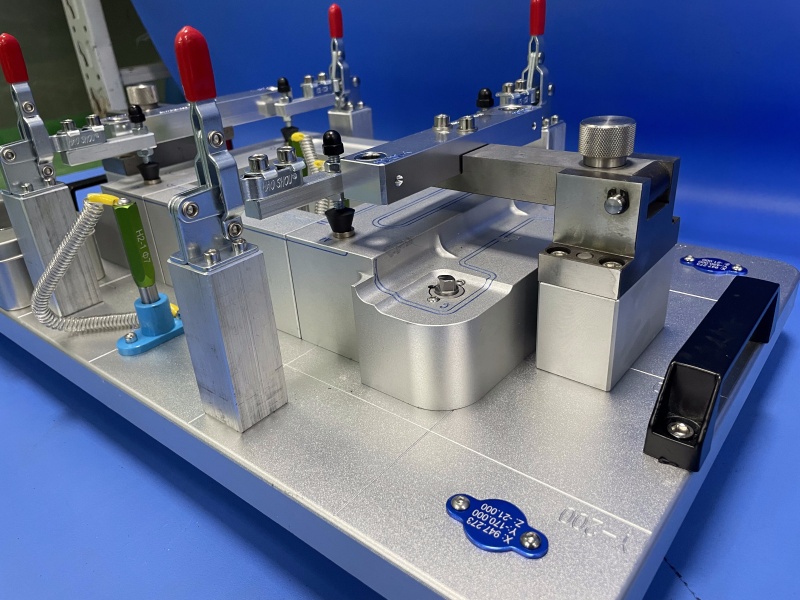

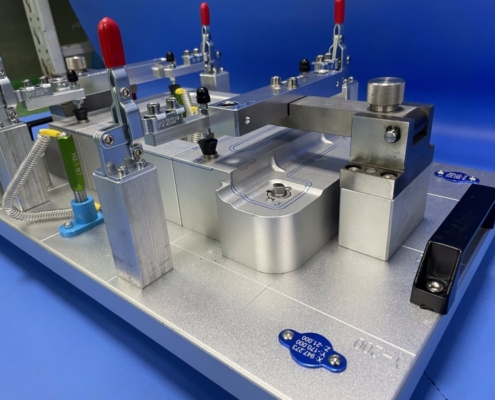

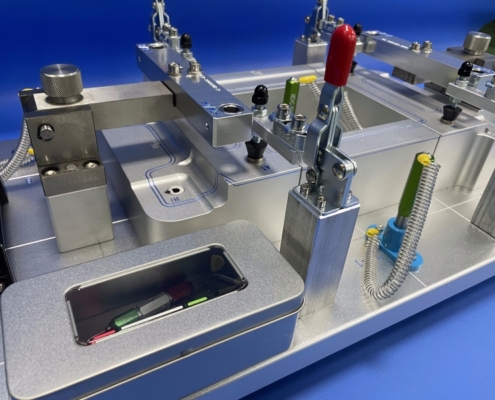

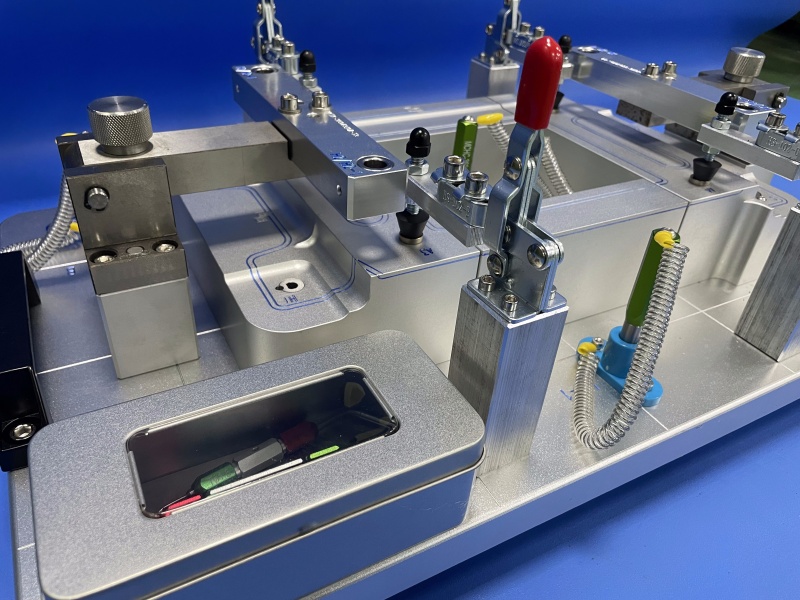

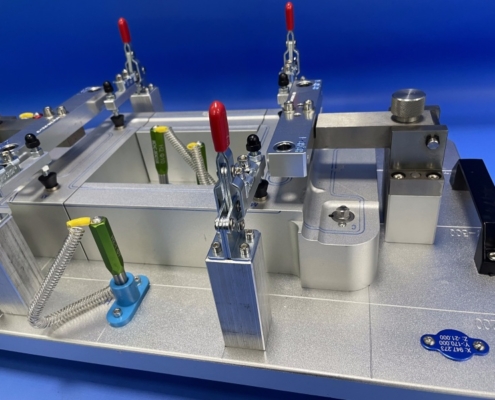

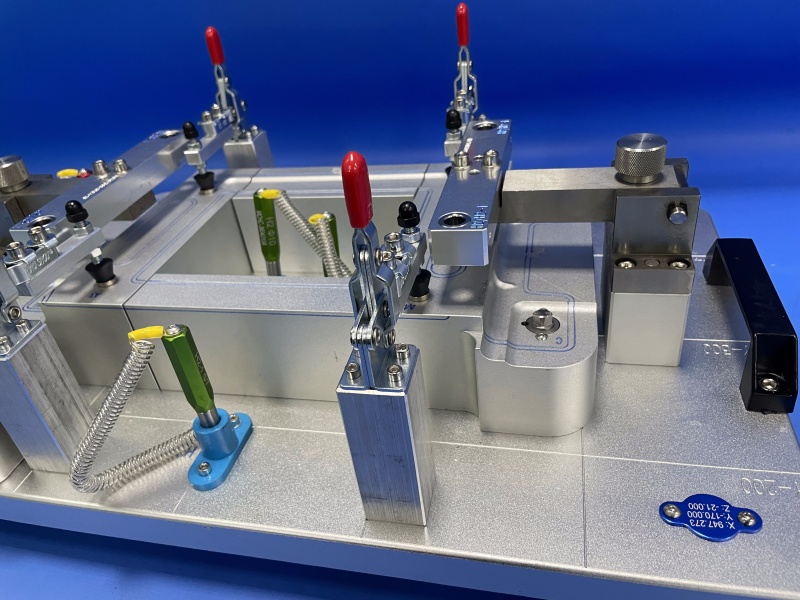

Our ISO 9001-certified go no go gauges and custom checking fixtures are engineered for critical dimensional validation in automotive assembly processes. Designed to meet IATF 16949 standards, these precision inspection fixtures deliver ±0.005mm repeatability for components ranging from EV battery trays to transmission housings.

Product Description: Precision Go No Go Gauge & Custom Inspection Fixtures for Industrial Quality Control

Simplify dimensional verification with our custom Go No Go Gauge and precision inspection fixtures, engineered for automotive, mold, and die-casting industries. Designed to meet stringent ISO standards, our solutions ensure ±0.005mm accuracy for rapid part validation, reducing production errors by up to 40%.

Key Features:

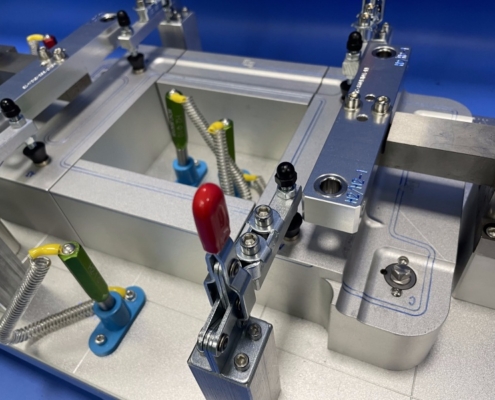

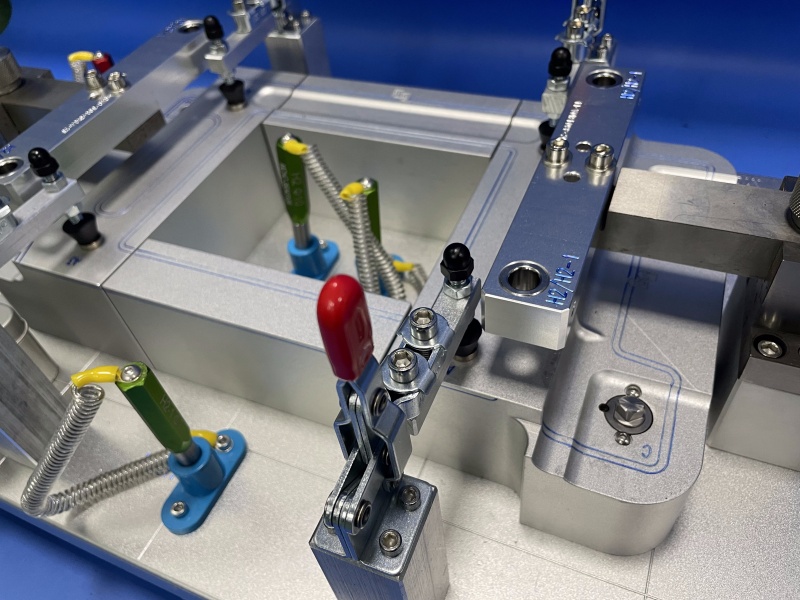

Off-the-shelf go/no go gauges work for simple dimensions, but complex parts demand tailored solutions. Our fixtures integrate multiple inspection points into a single tool, streamlining workflows and reducing human error.

Key Features:

🔧 Non-Standard Design: CAD/CAM-integrated fixtures for unique geometries.

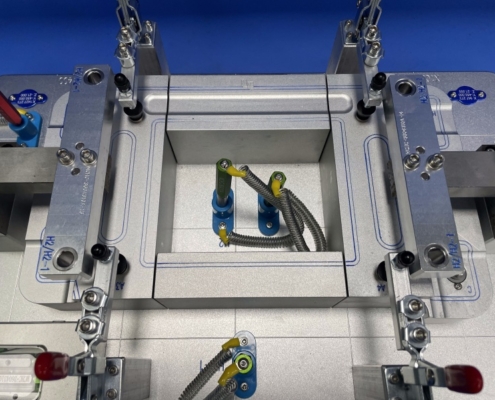

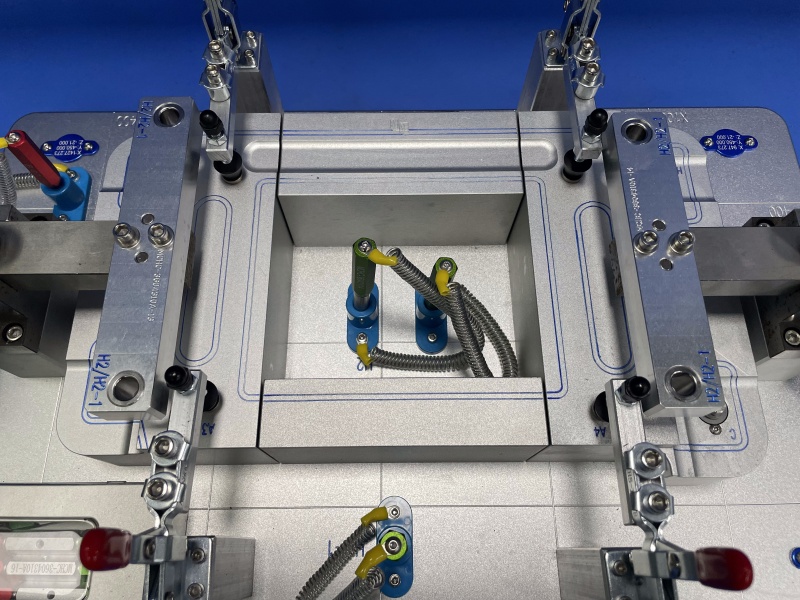

📏 CMM Compatibility: Seamless integration with coordinate measuring machines.

🔒 FAI Compliance: First Article Inspection documentation included.

⚙️ Modular Components: Swapable inserts for varying part configurations.

Key Technical Specifications

| Feature | Specification | Industry Application |

|---|---|---|

| Measurement Range | 50mm – 2500mm | Body-in-White Assembly |

| Material Grade | 6061-T6 Aluminum/Stainless Steel | Powertrain Components |

| Temperature Stability | ±0.002mm/℃ | EV Battery Module |

| GD&T Compliance | ASME Y14.5-2018 Standard | Suspension Systems |

Applications & Industries

- Automotive: Validate die-casting parts, transmission components, and engine blocks.

- Mold Manufacturing: Ensure consistent cavity dimensions for plastic injection molding.

- Aerospace: Verify tight-tolerance aerospace parts with our aerospace-grade fixtures.

Why Choose Our Go No Go Fixtures?

1. Modular Design for Fast Reconfiguration

- Adapt to engineering changes within 48 hours with our patented quick-change fixture system, reducing downtime during product iterations.

2. CMM-Compatible Base Structure

- Pre-machined M6/M8 threaded mounting grids enable seamless integration with Zeiss/Mitutoyo CMM systems.

3. PPAP Documentation

- Support Receive complete PSW/ISIR packages with every fixture, including GR&R reports and CMK analysis data.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF