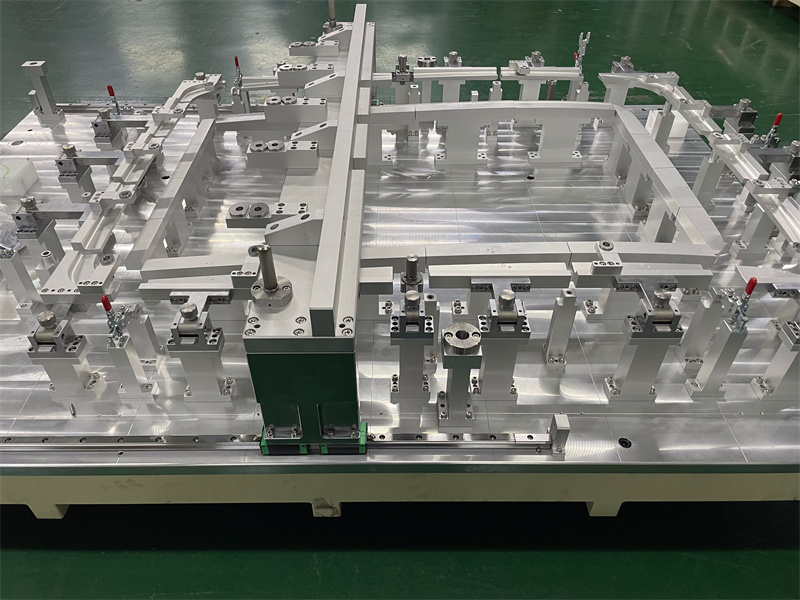

Our CMM Holding Fixtures are precision-engineered tools designed to securely hold and position automotive and mold components during Coordinate Measuring Machine (CMM) inspections. Engineered for high accuracy and durability, these fixtures help you measure critical dimensions, verify positional accuracy, and validate the functionality of complex parts

Precision CMM Holding Fixtures for Mold & Component Inspection

Our CMM holding Fixturing inspection Tools can be categorized into three types based on the inspection object:

- Stamping Single-Part Checking Fixture

(For inspecting individual stamped components) - Subassembly Checking Fixture

(For verifying assemblies composed of multiple parts) - Modular Integrated Checking Fixture

(Designed for complex systems combining multiple subassemblies)

Key Features:

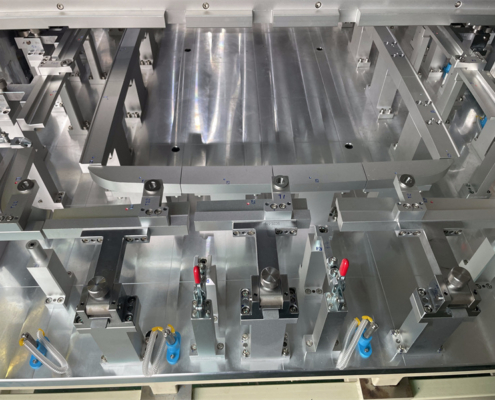

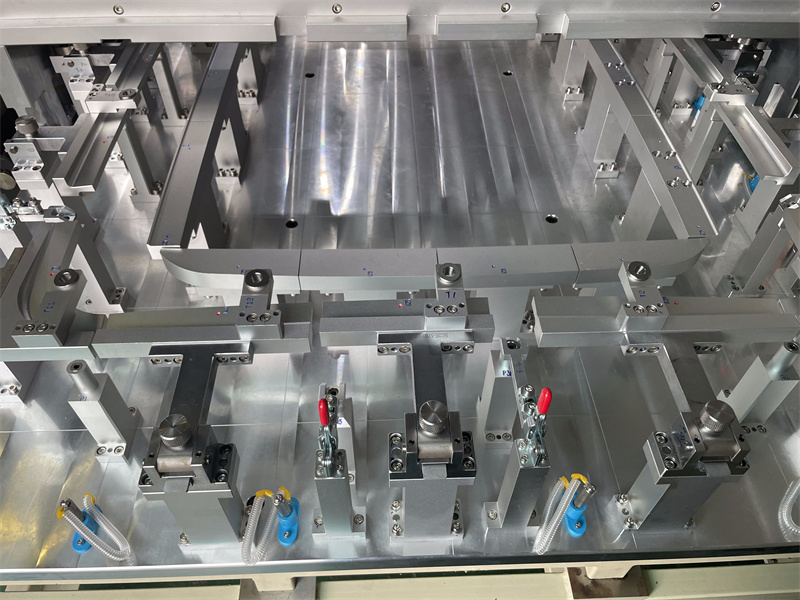

- Modular Design: Fixtures that can be reconfigured for different part geometries.

- Advanced Clamping Mechanisms: Zero-shift clamping to ensure consistent positioning.

- Customizable Supports: Adjustable arms and pads for uneven or complex surfaces.

- Easy-to-Use: Tool-free adjustments for quick setup and reconfiguration.

- Software Compatibility: Works seamlessly with CMM software like PolyWorks and Mastercam.

Technical Specifications:

- Processing Precision: Ensures high-level accuracy during the checking process.

- Accuracy for Other Profiles: Ideal for single stamping, assembly, and casting checking fixtures.

- Datum Hole Accuracy: +/- 0.05mm, ensuring precise measurements for critical dimensions.

- Material: Made from top-grade materials to ensure reliability and durability.

Applications for Mold & Precision Parts

1. Mold Component Inspection

- Core/cavity dimensional verification

- Ejection pin position alignment

- Cooling channel functional testing

2. Automotive Tooling Validation

- Fixture-gauge correlation (FGC) for stamping dies

- Functional checks of sensor mounting points

- Batch consistency testing for injection molds

3. Aerospace Component QA

- Turbine blade profile inspection

- Composite part warpage measurement

- Threaded hole position validation

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

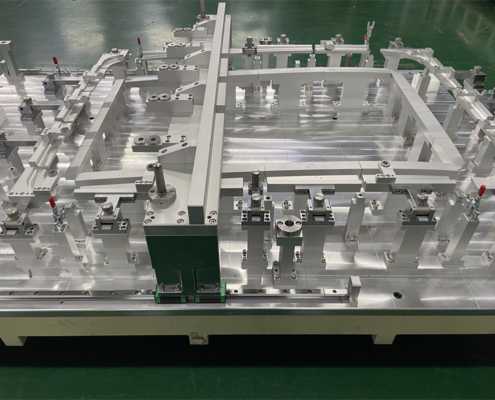

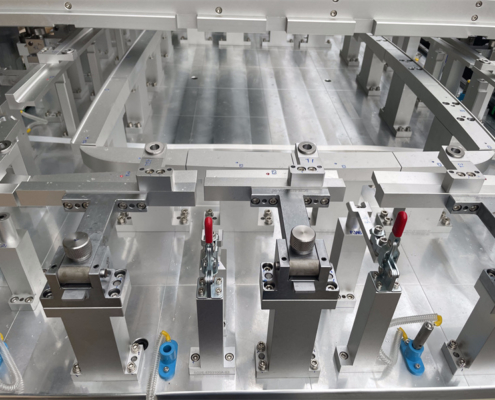

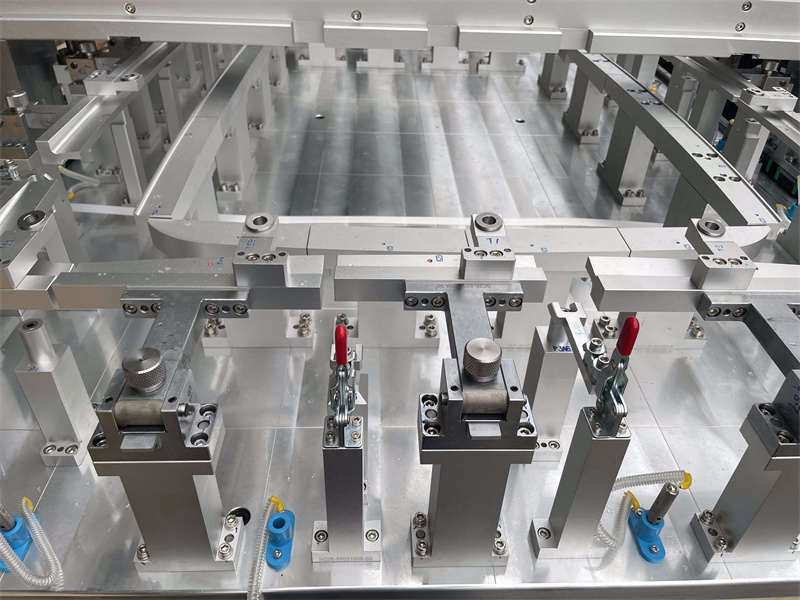

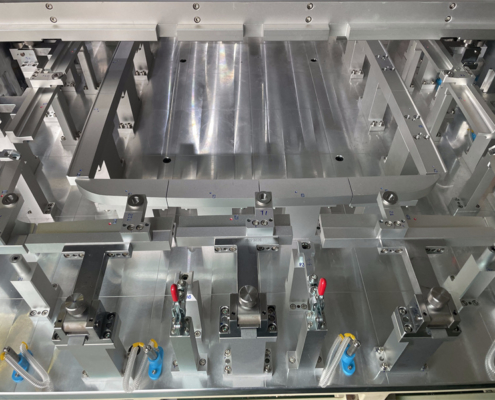

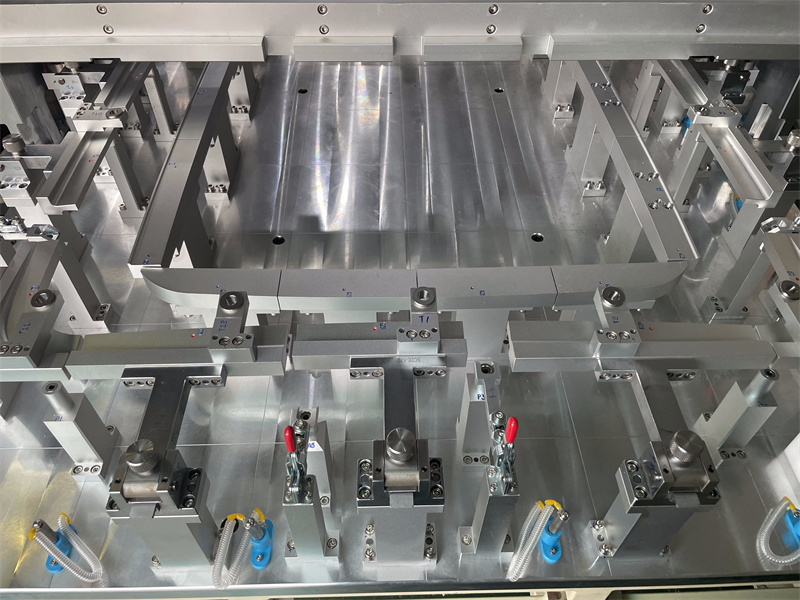

Assembly checking fixture for plastic panel of automotive

This assembly checking fixture set use cable retractors to control and clamp, and design the SPC ports as part of the flush/feeler rails as opposed to the simulation rail(s).

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF