Inspection Fixture vs. Checking Fixture: Understanding the Differences

Inspection Fixtures vs. Checking Fixtures: What’s the Difference?

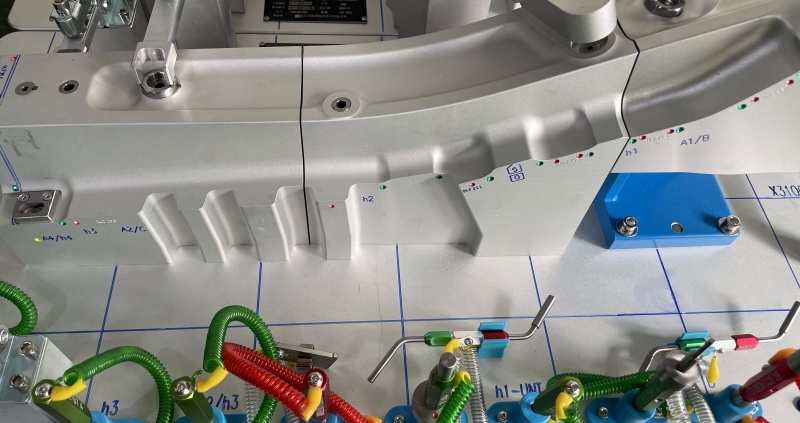

In manufacturing, inspection fixtures and checking fixtures are both used for quality control, but they serve different purposes.

1. Core Functions

- Inspection Fixture: Used for precise measurement (e.g., CMM verification). Common in aerospace & medical industries.

- Checking Fixture: Designed for quick pass/fail checks (e.g., shape verification). Often used in automotive & consumer electronics.

2. Key Differences

| Feature | Inspection Fixture | Checking Fixture |

|---|---|---|

| Accuracy | High (µm-level) | Medium (mm-level) |

| Usage | Lab/QC final inspection | Production line checks |

| Cost | Higher (custom designs) | Lower (standardized) |

3. How to Choose?

- Need detailed reports? → Inspection Fixture

- Need fast, repetitive checks? → Checking Fixture

4. Future Trends

- Smart sensors for real-time data

- Modular designs for flexible use

Inspection fixtures are for high-precision measurement, while checking fixtures handle quick pass/fail tests. Choosing the right one depends on accuracy needs, budget, and production speed. Smart, modular designs are the future of quality control.