Checking Fixture Components are precision-engineered tools used to validate critical dimensions, assembly fit, and functional compliance of automotive parts (e.g., body panels, engine mounts, electrical housings) against OEM specifications.

Checking Fixture Components: Precision Engineered for Flawless Automotive Inspections

Checking fixture components are precision-engineered tools used in the automotive industry to ensure the accuracy and quality of vehicle parts during manufacturing and assembly. These components are essential for verifying the dimensions, shapes, and tolerances of automotive parts, ensuring they meet strict industry standards.

Key Features:

- Durability: Made from high-quality materials such as aluminum, steel, and composite materials to withstand rigorous use.

- Customizable: Tailored to fit specific part geometries and inspection requirements.

- Modular Design: Allows for easy assembly, disassembly, and reconfiguration.

- Ergonomic: User-friendly design for efficient operation and reduced inspection time.

Technical Specifications

- Material: Aluminum, steel, or composite materials.

- Tolerance: ±0.05mm to ±0.1mm, depending on application.

- Surface Finish: Smooth, corrosion-resistant coating for longevity.

- Weight: Lightweight yet robust for easy handling.

- Compatibility: Compatible with various automotive parts, including body panels, chassis components, and interior parts.

Applications

Checking fixture components are widely used in:

- Automotive manufacturing and assembly lines.

- Quality control and inspection processes.

- Prototype development and testing.

- Aftermarket parts verification.

Customization Process

- Consultation: Discuss your specific requirements with our engineering team.

- Design: Our experts create a 3D model and technical drawings based on your needs.

- Prototyping: Develop a prototype for testing and validation.

- Production: Manufacture the final product using advanced CNC machining and fabrication techniques.

- Delivery: Ensure timely delivery and provide installation support if needed.

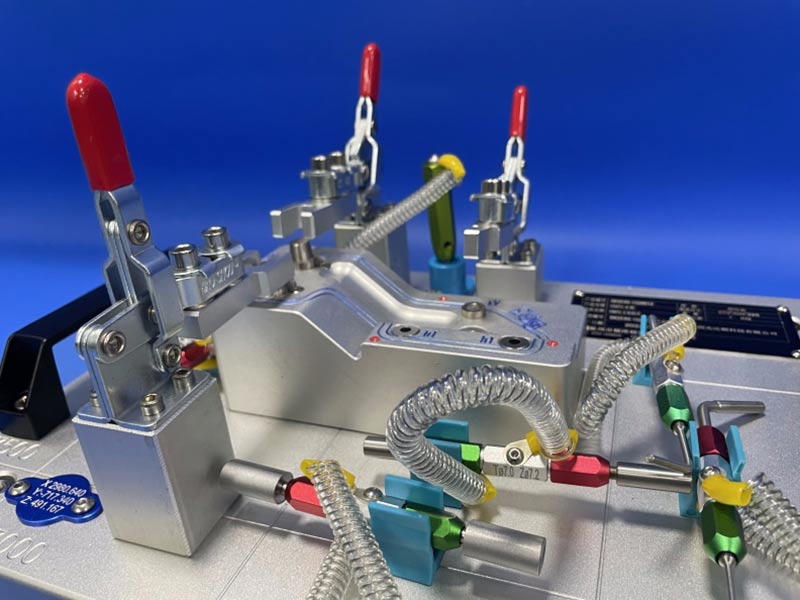

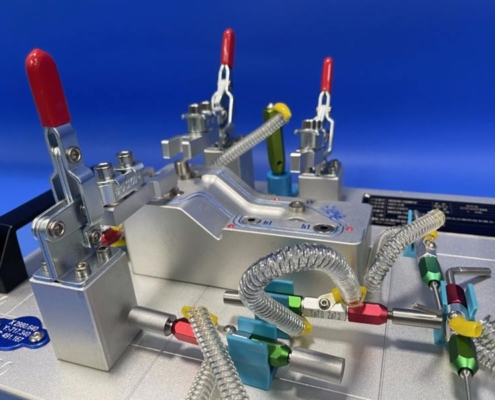

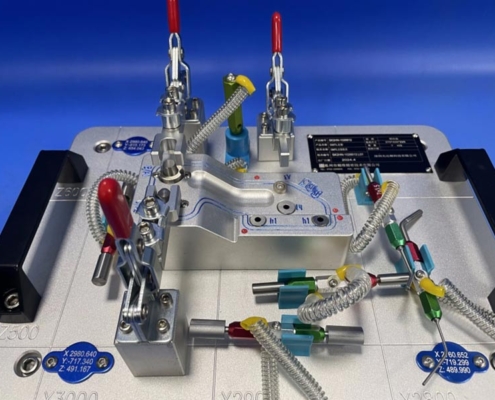

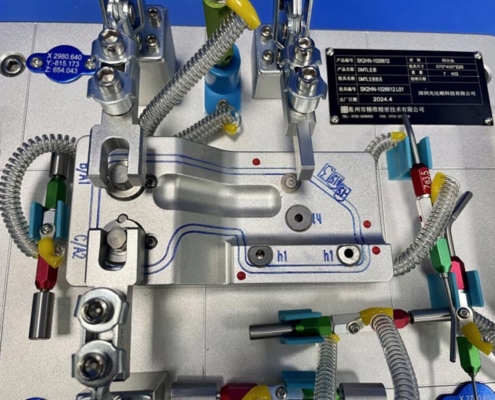

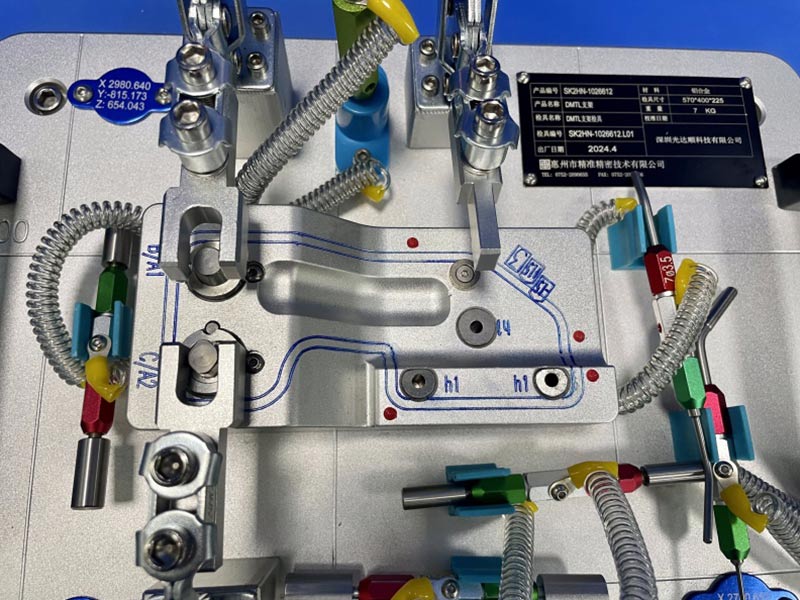

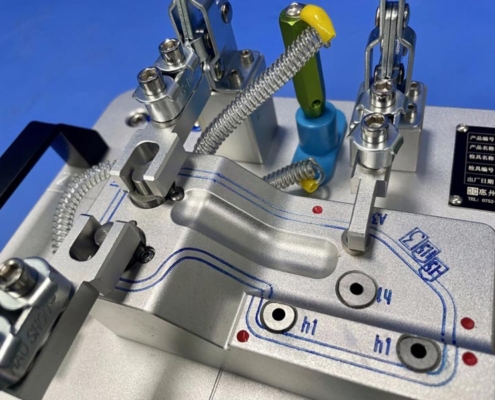

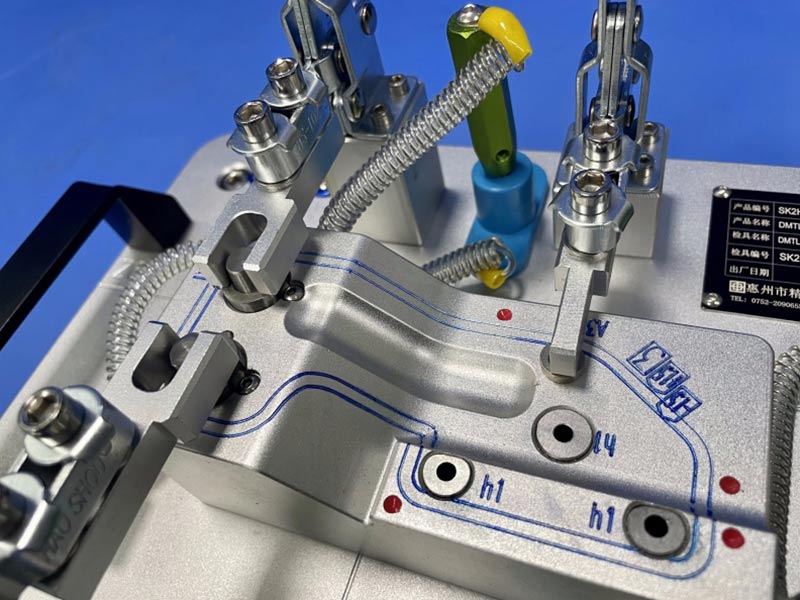

Assembly checking fixture for plastic panel of automotive

This assembly checking fixture set use cable retractors to control and clamp, and design the SPC ports as part of the flush/feeler rails as opposed to the simulation rail(s)

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF