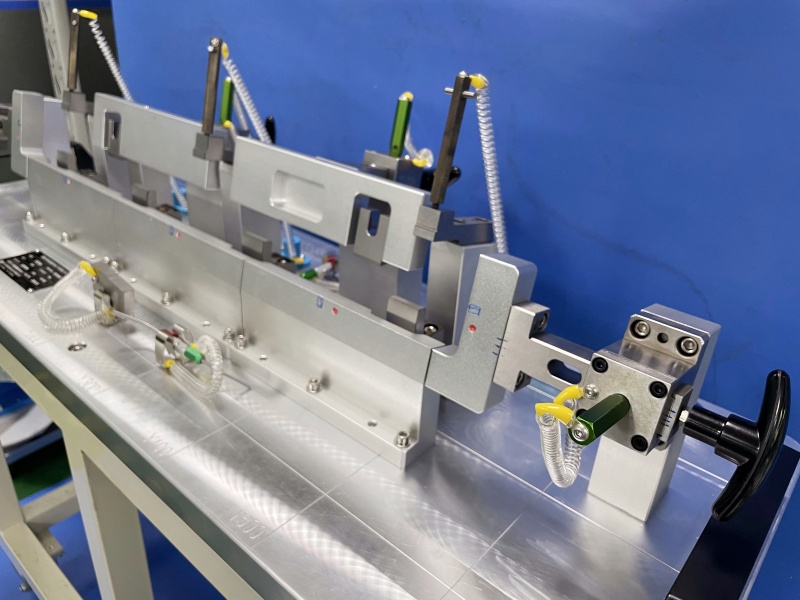

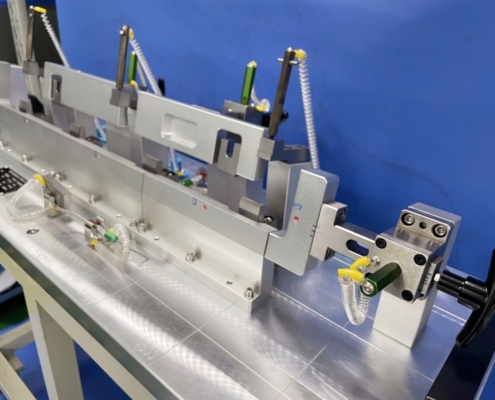

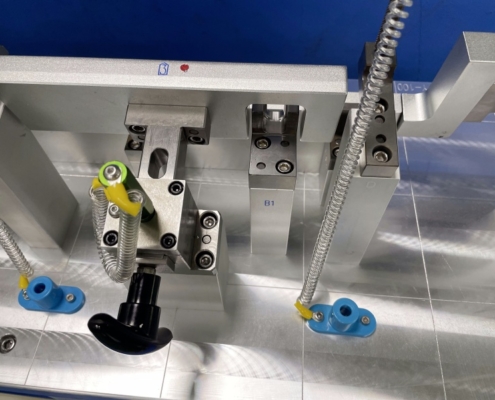

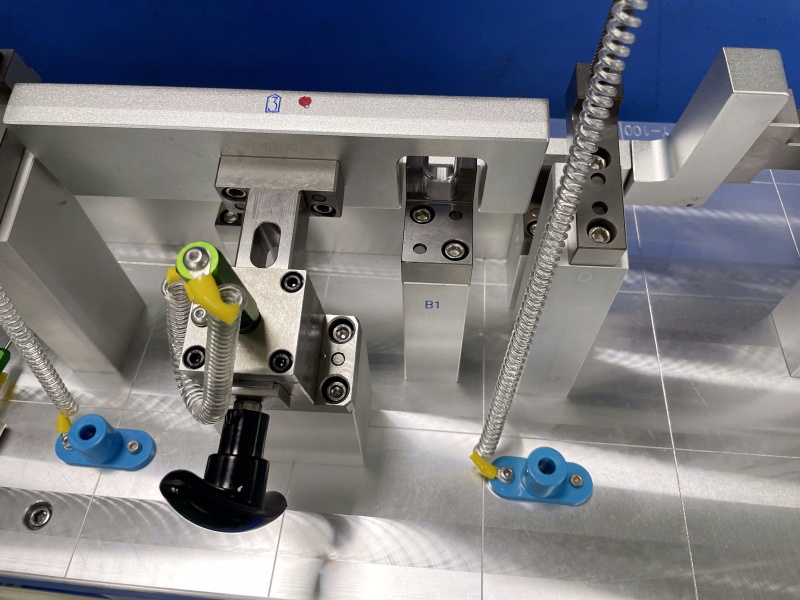

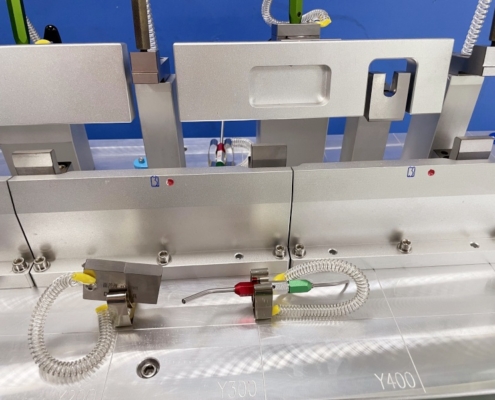

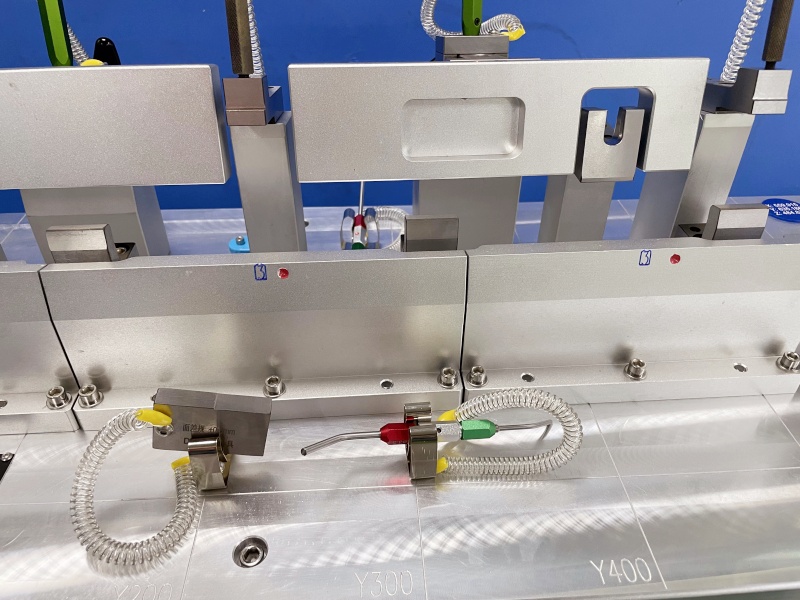

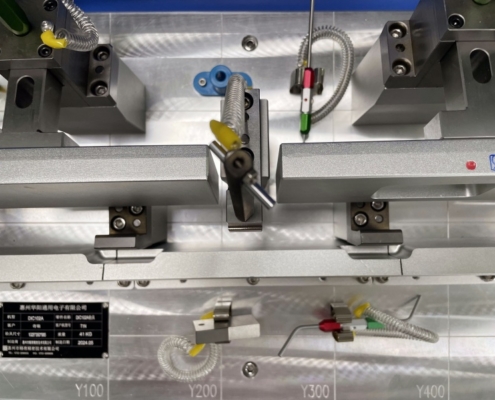

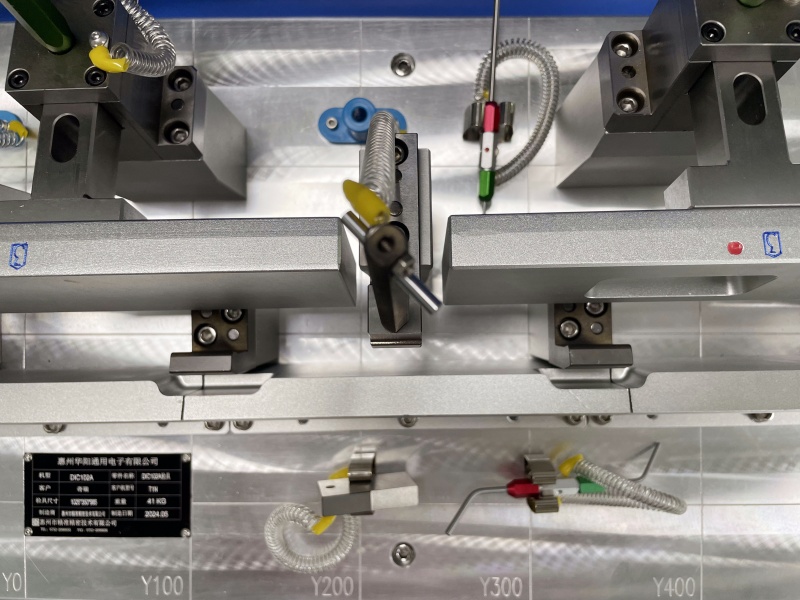

Our aluminum alloy checking fixtures provide the perfect balance of strength and lightweight performance for precision inspection applications. Engineered for automotive OEMs, aerospace suppliers, and precision manufacturers, these fixtures deliver repeatable accuracy within ±0.02mm while reducing operator fatigue.

Aluminum alloy checking fixtures

Our Aluminum Alloy Checking Fixture is a versatile and high-precision tool designed for a variety of checking needs, including:

- Single Metal Parts Checking Fixtures

- Casting Aluminium Parts Checking Fixtures

- Plastic Checking Fixtures

Key Features:

✔ Aerospace-Grade Aluminum Construction

- 6061-T6 aluminum alloy for optimal strength-to-weight ratio

- 40% lighter than steel fixtures while maintaining rigidity

- Anodized surface treatment for corrosion resistance

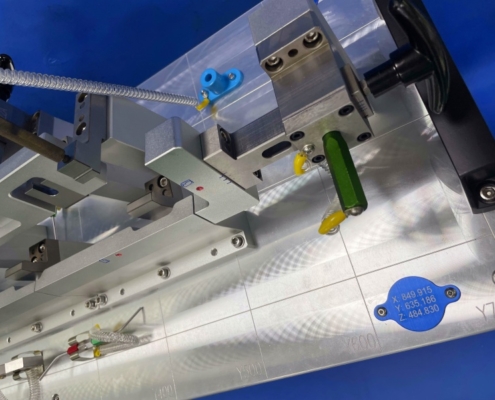

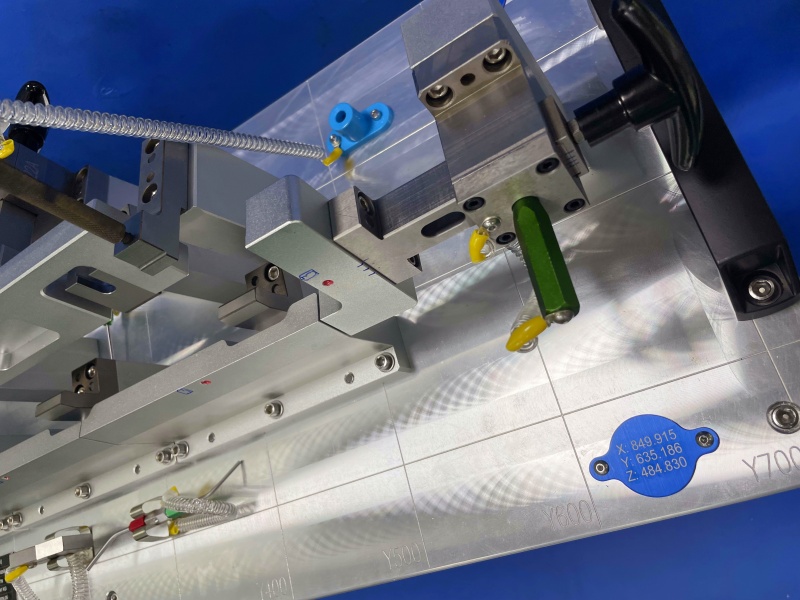

✔ Precision Engineering

- CNC-machined to GD&T standards (ASME Y14.5)

- ±0.02mm tolerance for critical dimension verification

- Modular design allows for quick configuration changes

✔ Industry-Specific Advantages

- Automotive: Ideal for BIW (Body-in-White) and powertrain inspection

- Aerospace: Perfect for composite component verification

- Medical Devices: Meets strict cleanroom requirements

✔ Smart Manufacturing Ready

- RFID tag mounting points for traceability

- IoT sensor integration capability

- Compatible with automated inspection systems

Technical Specifications:

| Parameter | Specification |

|---|---|

| Material | 6061-T6 aluminum alloy |

| Surface Finish | Hard anodized (25-50μm) |

| Max Load | 150kg (standard), 300kg (heavy-duty) |

| Temperature Range | -20°C to +120°C operating range |

| Compatibility | CMM, 3D scanners, vision systems |

| Certifications | ISO 9001, |

| Lead Time | 3-5 weeks for standard configurations |

Why Choose Our Aluminum Checking Fixtures?

1 Proven Performance

- Used by Tier 1 automotive suppliers and aerospace manufacturers

- 30% longer service life compared to standard aluminum fixtures

2 Cost-Effective Solution

- 50% faster setup time than traditional steel fixtures

- Reduced operator fatigue = higher productivity

3 Custom Engineering Support

- Free DFM (Design for Manufacturability) analysis

- CAD/CAM integration (SolidWorks, CATIA, NX)

4 Global Support Network

- On-site calibration services available

- 24/7 technical support

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF