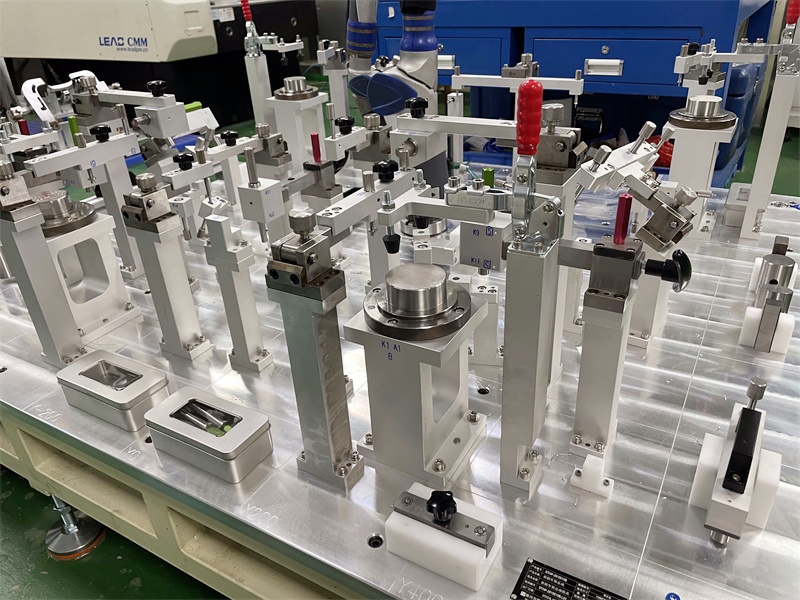

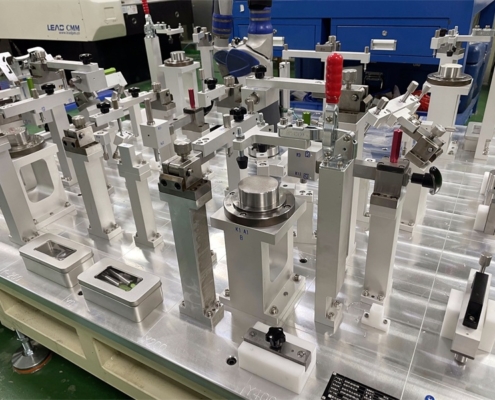

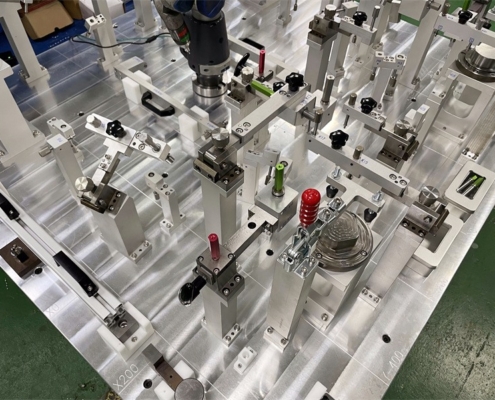

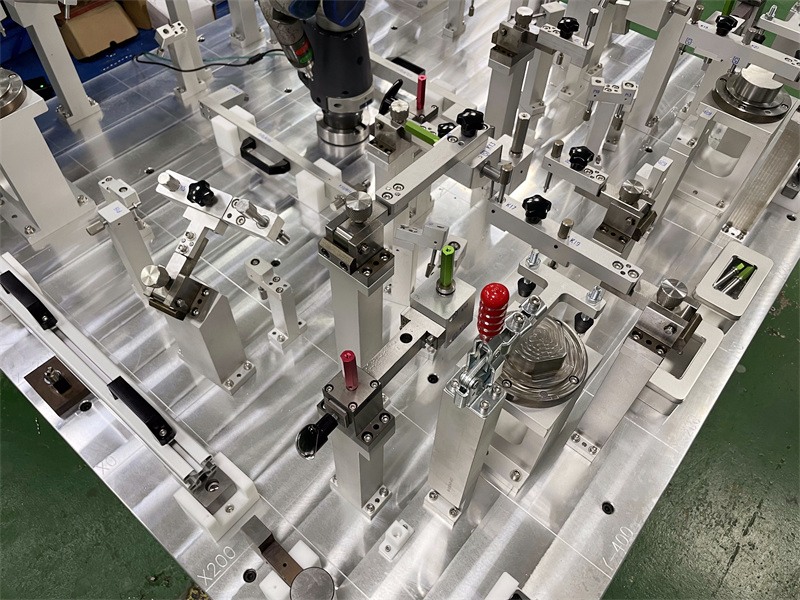

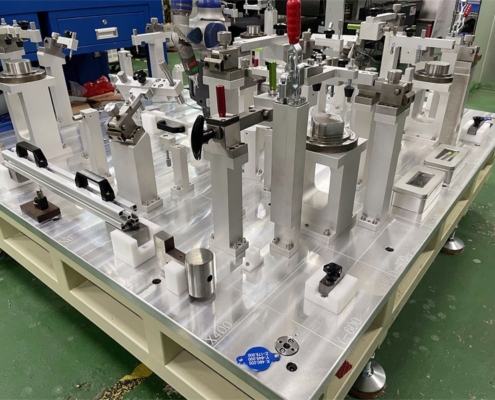

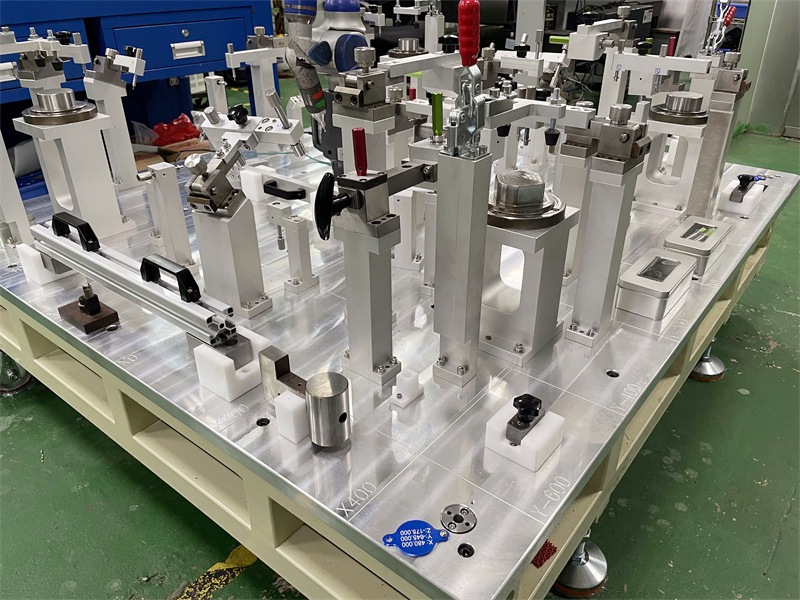

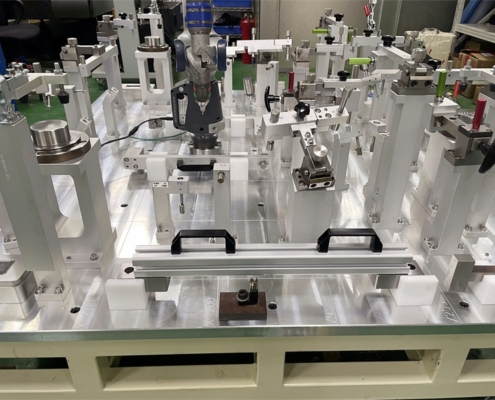

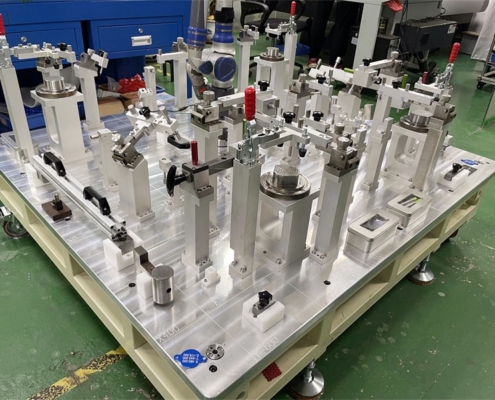

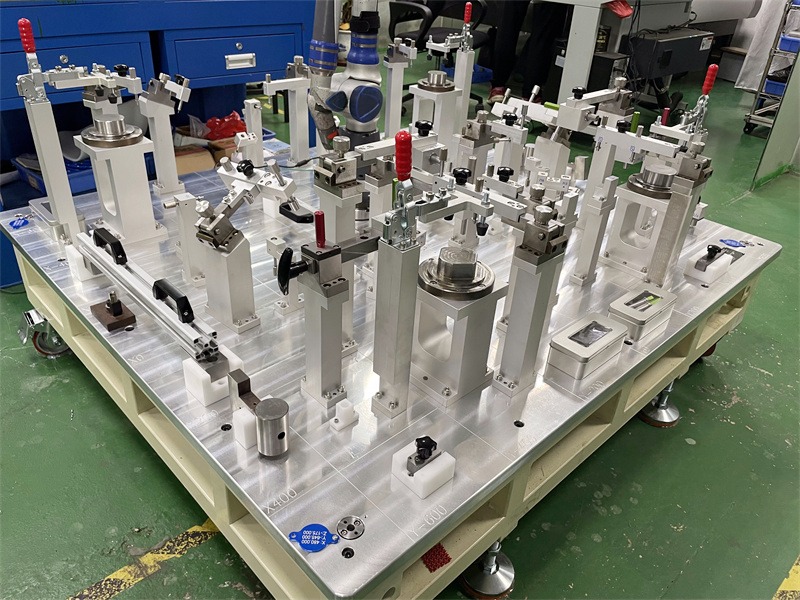

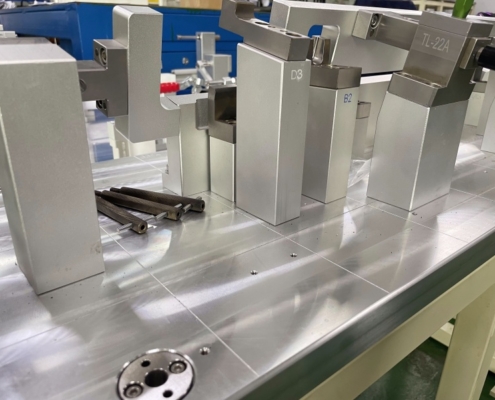

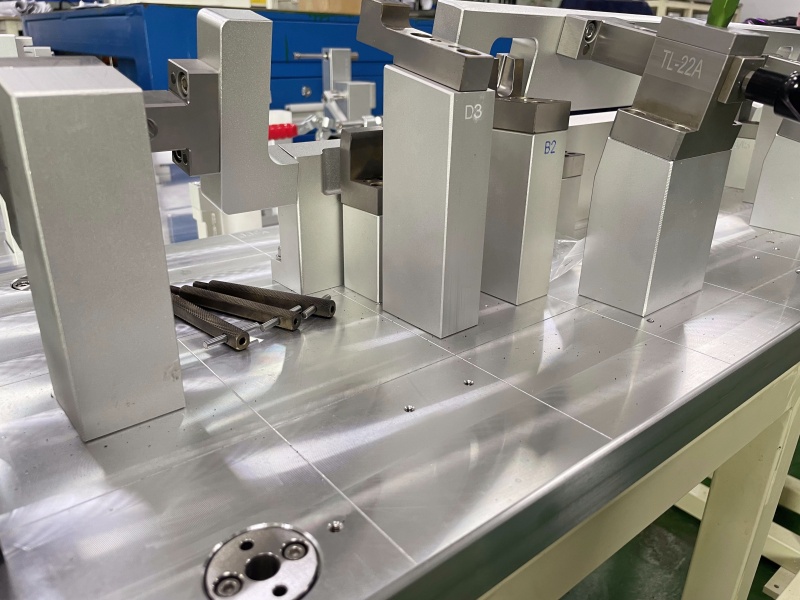

Custom checking fixtures/jigs ensure 100% accurate dimensional, positional & functional measurements for gears, body panels, molds, etc. Designed for automotive OEMs, mold manufacturers & assembly lines, with ±0.02mm tolerance

Key Features (Technical Credibility)

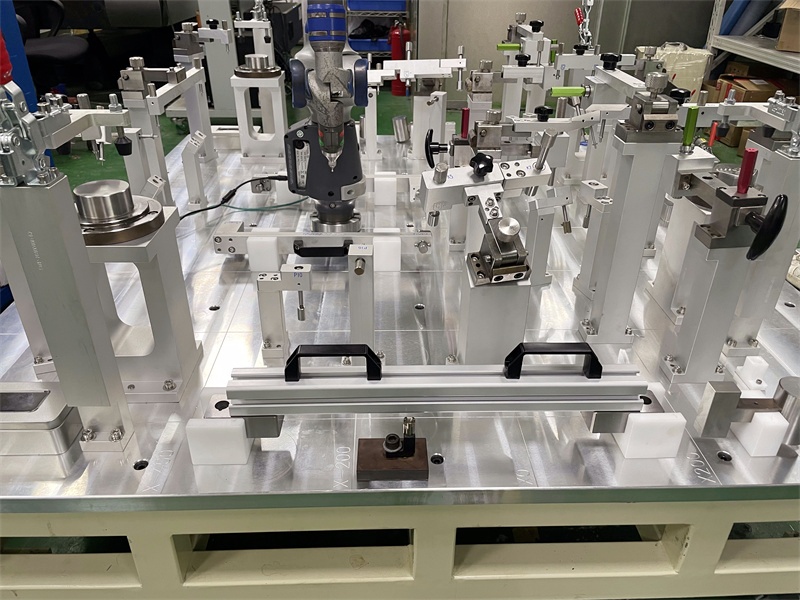

✔ High-Accuracy Measurement – Detect micron-level deviations in holes, contours, and assemblies.

✔ Custom-Built for Your Parts – Tailored to fit your component’s unique geometry (3D scan/CAD support).

✔ Durable & Repeatable – Made from hardened steel/aluminum for long-term stability.

✔ Fast Inspection Cycles – Reduce testing time by 30%+ vs. manual methods.

✔ GD&T & ISO Compliance – Meet industry standards for critical reports.

Target Applications (Match Customer Needs)

Our auto precision checking fixtures are used for:

- Mold Components – Validate cavity/core dimensions post-machining.

- Transmission Parts – Check gear tooth profiles and alignment.

- Body-in-White (BIW) – Verify welding points and panel gaps.

- Electronics Housings – Test connector fitment and sealing surfaces.

Why Choose Us

Unlike generic fixtures, we:

- Collaborate with your engineering team to optimize design for your QA process.

- Provide full documentation (inspection reports, CAD models).

- Offer rapid prototyping – 15-day lead time for urgent projects.

- Support CMM integration for automated data collection.

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

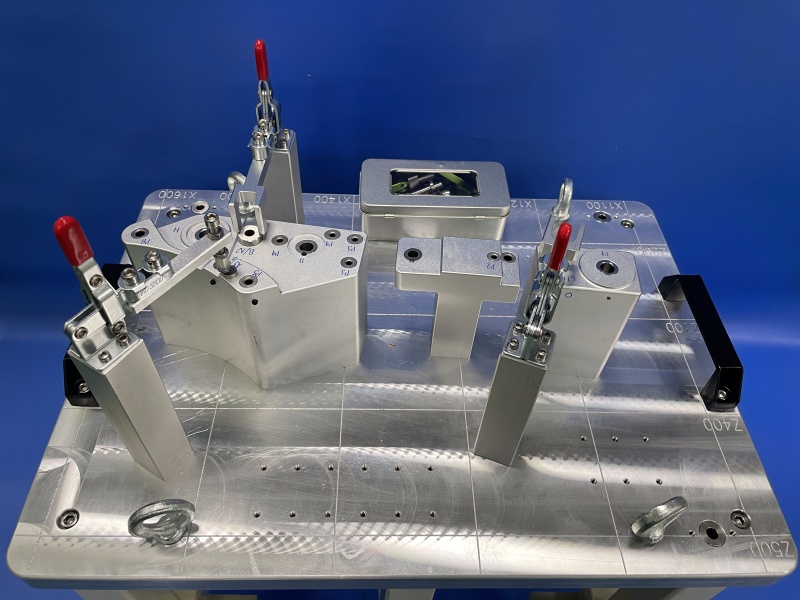

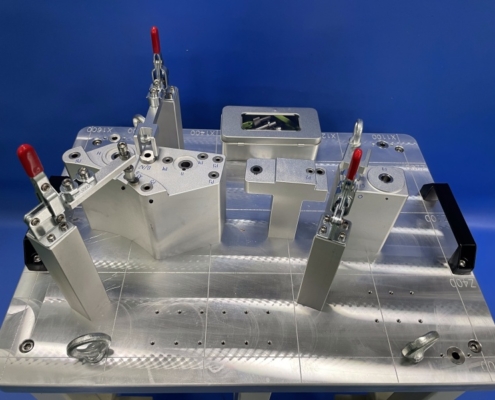

Sheet metal panel checking fixture for single auto parts

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Auto Checking Fixture Standard Part

The sheet metal panel checking fixture is a tool used to check the size and shape of sheet metal parts. It helps ensure they are made correctly and fit well. This tool is important in car manufacturing and other industries where accuracy is key.

Auto Checking Fixture Standard Part Measurement concept

This fixture checks sheet metal panels for correct size and shape. Essential for accurate manufacturing, especially in the automotive industry.

Checking Fixture is a versatile and high-precision tool designed for a variety of checking needs, including:

- Single Metal Parts Checking Fixtures

- Casting Aluminium Parts Checking Fixtures

- Plastic Checking Fixtures

Key Features:

- Versatile Applications: Suitable for checking single metal parts, aluminum casting parts, and plastic components.

- High Precision: Designed for processing precision, ensuring that every measurement is accurate.

- Durability: Constructed from high-quality materials to withstand rigorous use and ensure longevity.

- Ease of Use: User-friendly design simplifies the checking process, reducing setup time and increasing efficiency.

Technical Specifications:

- Processing Precision: Ensures high-level accuracy during the checking process.

- Accuracy for Other Profiles: Ideal for single stamping, assembly, and casting checking fixtures.

- Datum Hole Accuracy: +/- 0.05mm, ensuring precise measurements for critical dimensions.

- Material: Made from top-grade materials to ensure reliability and durability.

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF