How Advanced Checking Fixtures Improve Automotive Manufacturing Quality

Introduction

In automotive manufacturing, component precision directly affects vehicle safety and performance. Traditional methods struggle with three critical challenges:

- Complex curved surfaces challenging for rapid measurement

- Manual inspections prone to human error and inefficiency

- Stringent tolerances driving up rework expenses

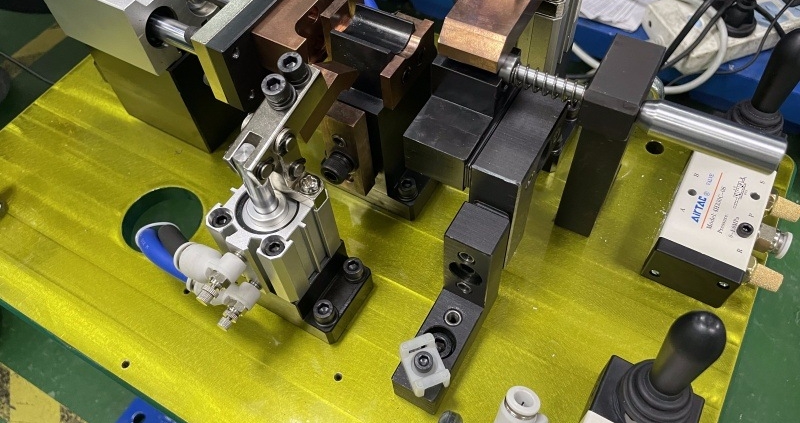

Advanced checking fixtures solve these issues through:

✅ Modular, adaptable designs

✅ Digital integration capabilities

✅ Strict GD&T (Geometric Dimensioning & Tolerancing) compliance

Quality Challenges in Automotive Manufacturing

Automotive production requires micron-level accuracy—a 0.1mm deviation can compromise safety. While manual measurements risk inconsistencies, precision inspection fixtures:

- Deliver ±0.005mm repeatability

- Cut inspection time by 50-70%

- Ensure full IATF 16949/ISO 9001 traceability

Core Advantages of Automotive Checking Fixtures

✅ Sub-Micron Accuracy

- Adapt to complex geometries (body panels, engine blocks)

- Compatible with CMM calibration and 3D scanning

- Generate ISO-certified inspection reports

✅ Production Line Optimization

- Reduce first-article inspection (FAI) time by 40%

- Slash rework costs via early defect detection

- Support high-volume batch testing

✅ Error-Proof Workflows

Eliminate manual data entry errors

Standardize operator procedures across shifts

Enable cloud-based data archiving

Automotive Applications

🔧 Body-in-White Inspection

- Validate door/window alignment gaps (≤±0.2mm)

- Detect stamping deformations in hoods/fenders

⚙️ Powertrain Quality Control

- Verify engine block bore concentricity

- Ensure transmission housing flatness (≤0.01mm/m²)

🔩 Chassis Component Validation

- Check suspension mounting hole positions

- Monitor welding seam consistency

Selecting the Right Fixture: 3 Key Factors

✅Custom Engineering

- Designed from 3D CAD models

- Material options: Aircraft-grade aluminum/Stainless steel

✅ Smart Integration

- Compatible with CMMs/laser trackers/vision systems

- Optional IoT-enabled real-time monitoring

✅Certified Compliance

- Meets VDA 6.3/AIAG CQI-15 standards

- Includes NIST-traceable calibration certificates