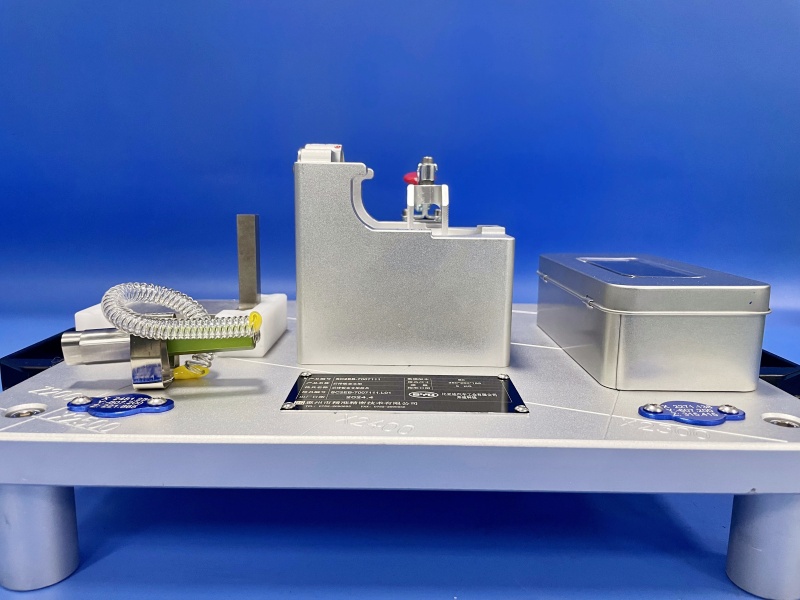

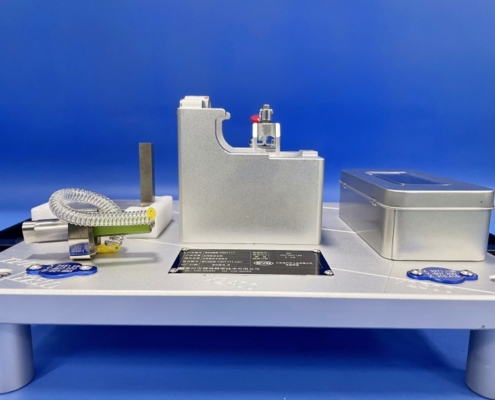

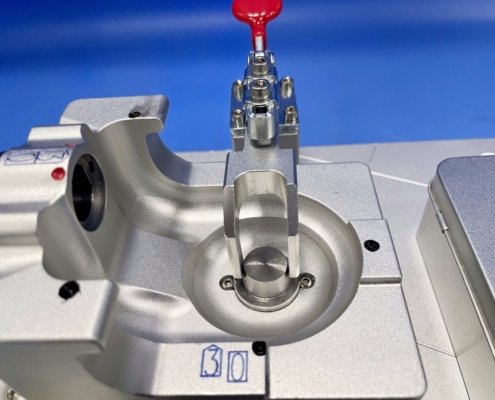

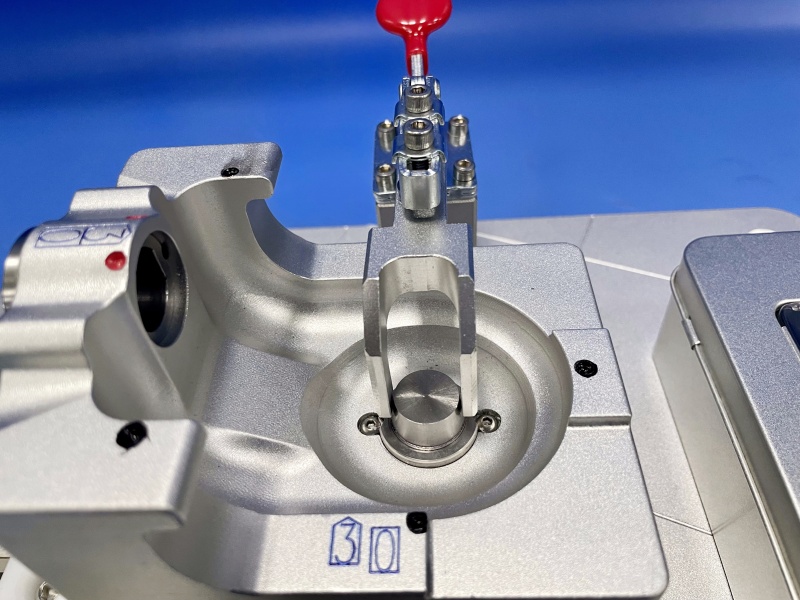

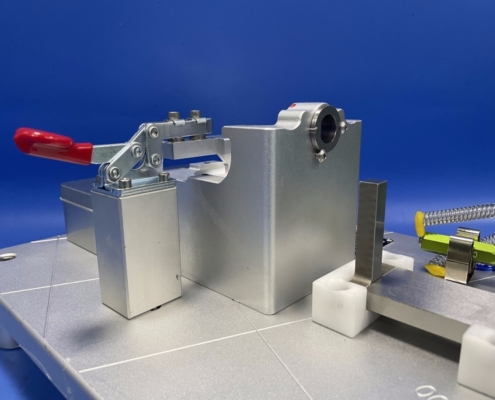

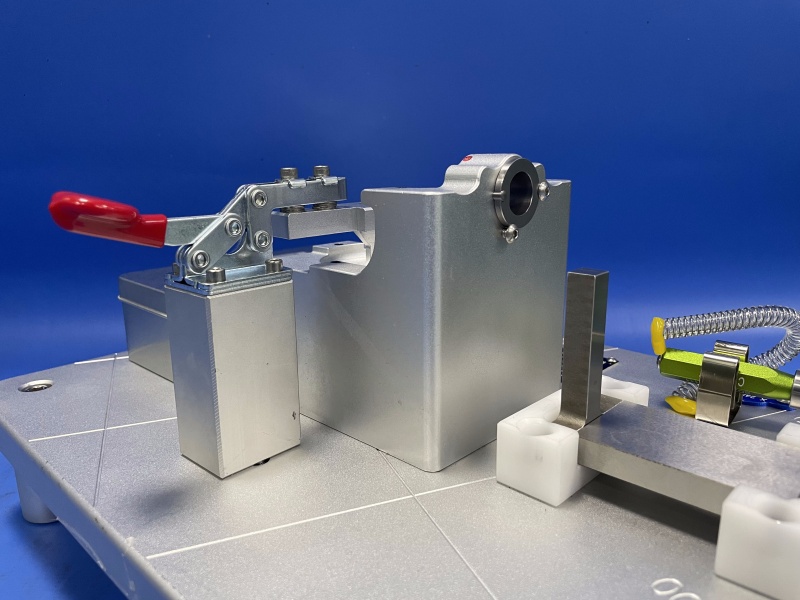

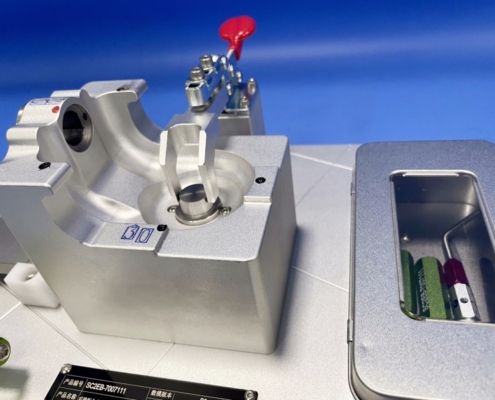

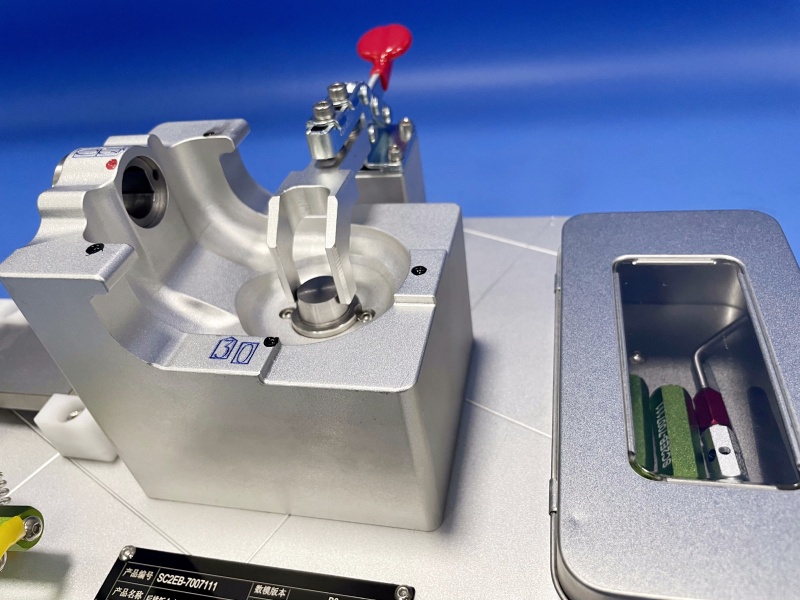

A Fixture Testing Tool is a specialized device used to validate the precision, alignment, and functionality of inspection fixtures in manufacturing. It ensures quality control through automated measurements, data analysis, and compliance verification.

Inspection welding fixture testing automotive checking gauges factory

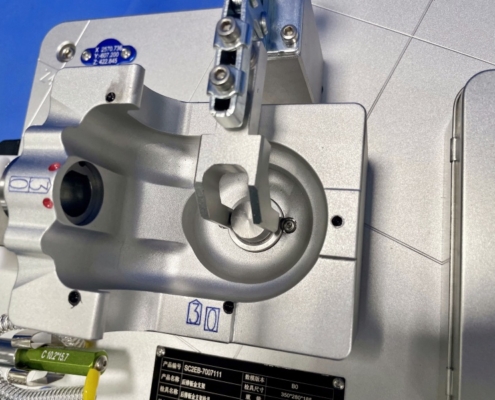

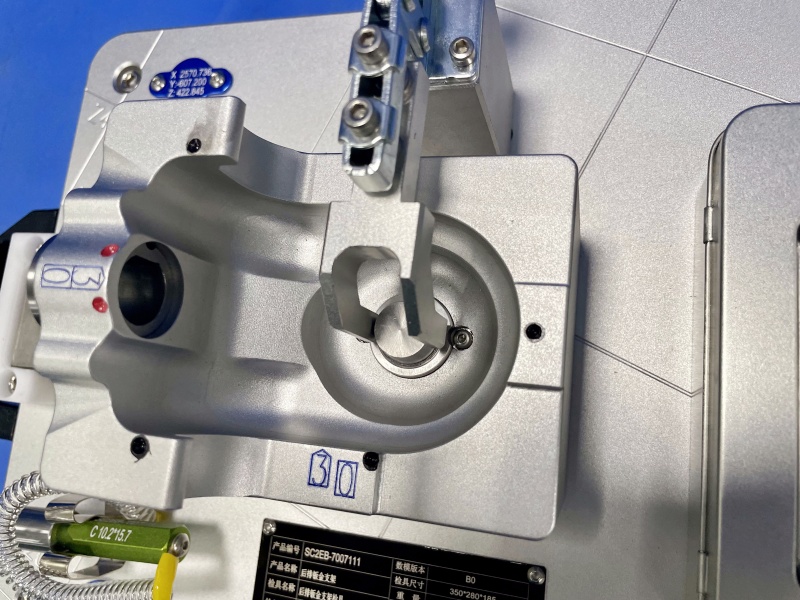

- 3D Laser Scanning Technology: Captures micron-level deviations in fixture geometry, ensuring ISO/GD&T compliance.

- Automated Alignment Verification: Validates critical dimensions, angularity, and positional accuracy in seconds.

- Real-Time Data Analytics: Generates AI-powered reports with trend analysis and failure mode predictions.

- Modular Design: Adapts to fixtures of any size (50mm–2000mm) with quick-swap tooling kits.

- Cloud-Connected Platform: Enables remote monitoring, audit trails, and cross-facility standardization.

key feature

- Versatile Applications: Suitable for checking single metal parts, aluminum casting parts, and plastic components.

- High Precision: Designed for processing precision, ensuring that every measurement is accurate.

- Durability: Constructed from high-quality materials to withstand rigorous use and ensure longevity.

- Ease of Use: User-friendly design simplifies the checking process, reducing setup time and increasing efficiency.

Technical Specifications:

- Processing Precision: Ensures high-level accuracy during the checking process.

- Accuracy for Other Profiles: Ideal for single stamping, assembly, and casting checking fixtures.

- Datum Hole Accuracy: +/- 0.05mm, ensuring precise measurements for critical dimensions.

- Material: Made from top-grade materials to ensure reliability and durability.

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF