Introduction

The manufacturing industry is undergoing a seismic shift, driven by automation, digitalization, and sustainability. At the heart of this transformation lies checking fixtures—critical tools that ensure precision, quality, and efficiency in production lines. In this blog, we dive into the cutting-edge advancements and future trends reshaping the checking fixtures landscape, offering actionable insights for manufacturers aiming to stay competitive.

1. AI-Driven Automation in Checking Fixtures

Artificial Intelligence (AI) is no longer a buzzword—it’s revolutionizing quality control. Modern checking fixtures now integrate AI-powered sensors and machine learning algorithms to analyze data in real time. These systems detect deviations as small as microns, predict equipment wear, and even self-calibrate, reducing human error and speeding up inspection cycles. For industries like automotive and aerospace, where precision is non-negotiable, AI-enabled fixtures are becoming indispensable.

2. The Rise of Hybrid Fixtures: Combining Physical and Digital

The future of checking fixtures lies in hybrid designs that merge physical tools with digital twins. Using 3D scanning and augmented reality (AR), engineers can overlay digital models onto physical fixtures to validate designs before production. This approach slashes prototyping costs and accelerates time-to-market. Companies like BMW and Boeing already leverage hybrid fixtures to maintain rigorous quality standards while adapting to rapid design changes.

3. Lightweight, Eco-Friendly Materials Take Center Stage

Sustainability is reshaping fixture manufacturing. Traditional steel fixtures are being replaced by carbon fiber composites and recyclable polymers. These materials are not only lighter (reducing energy consumption in handling) but also durable enough to withstand high-pressure environments. Additionally, manufacturers are adopting eco-conscious processes, such as 3D printing with biodegradable resins, to minimize waste.

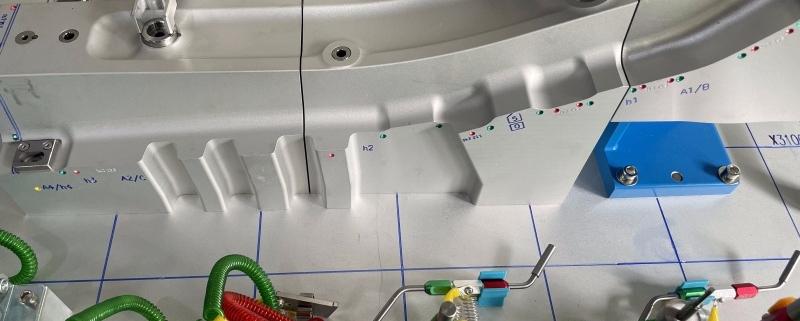

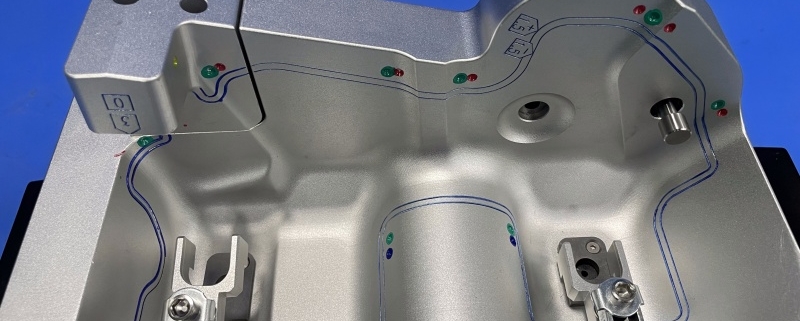

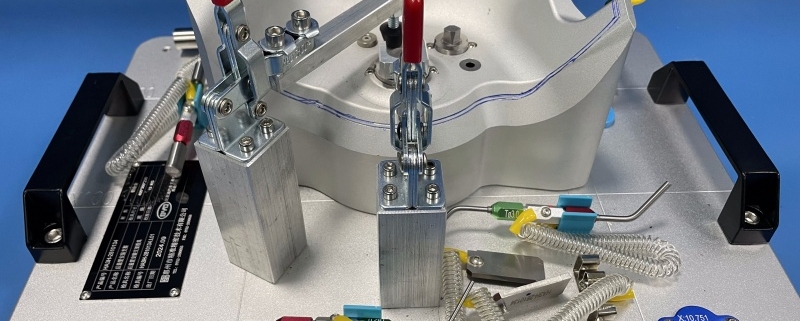

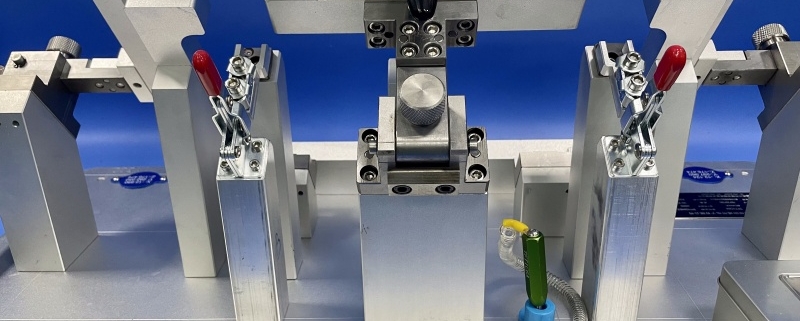

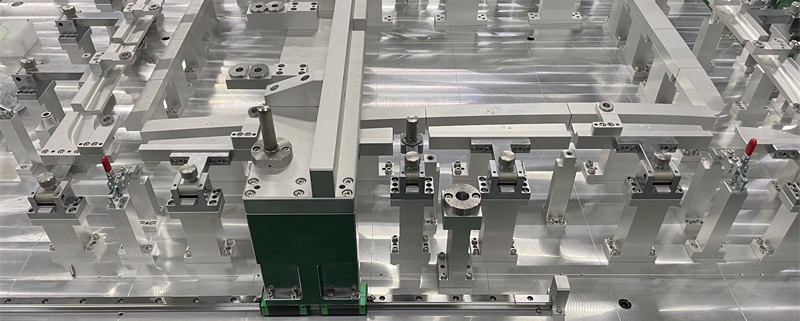

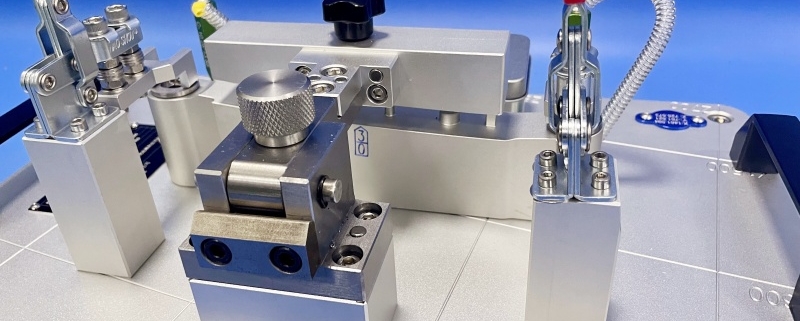

4. Modular Fixtures for Flexible Manufacturing

As demand for customized products grows, modular checking fixtures are gaining traction. These fixtures feature interchangeable components that can be reconfigured for different parts or assembly lines. For example, a single modular fixture might adapt to inspect both engine components and electronic housings, maximizing ROI for manufacturers juggling diverse product portfolios.

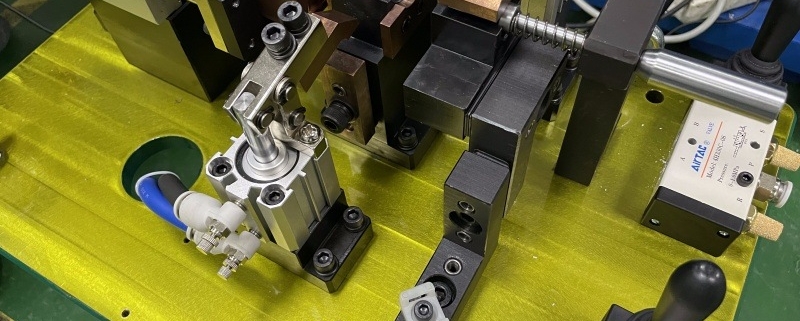

5. Robotics and Collaborative Fixture Systems

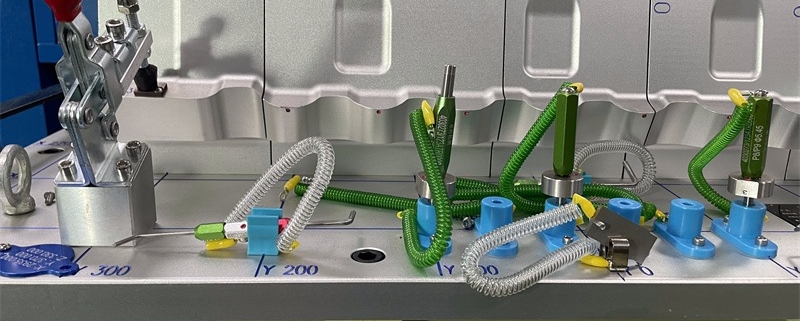

Collaborative robots (cobots) are teaming up with checking fixtures to streamline workflows. Equipped with vision systems and grippers, cobots can position parts onto fixtures, perform inspections, and flag defects—all without human intervention. This synergy boosts throughput and allows human workers to focus on higher-value tasks like data analysis and process optimization.

6. The Role of Big Data in Predictive Maintenance

Data is the new oil, and checking fixtures are no exception. Embedded IoT sensors collect terabytes of data on fixture performance, environmental conditions, and part tolerances. By applying predictive analytics, manufacturers can schedule maintenance before a fixture fails, avoiding costly downtime. For instance, a sensor detecting abnormal vibration in a fixture might trigger an alert, prompting preemptive repairs.

7. Global Standards and Regulatory Shifts

As industries globalize, adherence to international quality standards (e.g., ISO 9001, AS9100) is paramount. Future checking fixtures will need built-in compliance features, such as automated audit trails and traceability protocols. Regulatory bodies are also pushing for stricter tolerances in sectors like medical devices, driving innovation in ultra-precision fixtures.

Conclusion

The future of checking fixtures is dynamic, driven by AI, sustainability, and adaptability. Manufacturers who embrace these trends will not only enhance product quality but also future-proof their operations against evolving market demands.

Call to Action

Ready to upgrade your quality control processes? Explore our next-generation checking fixtures or contact our experts for a tailored solution. Don’t forget to subscribe to our newsletter for monthly insights on manufacturing innovations!