User Case:

BYD Company

Company Overview: BYD Company Ltd. is a leading Chinese manufacturer of automobiles, battery-powered bicycles, buses, forklifts, solar panels, rechargeable batteries, and trucks. Known for its commitment to sustainable energy solutions, BYD has made significant strides in the electric vehicle (EV) market, becoming one of the largest EV manufacturers globally.

Challenge: As BYD continues to expand its production of electric vehicles, maintaining high standards of quality and precision in manufacturing processes is critical. The company faced the challenge of ensuring that all components, from battery packs to electric motors, met stringent quality requirements. This necessitated the implementation of advanced inspection solutions to verify the accuracy and integrity of various parts throughout the production line.

Solution: BYD partnered with HUI ZHOU P&A ACCURATE TECHNOLOGY CO., LTD to integrate high-precision automotive checking fixtures into their manufacturing process. These fixtures were specifically designed to meet the needs of BYD’s electric vehicle assembly, providing precise and reliable inspection of critical components.

Implementation:

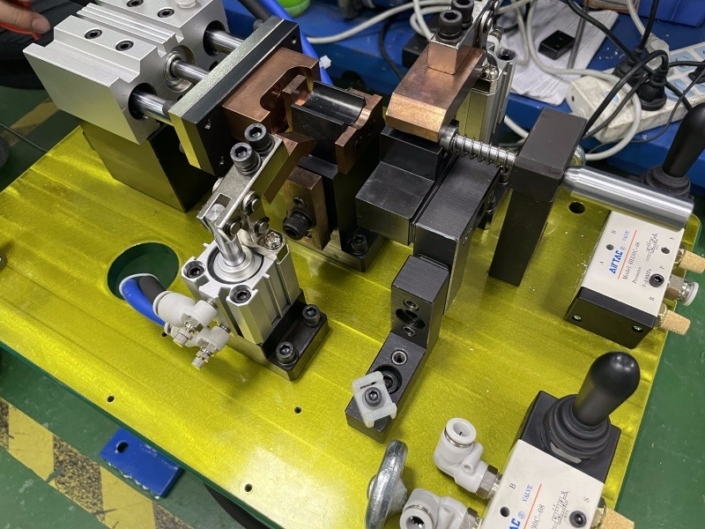

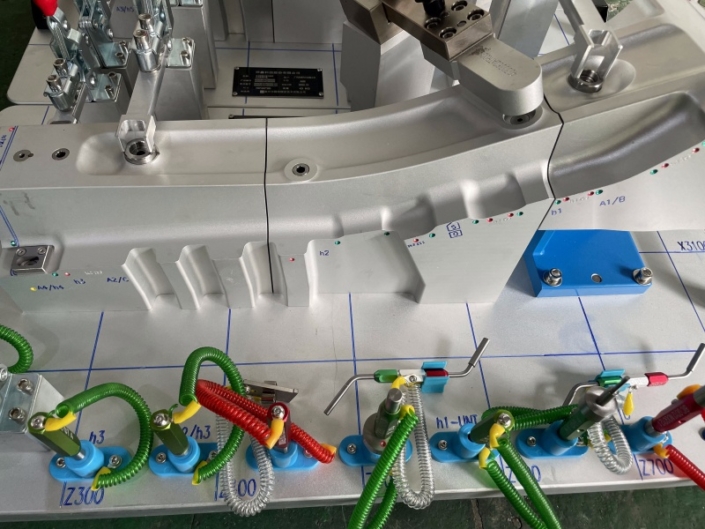

- Custom Design: Tailored checking fixtures were designed to meet the specific requirements of BYD’s electric vehicle components, including battery packs, electric motors, chassis, and body panels.

- High Precision: The fixtures were engineered to provide exceptional accuracy, ensuring that every component met BYD’s exacting standards.

- Durability and Reliability: Constructed from high-quality materials, the fixtures were built to withstand the demanding conditions of BYD’s production environment.

- Ease of Use: User-friendly designs simplified the inspection process, reducing setup times and increasing overall efficiency.

Key Features of the Checking Fixtures:

- Battery Pack Inspection: Ensuring precise alignment and secure installation of battery cells and modules.

- Electric Motor Verification: Facilitating accurate positioning and mounting of electric motors.

- Chassis and Body Panel Inspection: Providing robust support and alignment for chassis components and body panels.

- Quality Control Integration: Seamlessly integrating into BYD’s existing quality control processes for comprehensive inspections.

Results:

- Improved Quality Control: The integration of high-precision checking fixtures led to significant improvements in the quality and consistency of BYD’s electric vehicle components.

- Increased Efficiency: Streamlined inspection processes reduced production cycle times, enhancing overall productivity.

- Enhanced Reliability: The durability and accuracy of the fixtures ensured that all parts met the required standards, reducing the likelihood of defects and rework.

- Customer Satisfaction: The enhancements in quality control contributed to higher levels of customer satisfaction and reinforced BYD’s reputation for producing reliable and high-quality electric vehicles.

Insight and News

Explore the latest article and insight from P&A Accurate

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |