What Is an Inspection Fixture?

Definition

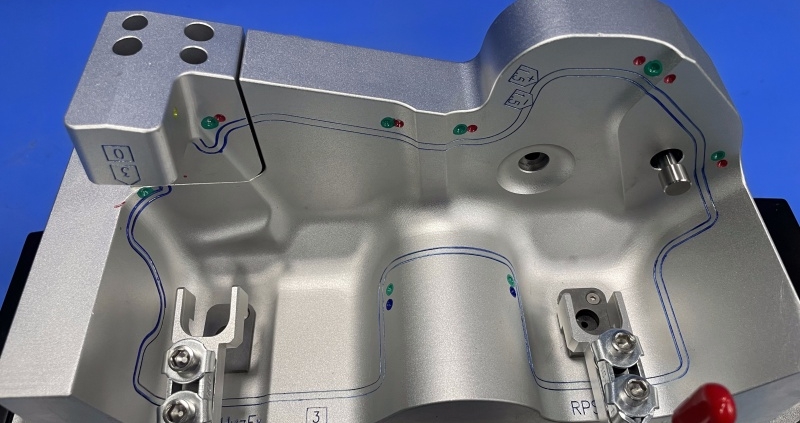

An inspection fixture (or checking fixture) is a precision tool used in manufacturing to verify part dimensions, quality, and compliance with design specs. It’s essential in industries like automotive, aerospace, electronics, and medical devices.

Why Use Inspection Fixtures?

- 5–10x faster than manual inspections

- Reduces errors in mass production

- Lowers costs by minimizing rework/scrap

- Ensures compliance with ISO 9001, IATF 16949, etc.

Types of Inspection Fixtures:

Modular Fixtures

- Adjustable for multiple parts

- Cost-effective for small batches

Dedicated Fixtures

- Custom-built for high precision (e.g., automotive/aerospace)

Automated Fixtures

- Integrated sensors for Industry 4.0 smart factories

Key Components

- Base Plate: Stability

- Locating Pins: Precise positioning

- Clamping Units: Secure parts

- Measuring Tools: Verify critical dimensions

- Data Port (optional): Digital QC reporting