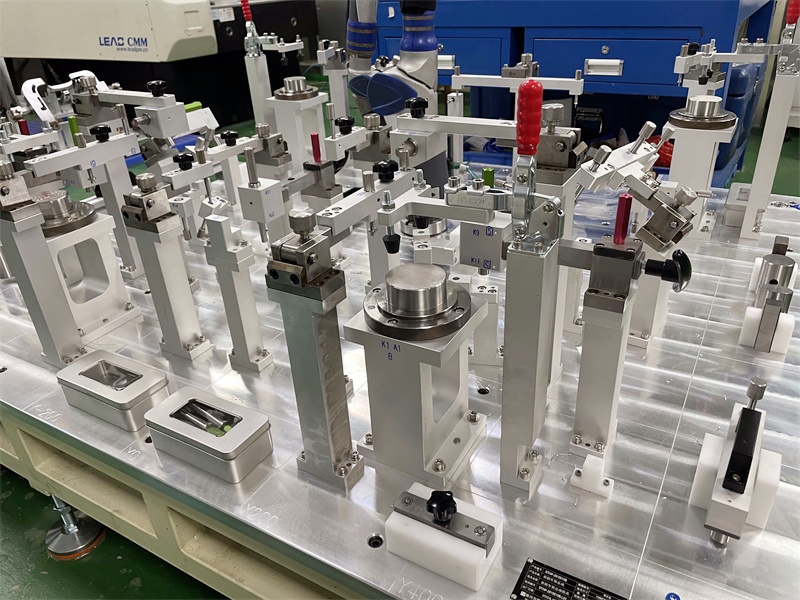

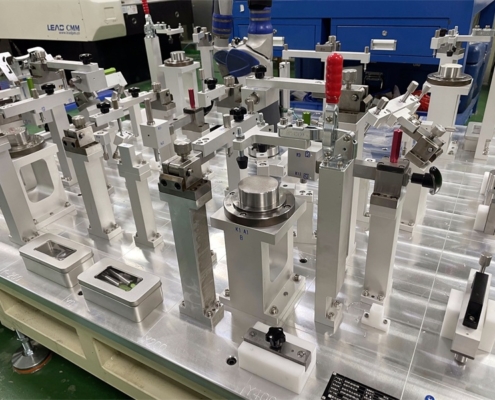

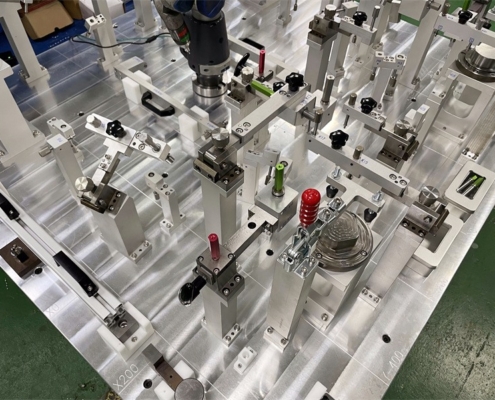

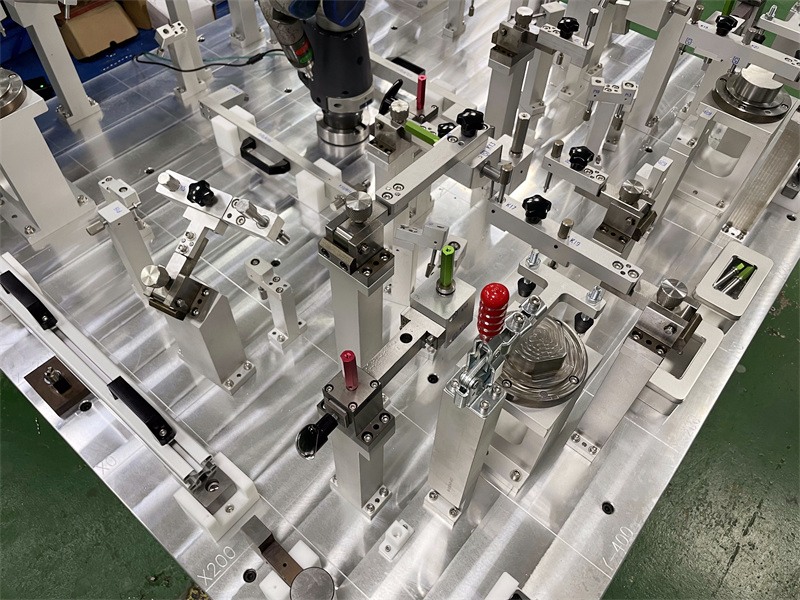

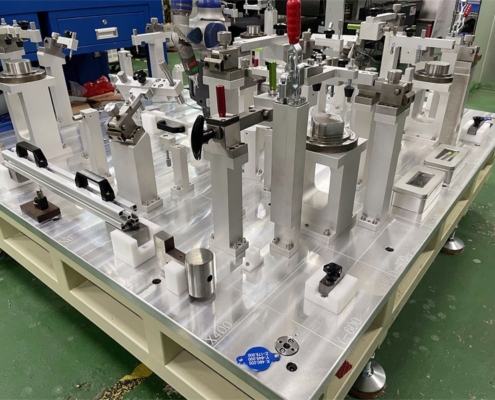

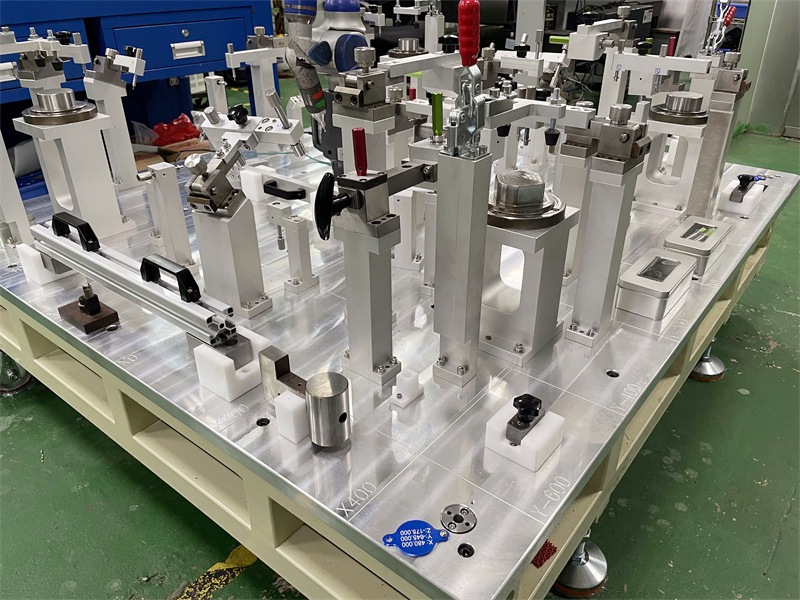

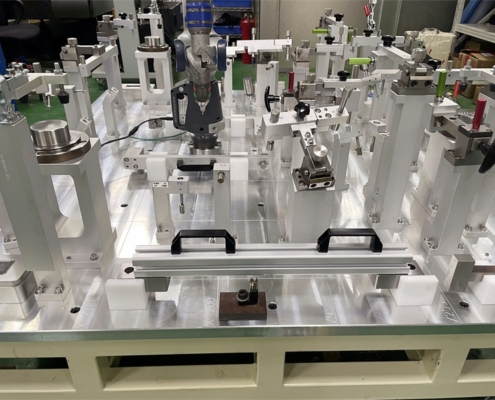

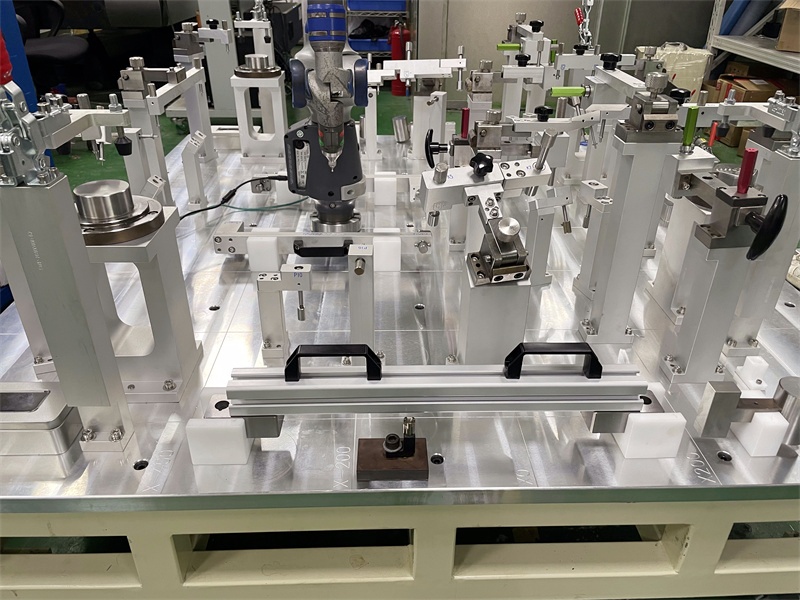

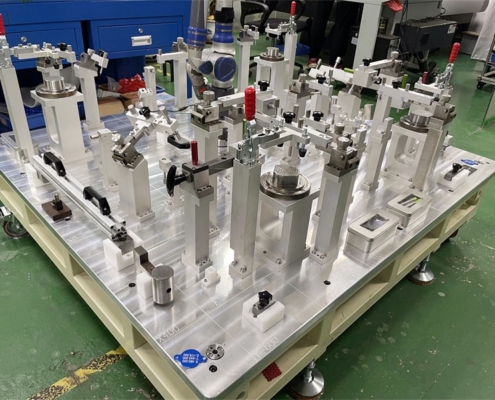

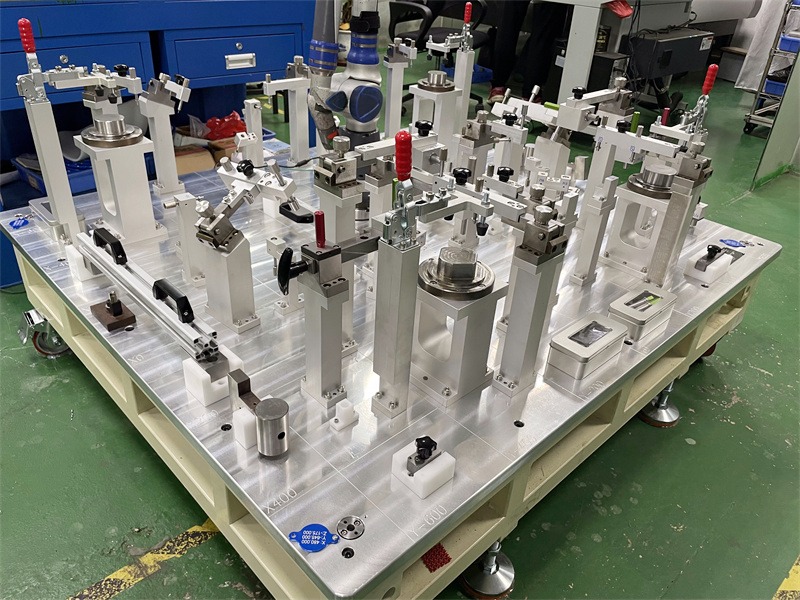

A coordinate measuring checking fixture is a precision tool used with CMMs (Coordinate Measuring Machines) to ensure accurate and repeatable measurements of parts. It provides stable positioning, alignment, and clamping, critical for quality control in manufacturing.

Reduce Inspection Time by 40% with Automated Features

Our automotive checking fixtures can be categorized into three types based on the inspection object:

- Stamping Single-Part Checking Fixture

(For inspecting individual stamped components)

- Subassembly Checking Fixture

(For verifying assemblies composed of multiple parts)

- Modular Integrated Checking Fixture

(Designed for complex systems combining multiple subassemblies)

Key Features:

1 Stamping Single-Part Checking Fixture

- Precision Alignment: Ensures accurate positioning of stamped parts with micron-level tolerance

- Modular Design: Quick-change tooling adapts to various part geometries

- Real-Time Feedback: Integrated sensors provide instant dimensional verification

2 Subassembly Checking Fixture

- Multi-Point Verification: Simultaneously checks critical interfaces between 5-10 components

- Kinematic Mounting: Maintains assembly relationships during dimensional inspection

- Traceability Integration: Automatically records measurement data for quality audits

3 Modular Integrated Checking Fixture

- System-Level Validation: Verifies functional alignment of complete vehicle subsystems

- Adaptive Clamping: Pneumatic/hydraulic actuators accommodate complex geometries

- Robotic Compatibility: Designed for automated loading/unloading in smart factories

Technical Specifications:

- Processing Precision: Ensures high-level accuracy during the checking process.

- Accuracy for Other Profiles: Ideal for single stamping, assembly, and casting checking fixtures.

- Datum Hole Accuracy: +/- 0.05mm, ensuring precise measurements for critical dimensions.

- Material: Made from top-grade materials to ensure reliability and durability.

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

Auto Checking Fixture Standard Part Measurement concept

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF