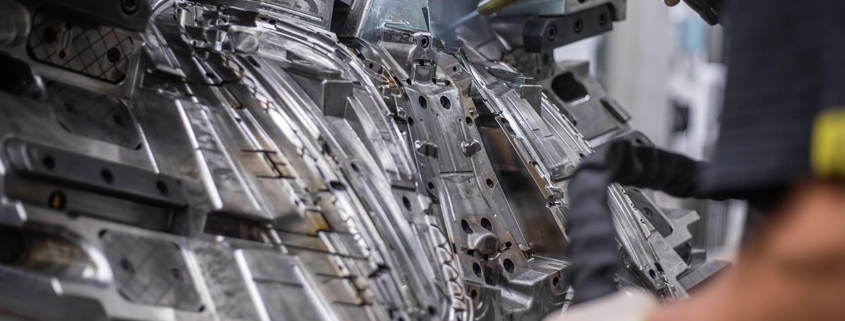

In the ever-evolving automotive industry, precision and quality are non-negotiable aspects that determine the success of any manufacturer. To stay ahead in this competitive landscape, it’s crucial to invest in advanced tools that enhance efficiency and accuracy, such as automotive checking fixtures. These fixtures are the unsung heroes of the production line, ensuring that every component meets the highest standards before it becomes part of a vehicle.

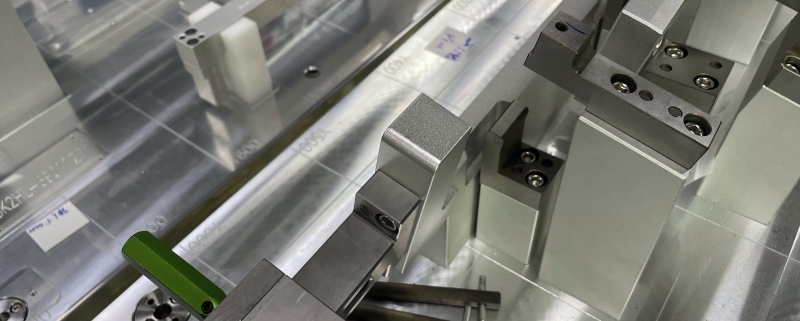

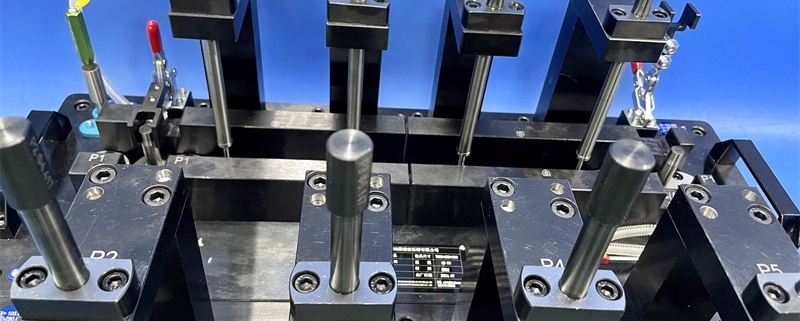

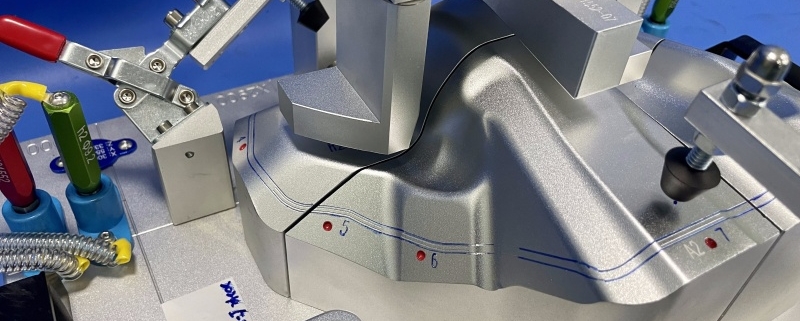

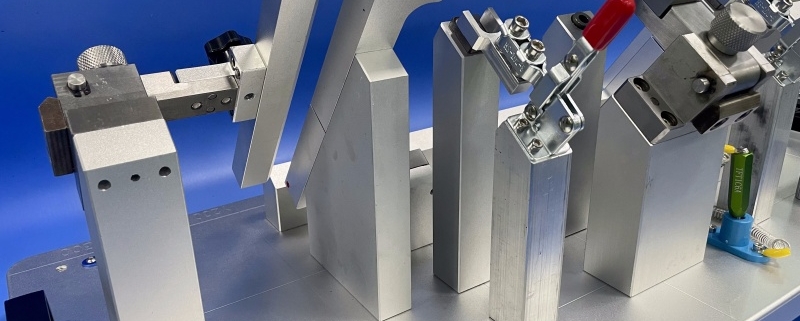

Automotive checking fixtures are designed to provide meticulous assessments of various parts, identifying even the slightest deviations from specified standards. By leveraging cutting-edge technology, these fixtures streamline quality control processes, preventing potential issues and ensuring customer satisfaction.

Moreover, these fixtures are versatile and can be customized to suit the unique needs of different automotive manufacturers. From assessing the dimensions of engine components to evaluating the fit and finish of exterior parts, automotive checking fixtures offer unparalleled precision and reliability. By embracing innovation and investing in these fixtures, automotive manufacturers can elevate their production processes, enhance their online presence, and ultimately drive success in the competitive automotive market.