How do automotive inspection tools detect automotive components

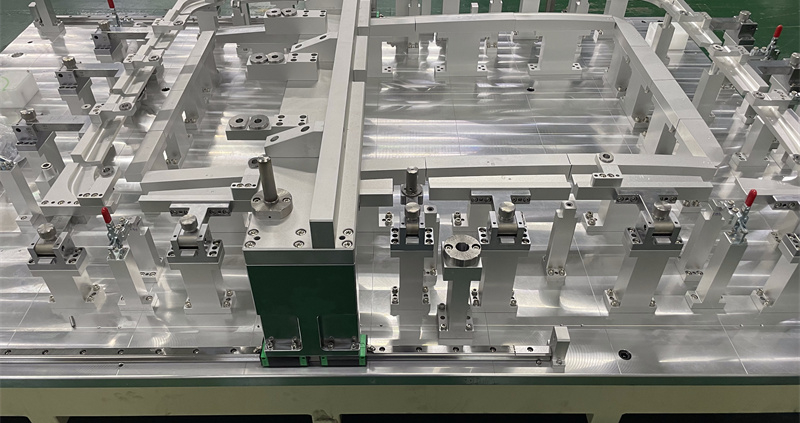

Automotive inspection tools employ a multifaceted approach to detect and assess automotive components. Initially, a thorough visual inspection is conducted, examining the component’s exterior for any signs of damage, rust, or discrepancies in appearance. This is coupled with verification of safety features and alignment with specified data, such as serial numbers.

Subsequently, precise measurements are taken using calibrated instruments to ensure that dimensions and tolerances adhere to technical standards. Performance tests are also conducted to validate the component’s operational efficiency.

Furthermore, advanced techniques like magnetic particle inspection, penetrant testing, and ultrasonic inspection are utilized to detect internal defects that may not be visible externally.