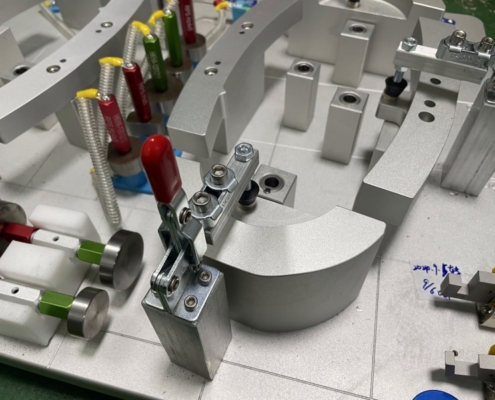

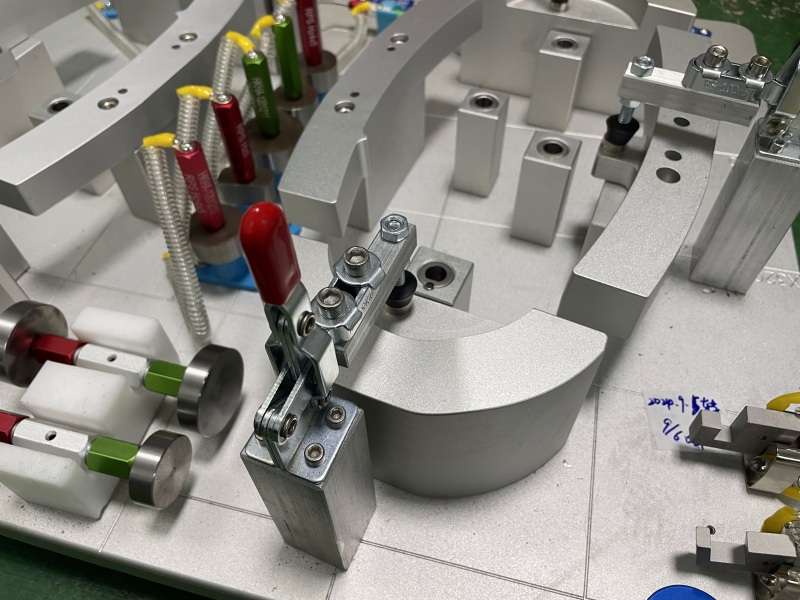

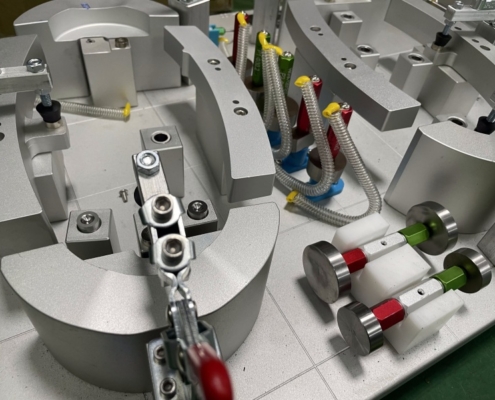

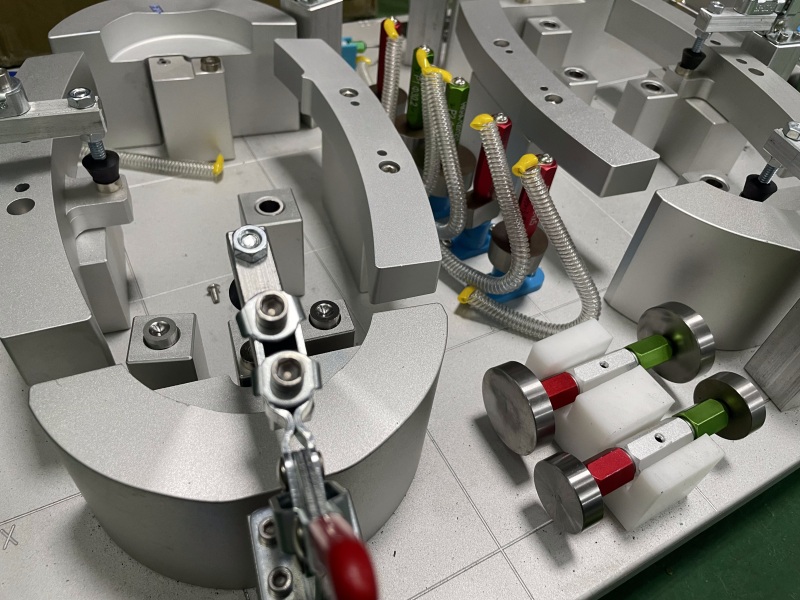

CMM Fixturing Inspection Tools are precision-engineered devices used to hold components securely during measurement with Coordinate Measuring Machines (CMMs). They ensure accurate positioning, enabling micron-level inspection for automotive, aerospace, and medical parts. Customizable designs optimize CMM efficiency and repeatability.

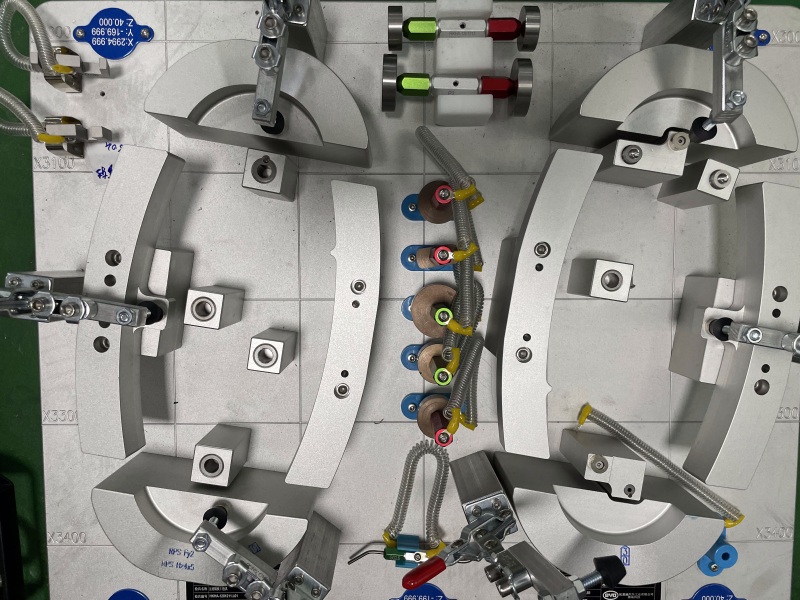

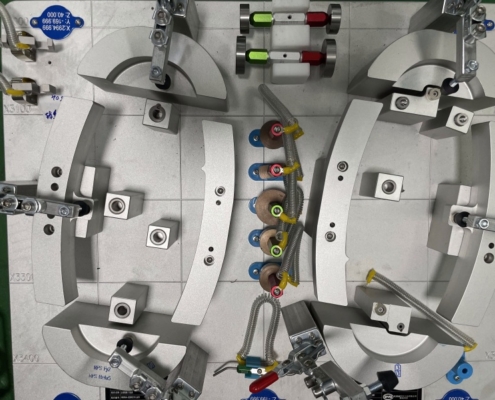

Precision CMM Fixturing Solutions for Automotive Inspection

Our CMM Fixturing inspection Tools can be categorized into three types based on the inspection object:

- Stamping Single-Part Checking Fixture

(For inspecting individual stamped components)

- Subassembly Checking Fixture

(For verifying assemblies composed of multiple parts)

- Modular Integrated Checking Fixture

(Designed for complex systems combining multiple subassemblies)

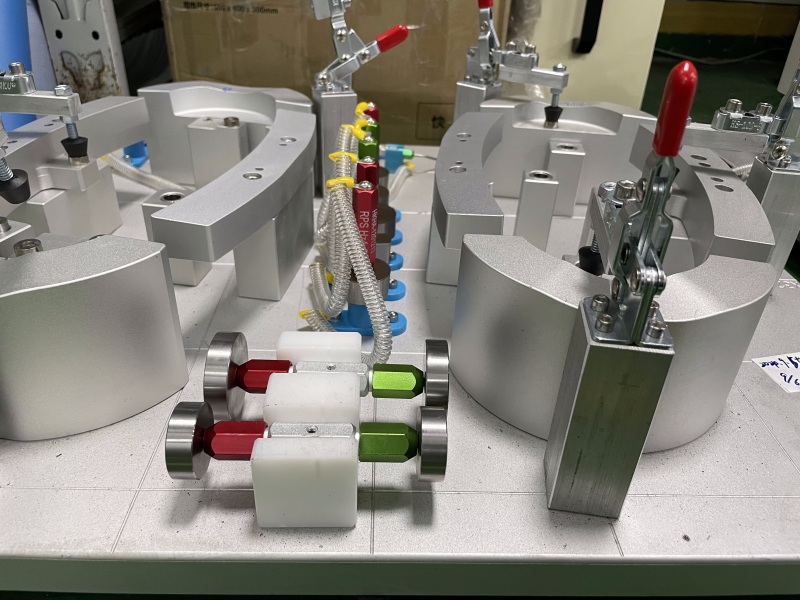

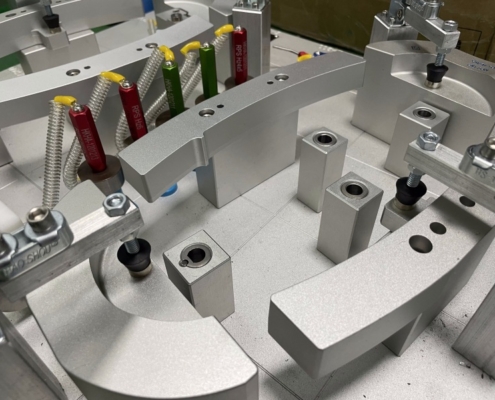

Key Features:

- First-article inspection fixtures

- Production batch sampling systems

- Functional testing of moving assemblies

- GD&T compliance verification (ASME Y14.5)

Technical Specifications:

- Measurement Accuracy: ±0.02mm repeatability

- Materials: Aircraft-grade aluminum (6061-T6) / Stainless steel options

- Modular Design: Reconfigurable for multiple part numbers

- Compatibility: Universal CMM machine adaptation (Zeiss, Mitutoyo, Hexagon)

- Surface Treatment: Anodized or powder-coated finishes

Industry-Specific Advantages

For Mold Manufacturers:

- Profile-checking fixtures with adjustable locators

- Cavity/core alignment verification tools

- Ejection pin position inspection systems

For Automotive Suppliers:

- Body-in-white measurement stations

- Powertrain component testing fixtures

- EV battery tray inspection solutions

Customization Process

- pload your 3D part data (STEP/IGES formats)

- Receive DFM analysis within 48 hours

- Approve fixture concept with FEA simulation

- Production delivery in 35-45 working days

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF