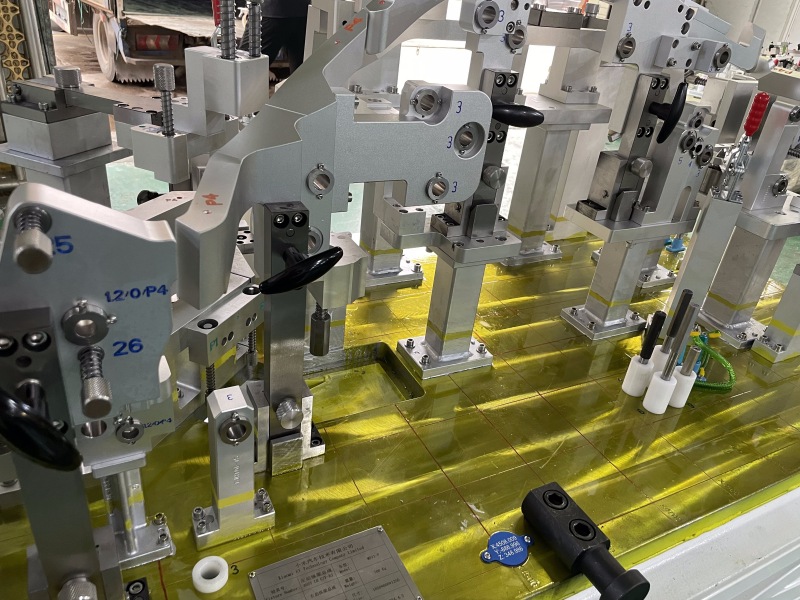

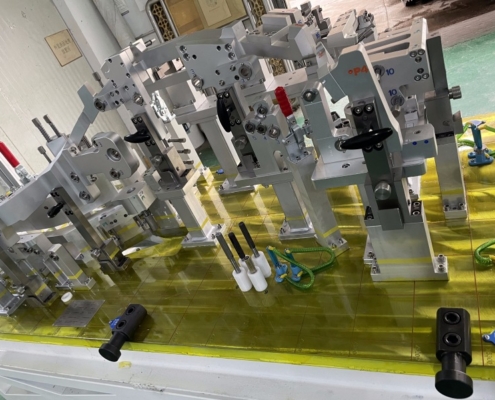

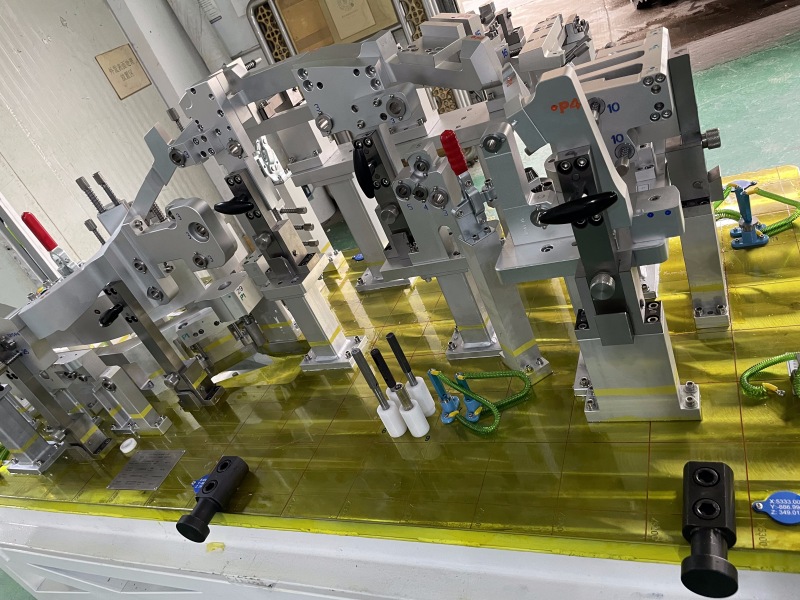

Our custom checking fixtures and inspection fixtures deliver precision dimensional, positional, and functional verification for automotive suppliers, mold makers, and precision component manufacturers. Engineered to your exact CAD/GD&T specifications

Test checking fixtures and gauges components manufacturers

Our car part test checking fixture can be categorized into three types based on the inspection object:

- Stamping Single-Part Checking Fixture

(For inspecting individual stamped components)

- Subassembly Checking Fixture

(For verifying assemblies composed of multiple parts)

- Modular Integrated Checking Fixture

(Designed for complex systems combining multiple subassemblies)

Key Features of Our Inspection Fixtures

Our Car Part Test Fixtures are built with precision and versatility in mind. Below are the key features that set our products apart:

- Customizable Design: Tailored to your specific car parts, including complex mold components, precision parts, and assembly components.

- High Accuracy: Advanced fixtures ensure micrometer-level precision for dimension, alignment, and functional checks.

- Durability: Made from premium materials, our fixtures are built to withstand wear and tear in demanding manufacturing environments.

- Easy Operation: Designed for efficient and user-friendly use, reducing setup time and improving workflow.

- Wide Application: Suitable for various industries, including mold manufacturing, automotive parts production, car assembly, and quality control.

Technical Specifications:

- Compliance: Pre-programmed for automotive industry standards.

Rapid Cycle Times: Reduces inspection time by 40% compared to manual methods. - Data Traceability: Generates PDF/CSV reports for audit trails and process optimization.

- Scalability: Upgrades available for emerging technologies (e.g., AI-driven defect prediction).

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Applications

- Mold Validation: Verify tooling accuracy before production runs.

- Post-Machining Checks: Ensure CNC-milled parts meet design specs.

- Assembly Line QC: Catch mismatches in welded/bolted components.

- Prototype Testing: Accelerate R&D cycles with reliable data feedback.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF