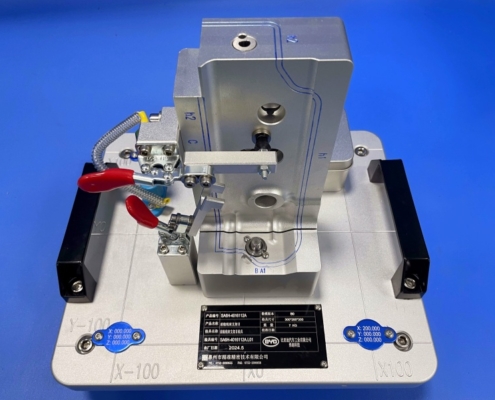

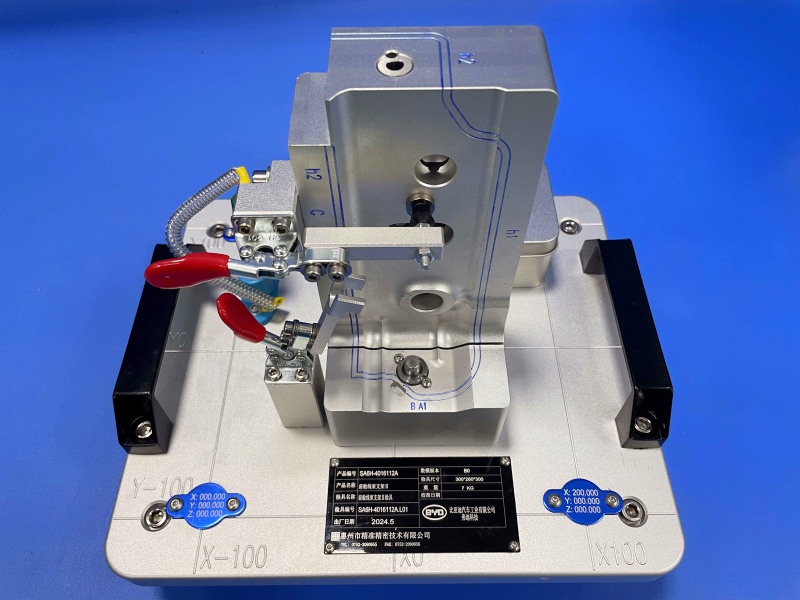

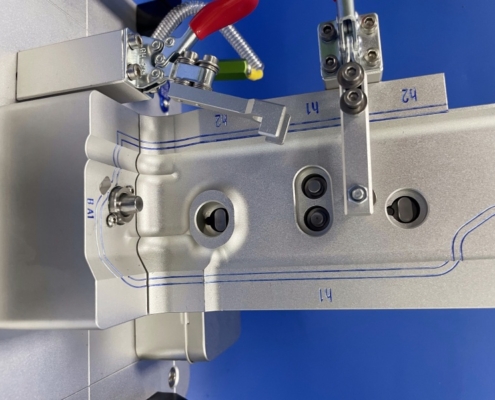

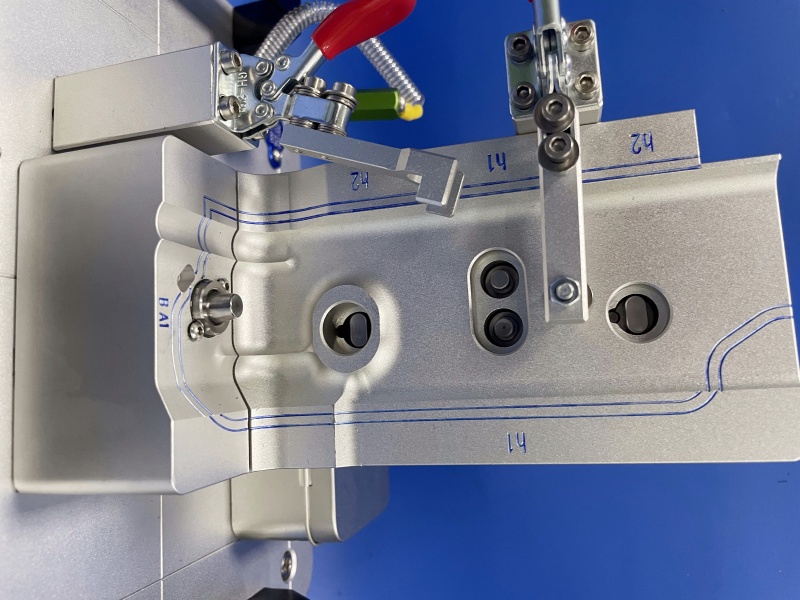

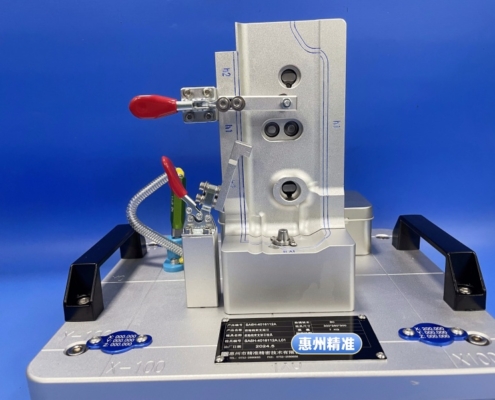

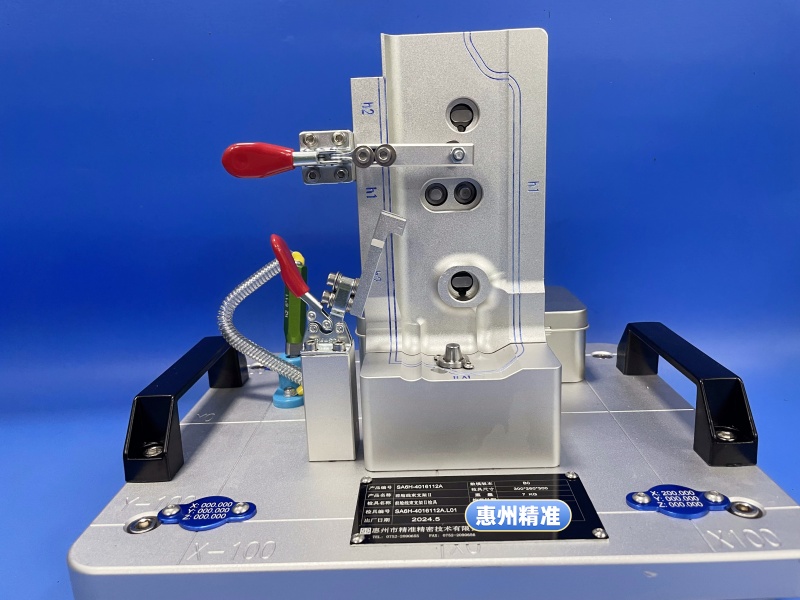

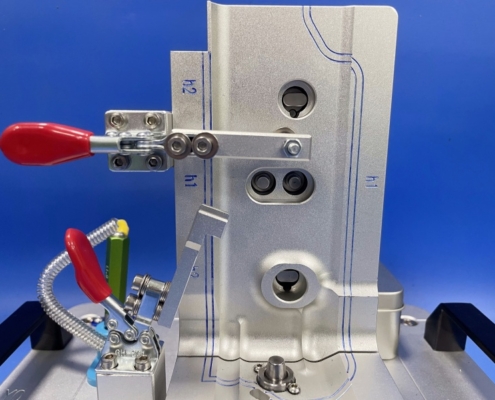

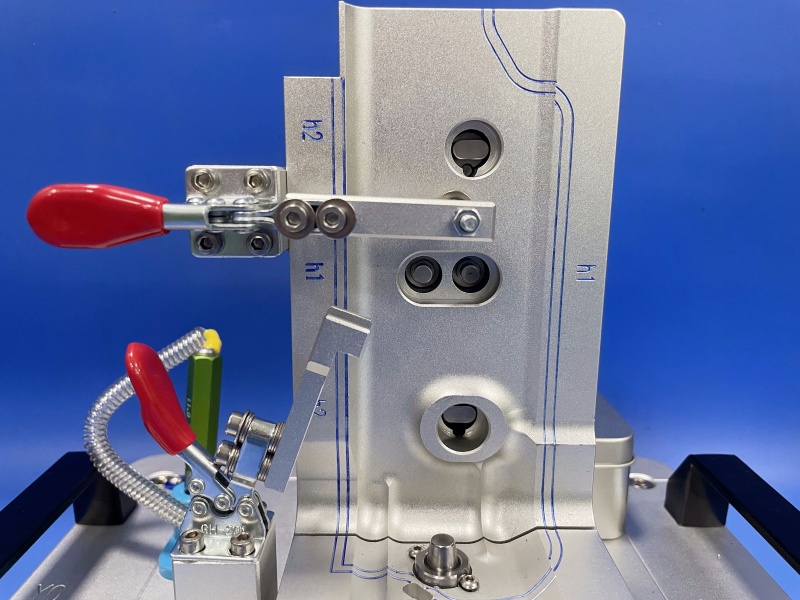

Our custom automotive inspection tools (checking fixtures/inspection fixtures) deliver unmatched precision for OEMs, Tier 1 suppliers, and assembly plants. Designed to validate car body panels, EV battery modules, powertrain components, and welded assemblies, these tools ensure ±0.02mm repeatability across production cycles.

Custom Automotive Inspection Tools – Precision Checking Fixtures & Quality Control Solutions

Ensure Flawless Automotive Parts with Our Custom Automotive Inspection Tools Engineered for precision, durability, and scalability, our custom automotive inspection tools are tailored to meet the rigorous demands of automotive manufacturers, mold makers, and assembly plants. From precision automotive fixtures to checking fixtures for complex components, we deliver scalable solutions that enhance quality control and reduce production errors.

Key Features:

✅ Modular Design – Adapt to multi-model production lines with quick-change components.

✅ Ergonomic Handling – Lightweight frames (<25kg) with anti-fatigue grips.

✅ Data-Driven QA – RFID tagging for traceability & IoT-ready sensor ports.

✅ Corrosion Resistance – Anodized coatings for humid/chemical environments.

Technical Specifications:

| Parameter | Detail |

|---|---|

| Materials | Aerospace-grade aluminum (6061-T6), Stainless steel (304/316), Carbon fiber composites |

| Tolerance | ±0.05mm (standard), ±0.02mm (high-precision option) |

| Compatibility | CMM (Zeiss/Mitutoyo), 3D scanners (FARO/GOM), OEM protocols (Ford/GM/VW) |

| Certifications | ISO 9001:2015, IATF 16949, GD&T ASME Y14.5-2018 |

| Lead Time | 4-6 weeks (design to delivery) |

| Customization | CAD/CAM integration (SolidWorks, CATIA), Rapid prototyping support |

Applications in Automotive Manufacturing

Body-in-White (BIW) Inspection – Validate door hinges, roof panels, and chassis alignment.

EV Battery Assembly – Ensure thermal pad contact accuracy and cooling system sealing.

Powertrain Testing – Check gearbox housing parallelism and shaft concentricity.

Final Assembly QA – Verify dashboard fitment and ADAS sensor positioning.

How to Order

- Submit Your Requirements – Share CAD drawings, tolerance specs, and application details.

- Custom Design Review – Our team confirms feasibility within 48 hours.

- Production & Testing – Rigorous QA checks before shipment.

- On-Site Support – Training and calibration services included.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF