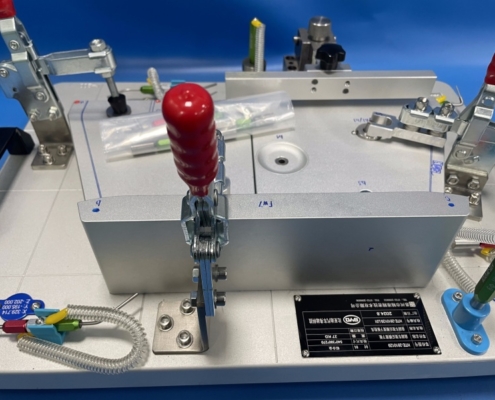

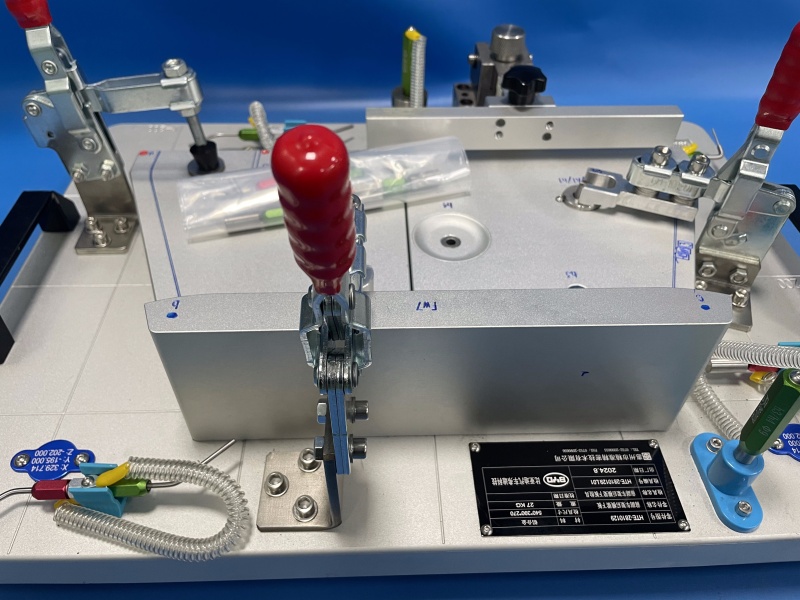

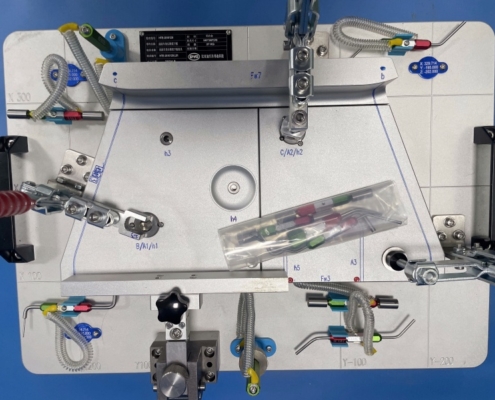

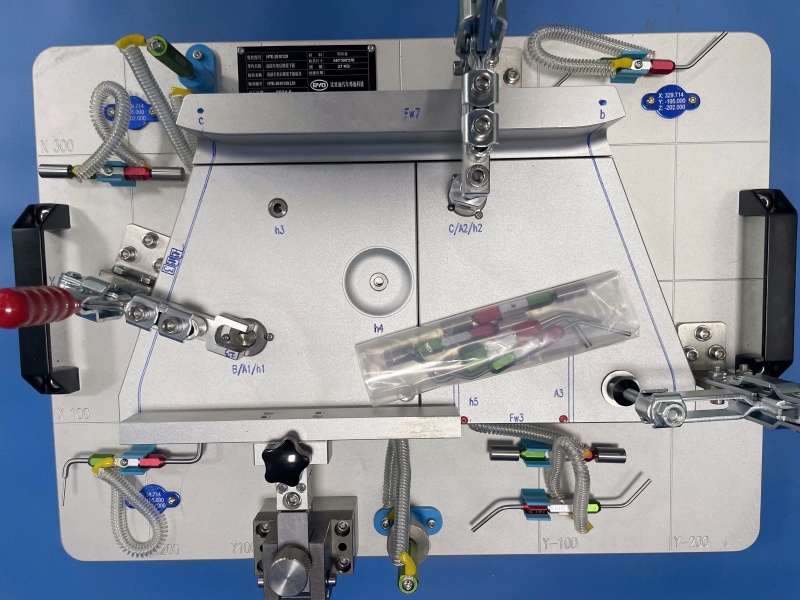

Our high-precision checking fixtures (inspection fixtures) are engineered for mold manufacturers, automotive component suppliers, and assembly plants requiring ultra-precise dimensional, positional, and functional verification. Every fixture is custom-built to your CAD data, ensuring flawless quality control for tight-tolerance parts.

Precision Automotive Inspection Fixtures – Custom Quality Control Solutions

Our Automotive Fixturing inspection Tools can be categorized into three types based on the inspection object:

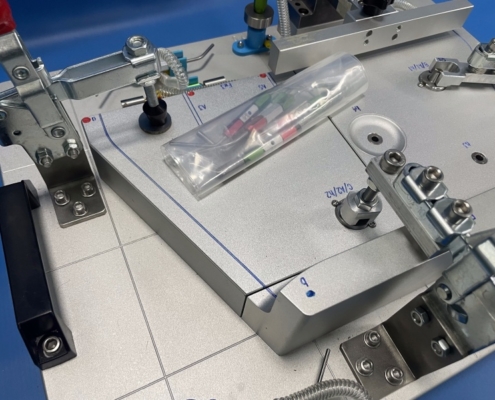

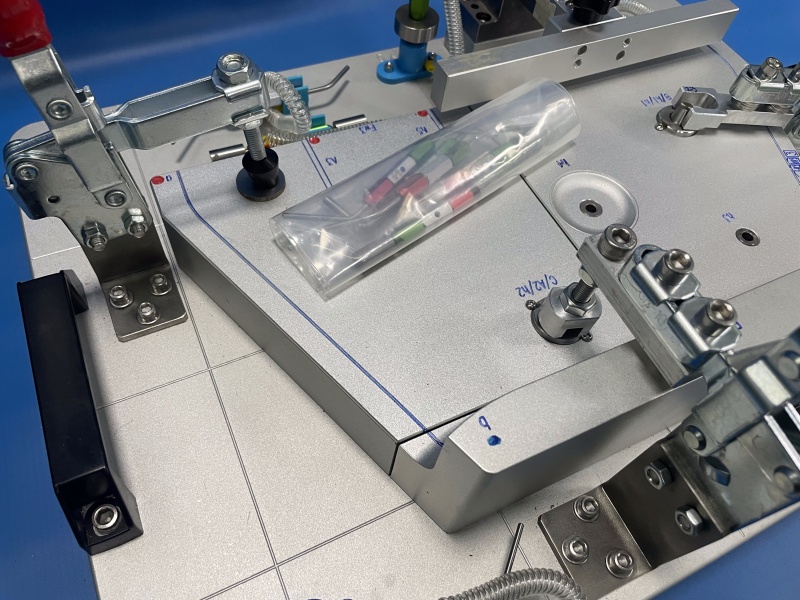

- Stamping Single-Part Checking Fixture

(For inspecting individual stamped components)

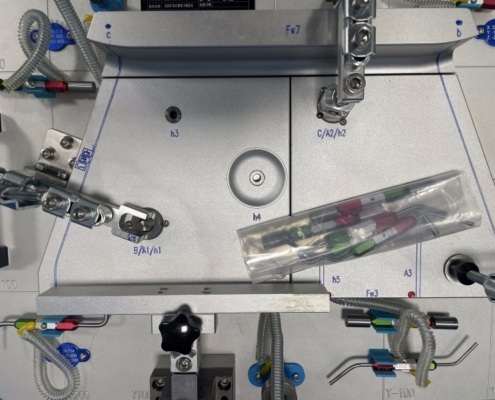

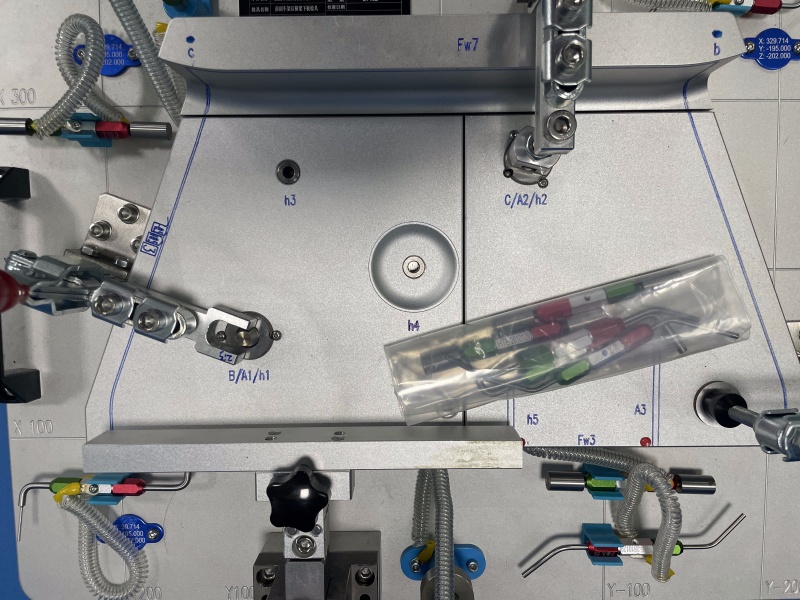

- Subassembly Checking Fixture

(For verifying assemblies composed of multiple parts)

- Modular Integrated Checking Fixture

(Designed for complex systems combining multiple subassemblies)

Key Features:

1 Multi-Parameter Verification

- Simultaneously check critical dimensions, geometric tolerances (GD&T), and functional performance in a single setup

- Integrated sensors for runout, concentricity, perpendicularity, and surface finish analysis

2 Modular Design Flexibility

- Customizable fixture platforms adaptable to diverse component geometries

- Quick-change tooling systems for multi-variant production lines

- Scalable solutions for prototype testing to high-volume manufacturing

3 Smart Data Integration

- IoT-enabled systems for real-time SPC data collection

- Automated reporting with digital measurement certificates

- Traceability features compliant with IATF 16949 standards

Technical Specifications:

- Processing Precision: Ensures high-level accuracy during the checking process.

- Accuracy for Other Profiles: Ideal for single stamping, assembly, and casting checking fixtures.

- Datum Hole Accuracy: +/- 0.05mm, ensuring precise measurements for critical dimensions.

- Material: Made from top-grade materials to ensure reliability and durability.

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF