Ensure flawless quality control for critical dimensions, positional accuracy, and functional performance with bespoke inspection fixtures engineered for your exact specifications. Designed for manufacturers of high-tolerance molds, automotive components, aerospace parts, and medical devices.

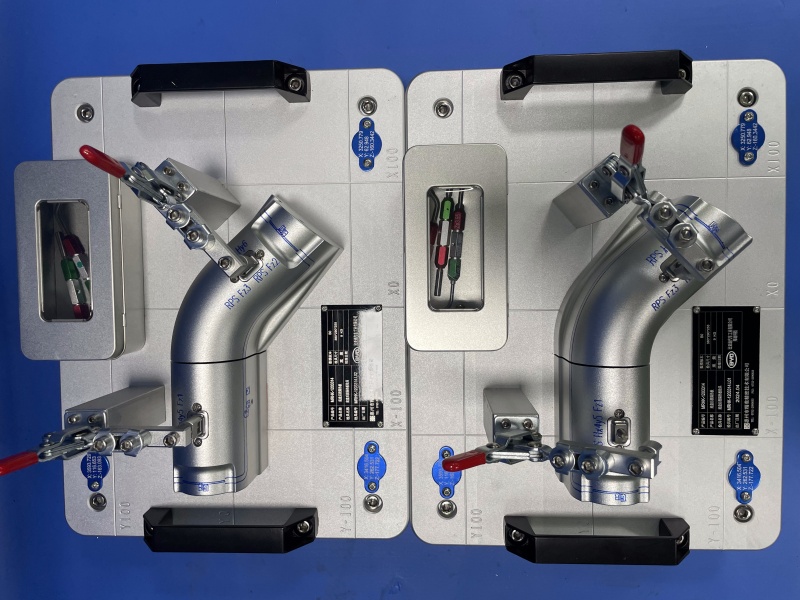

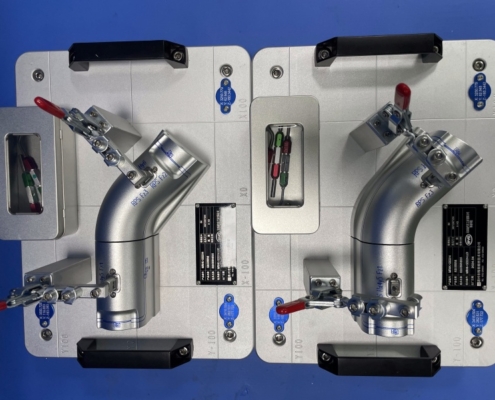

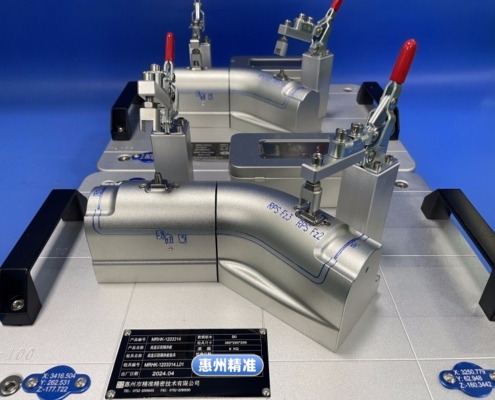

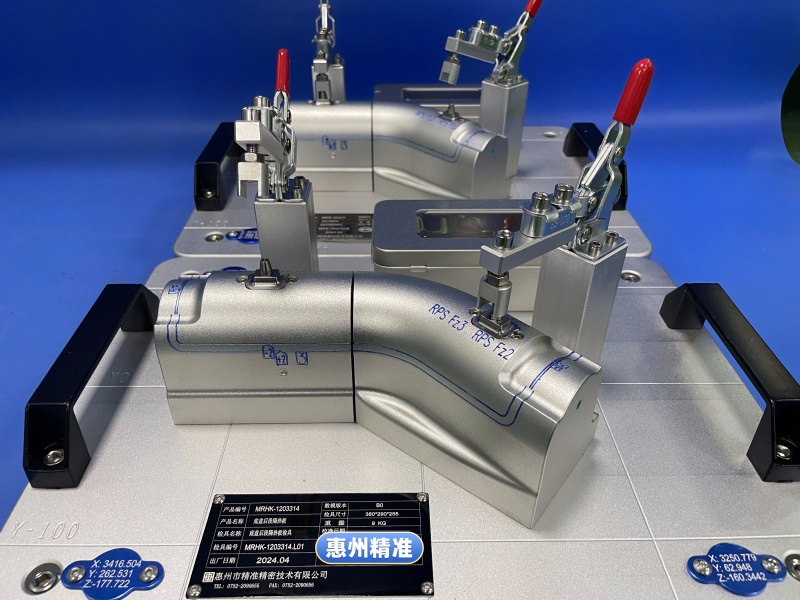

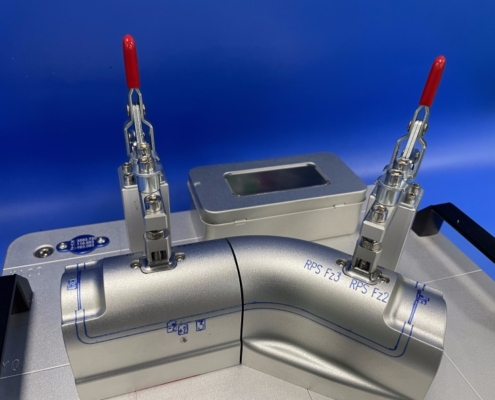

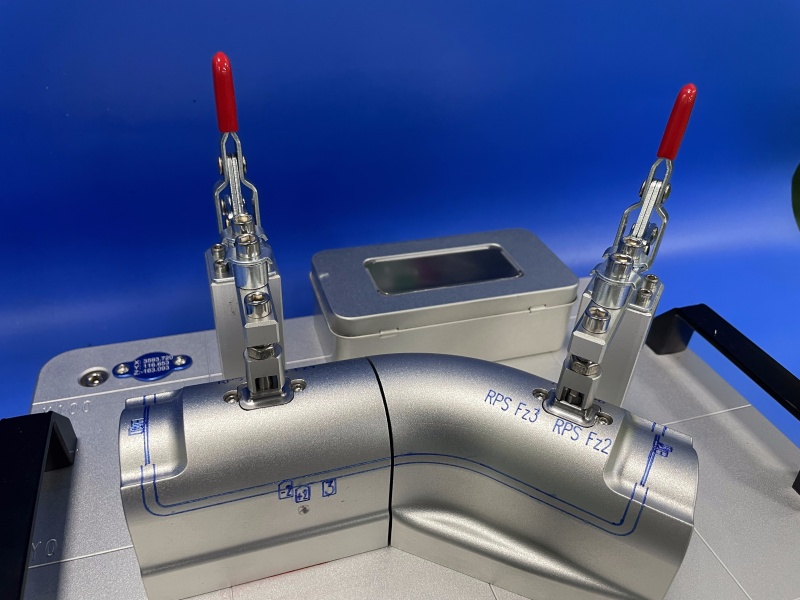

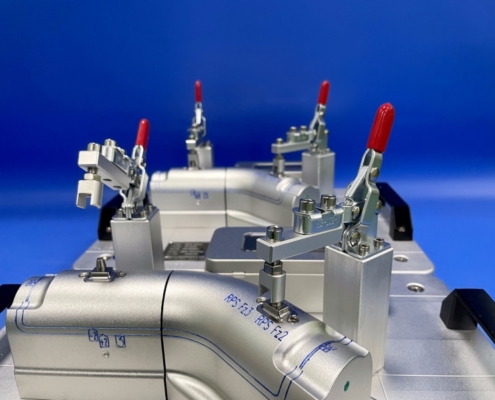

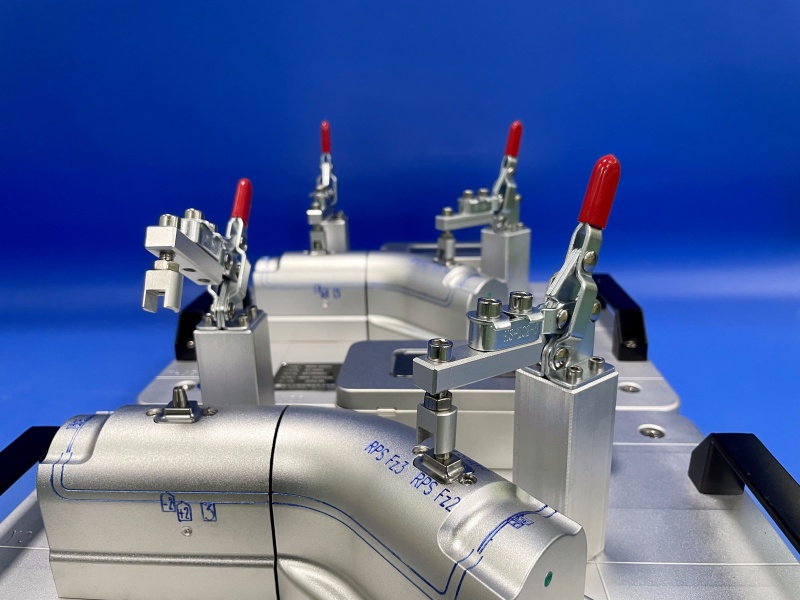

Customized Inspection Fixtures for Precision Components & Molds

Key Features

-

Precision-Driven Design

-

Validate dimensions, geometric tolerances (GD&T), and functional fits with ±0.001″ (0.025mm) repeatability.

-

Hardened tooling-grade steel or anodized aluminum frames for stability in high-volume production.

-

-

Tailored to Your Part

-

Fully customized fixtures with 3D CAD-based simulations of datums, clamps, and functional gauges.

-

Optimized for complex features: bore concentricity, surface profiles, hole patterns, and assembly interfaces.

-

-

GD&T & Industry Compliance

-

ASME Y14.5-compliant datum references and tolerance validations.

-

Compatible with CMMs, optical scanners, and handheld measurement tools (e.g., height gauges, micrometers).

-

-

Modular & Future-Proof

-

Interchangeable components (locators, clamps, probes) for easy adaptation to design revisions.

-

Reduce requalification costs by 40% with scalable, upgradeable systems.

-

-

Durable & Reliable

-

Powder-coated or anodized finishes resist corrosion, coolant, and temperature fluctuations (-20°C to 60°C).

-

Maintenance-free operation for 50,000+ inspection cycles.

-

Key Features:

- Versatile Applications: Suitable for checking single metal parts, aluminum casting parts, and plastic components.

- High Precision: Designed for processing precision, ensuring that every measurement is accurate.

- Durability: Constructed from high-quality materials to withstand rigorous use and ensure longevity.

- Ease of Use: User-friendly design simplifies the checking process, reducing setup time and increasing efficiency.

Technical Specifications:

- Processing Precision: Ensures high-level accuracy during the checking process.

- Accuracy for Other Profiles: Ideal for single stamping, assembly, and casting checking fixtures.

- Datum Hole Accuracy: +/- 0.05mm, ensuring precise measurements for critical dimensions.

- Material: Made from top-grade materials to ensure reliability and durability.

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF