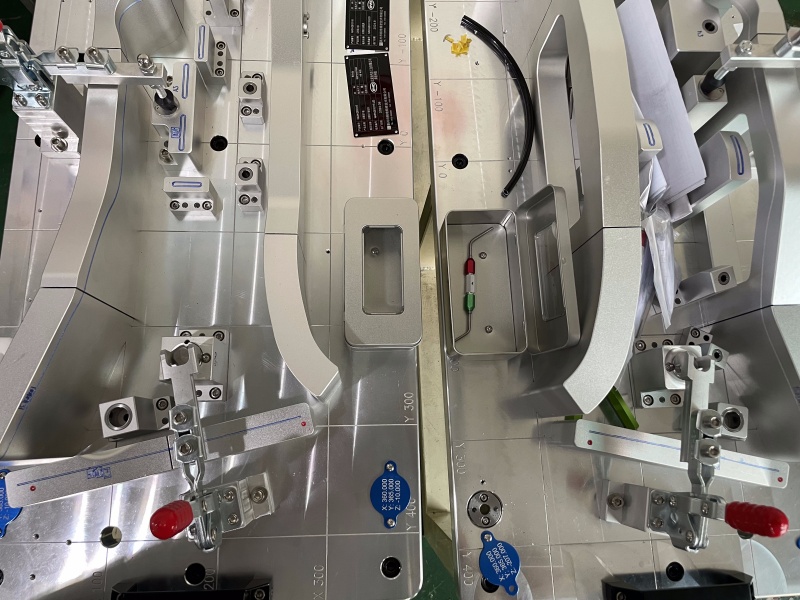

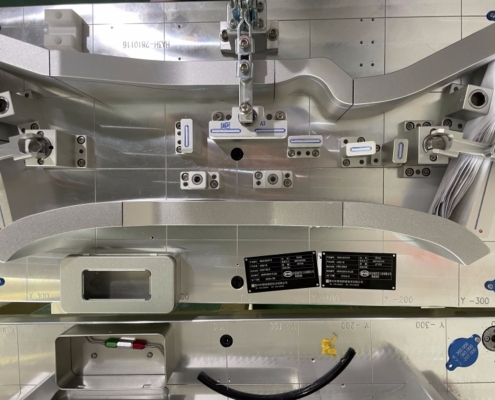

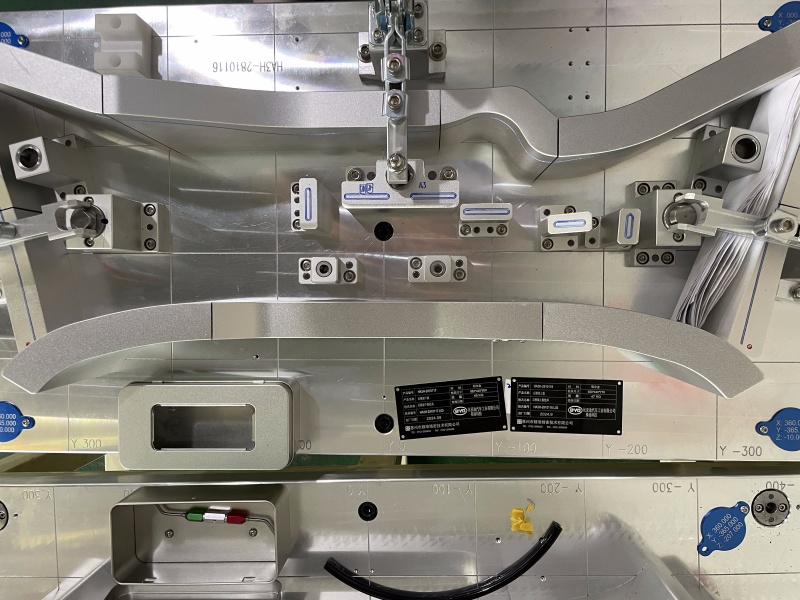

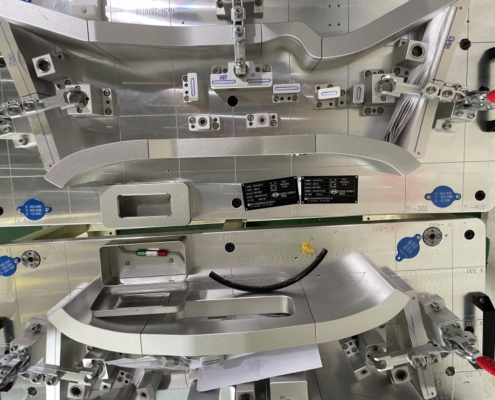

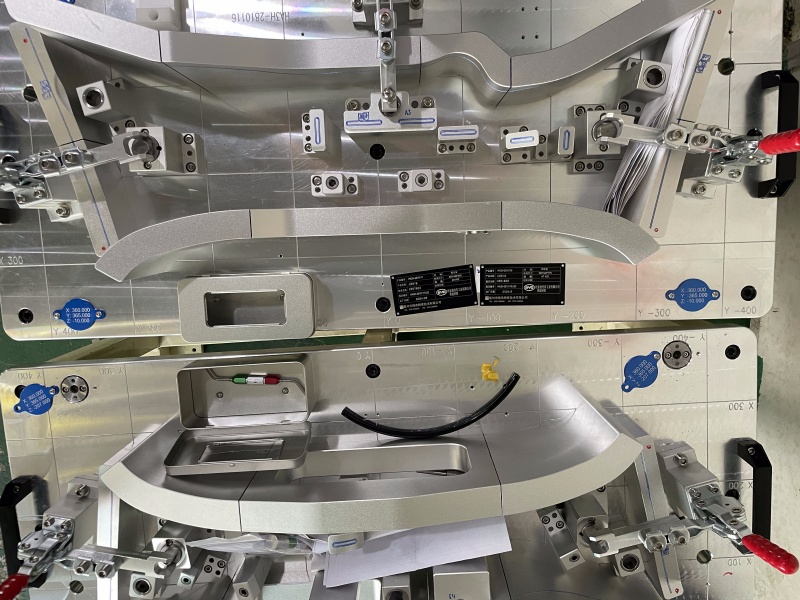

Jig Checking Fixtures are specialized tooling devices used to accurately inspect and verify the dimensions, alignment, and functionality of manufactured parts, ensuring quality control in precision industries like automotive and aerospace

Modular Jig Fixture Systems for Complex Components

Our Jig Checking Fixture is a versatile and high-precision tool designed for a variety of checking needs, including:

- Single Metal Parts Checking Fixtures

- Casting Aluminium Parts Checking Fixtures

- Plastic Checking Fixtures

Core Features of Our Jig Checking Fixtures

- Micron-Level Precision: Built with hardened steel and aerospace-grade aluminum, our fixtures achieve ±0.005mm repeatability for CMM-grade validation.

- Modular Design: Interchangeable inserts and adjustable locators adapt to multiple part variants, reducing setup time by 40%.

- Smart Integration: Compatible with SPC software and automated data logging for seamless traceability.

- Ergonomic Interface: Color-coded pass/fail indicators and intuitive clamping mechanisms minimize operator error.

Technical Specifications:

- Calibration: Every fixture undergoes rigorous certification to ensure compliance with global quality standards.

- Rapid Prototyping: Turnkey solutions delivered in 10–15 business days via in-house CNC machining and 3D printing.

- Material Flexibility: Validate parts made from titanium, Inconel, PEEK, and other exotic materials without distortion.

Applications & Use Cases

- Mold Validation: Verify injection mold tooling alignment before first-shot production.

- Aerospace Fasteners: Inspect thread pitch, head height, and drive compatibility for engine components.

- Medical Devices: Validate lumen dimensions, biocompatibility coatings, and sterilization tray fit.

- Automotive Gearboxes: Check gear tooth mesh, bearing journal concentricity, and sealant groove depth.

Customization Options

Every fixture is tailored to your workflow:

- CAD Integration: Upload your STEP/IGES files for design-specific tooling.

- Climate Testing: Add thermal chambers to simulate extreme operating conditions.

- Robotic Compatibility: Integrate with collaborative robots (Cobots) for lights-out validation.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF