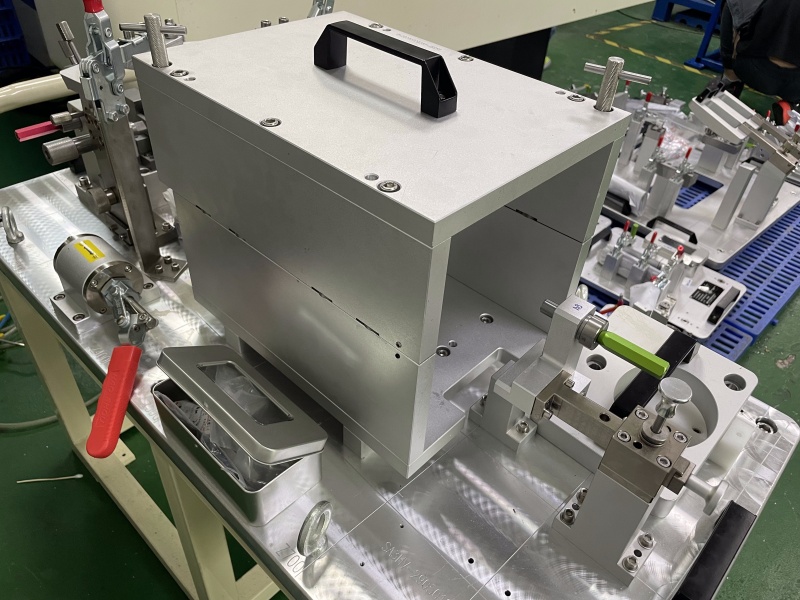

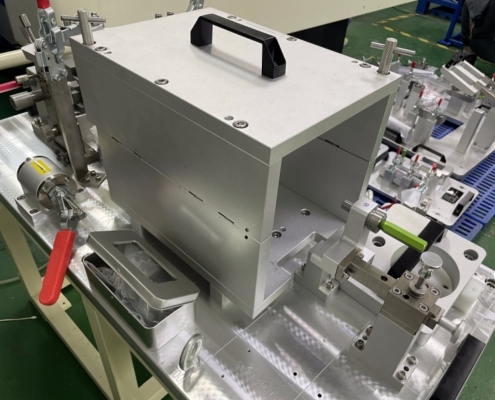

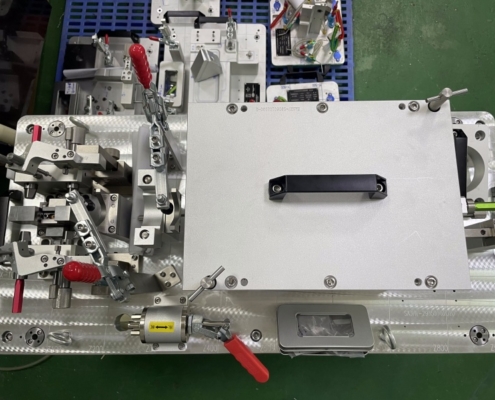

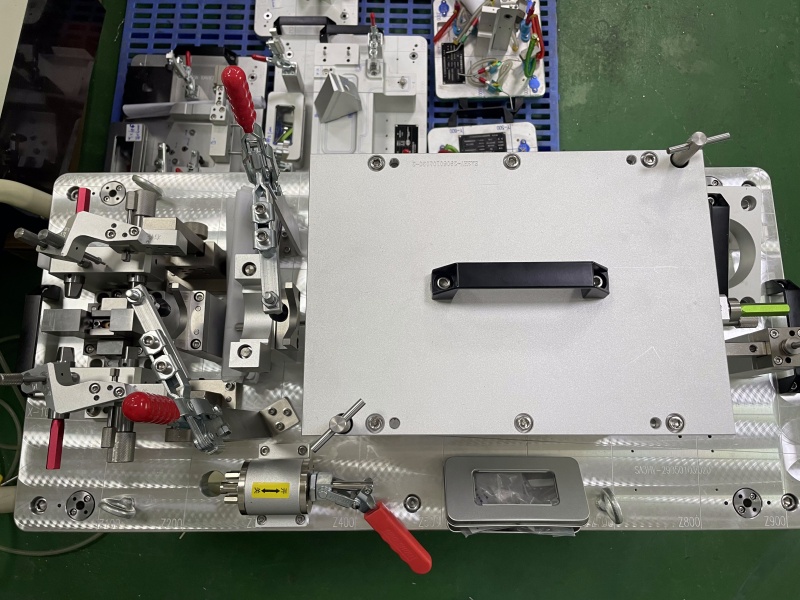

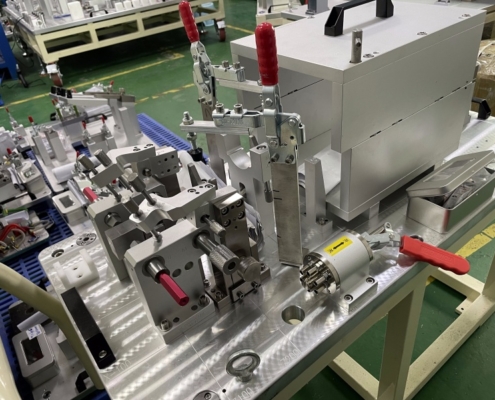

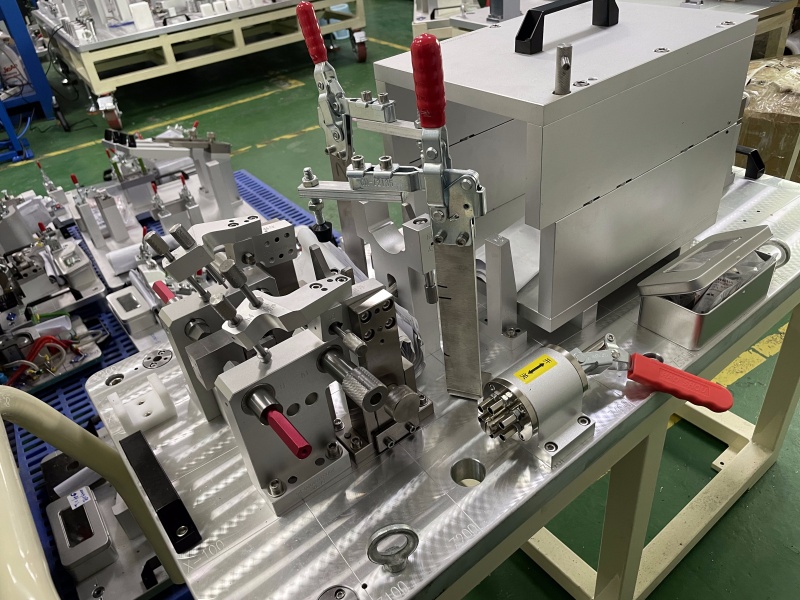

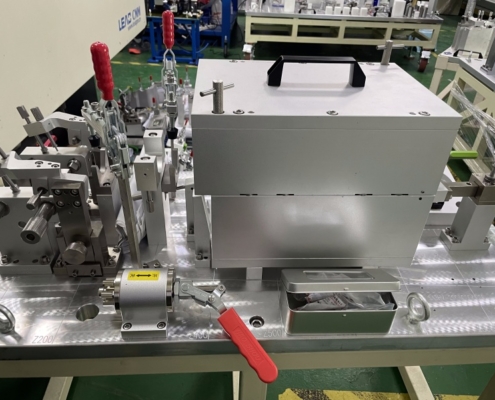

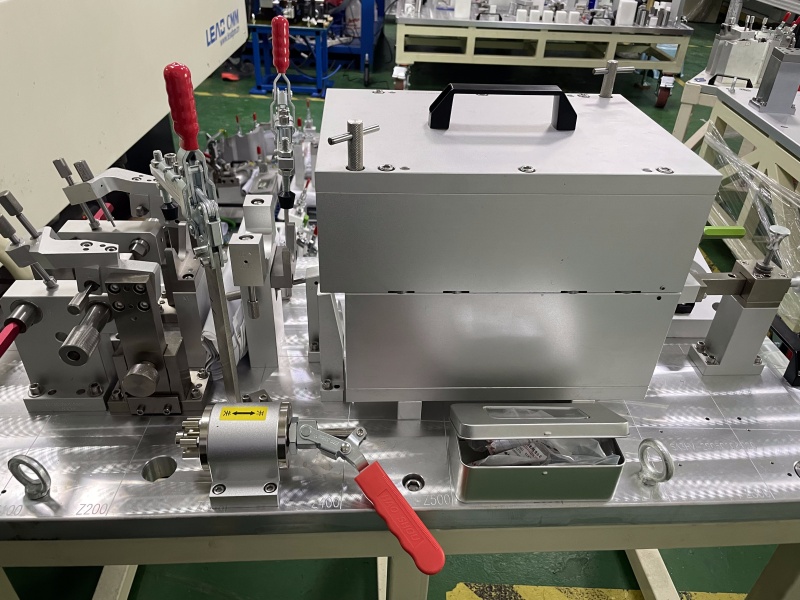

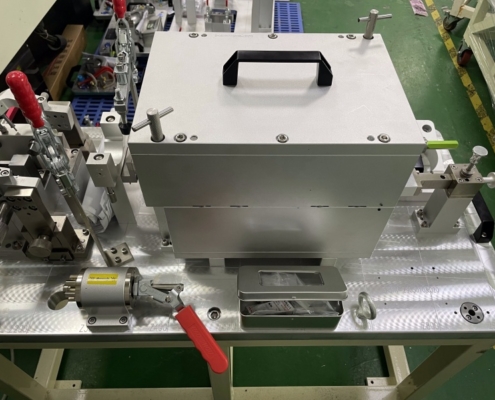

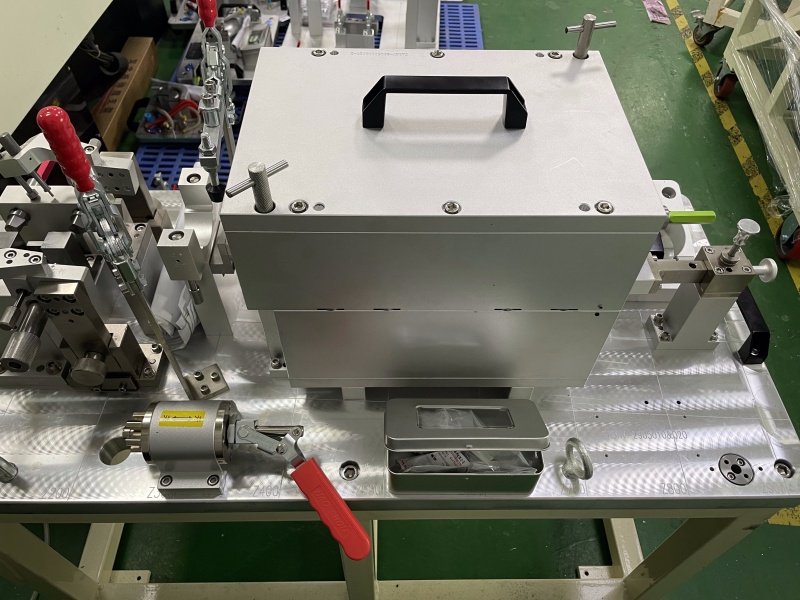

An Inspection Jig is a precision-engineered tool designed to verify dimensional accuracy, shape, and alignment of components in manufacturing. Customizable for automotive, aerospace, and precision industries, it ensures quality control through repeatable measurements. Our CNC-machined jigs integrate modular designs and robotic compatibility, enabling ISO-compliant verification of critical parts like molds, automotive assemblies, and high-tolerance components, reducing defects and streamlining production workflows.

Precision Inspection Jigs & Custom Checking Fixtures

Designed for mold makers and precision component manufacturers, these custom fixtures validate:

- Part-to-CAD deviation analysis

- Assembly interface positioning

- Production part approval (PPAP) documentation

Key Features:

✔ Modular Design: Interchangeable probes and adjustable locators for multi-part inspection

✔ Durable Construction: Hardened tool steel or aircraft-grade aluminum options

✔ Smart Integration: QR code tracking and SPC data export capabilities

✔ Industry-Specific: Configurations for automotive stampings, medical devices, and aerospace components

Technical Specifications:

- Measurement Range: 0.1-1500mm

- Temperature Compensation: 18-22°C operating range

- Surface Protection: Non-marring nylon or PEEK contact points

- Compliance: ASME Y14.5-2018 standards

Customization Process

- Upload your 3D part file or CAD model

- Receive DFM analysis within 48 hours

- Approve jig prototype design

- Production delivery in 15-30 working days

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF