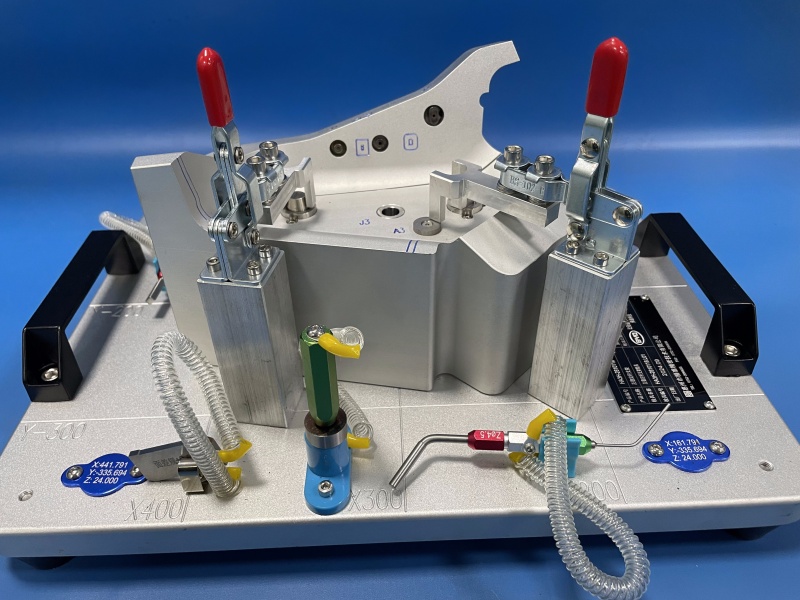

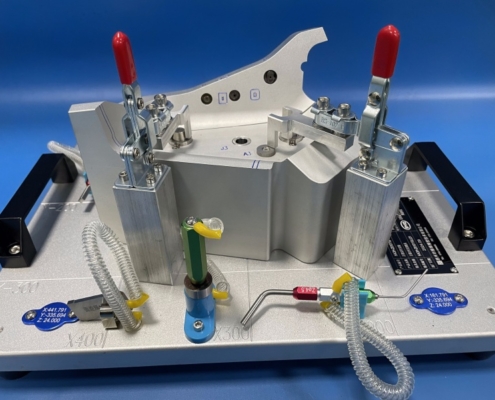

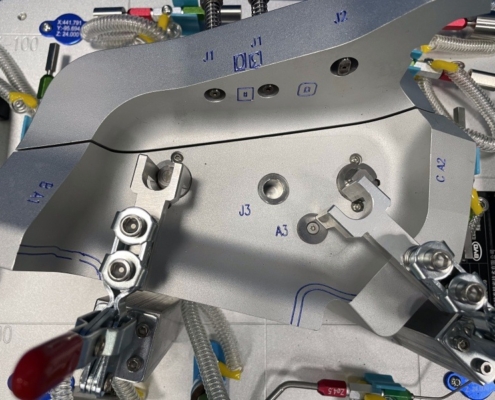

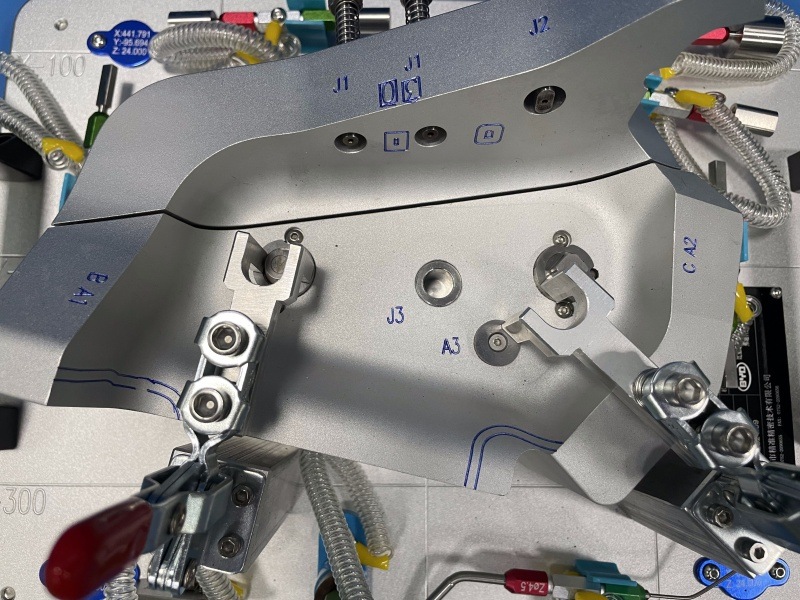

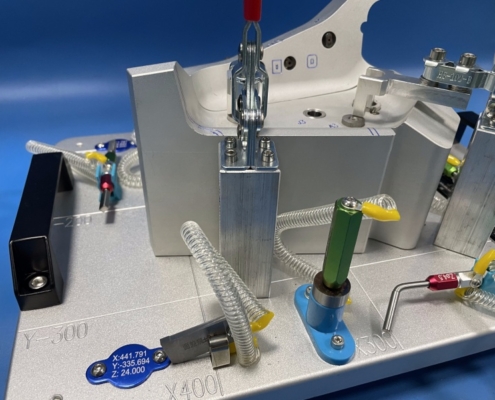

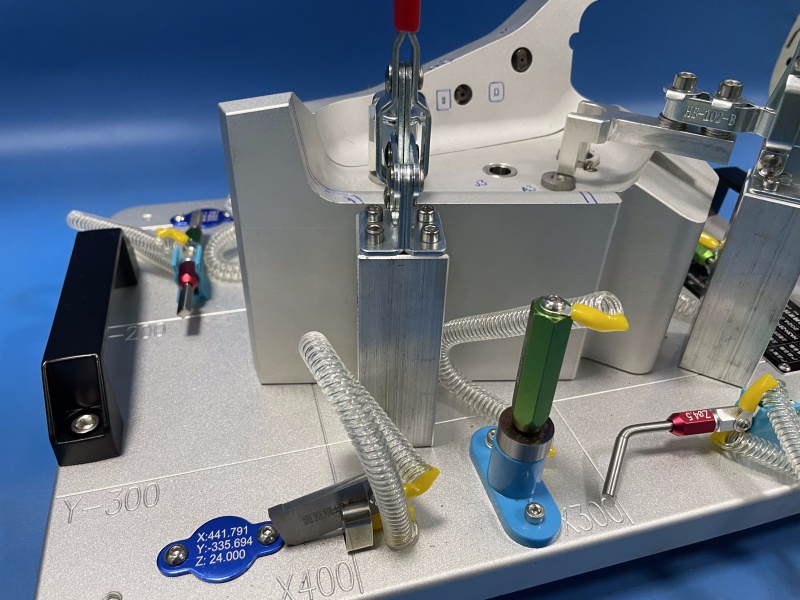

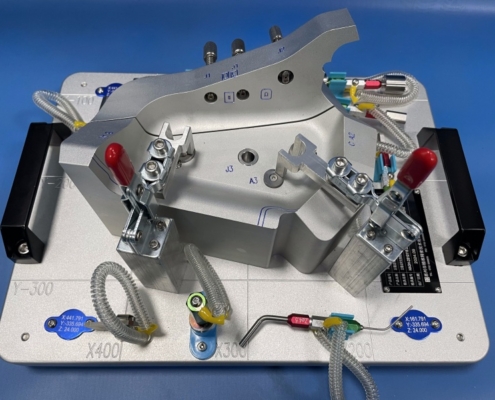

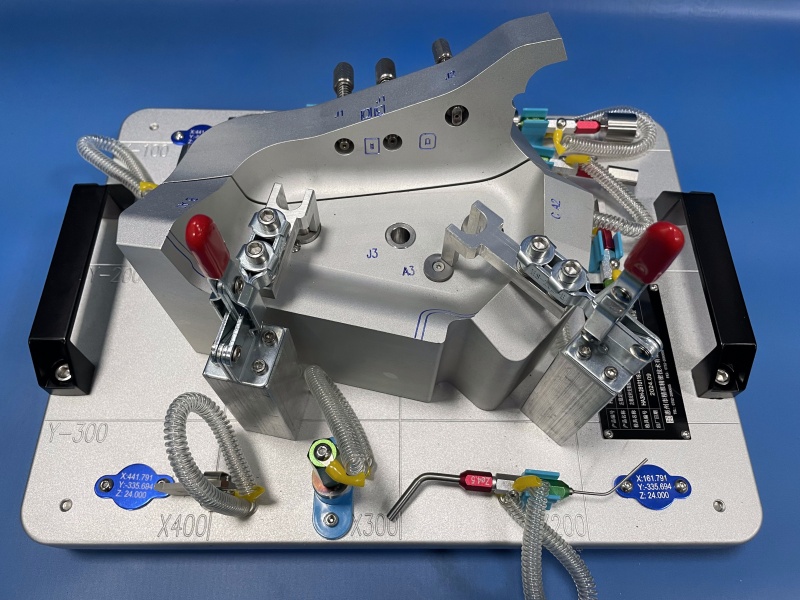

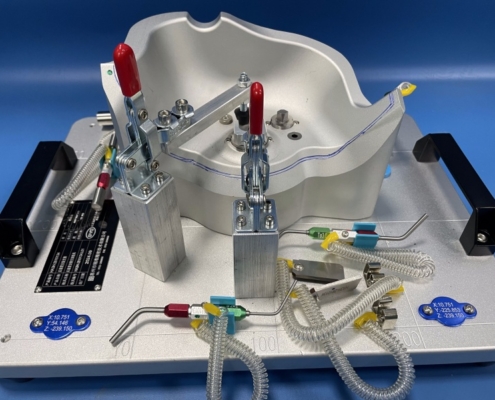

Mold checking tools are precision-engineered devices or fixtures (e.g., custom checking fixtures, inspection fixtures) designed to verify the dimensional accuracy, surface quality, and functional compliance of molds, automotive components, and industrial parts during manufacturing. These tools are tailored to client specifications, ensuring seamless integration with production lines and adherence to strict tolerances

Precision Mold Checking Tools for Automotive and Industrial Applications

Critical Needs Addressed:

✅ Rapid detection of mold defects to reduce scrap rates.

✅ Customized solutions for complex geometries (e.g., car body molds).

✅ Compliance with ISO/AIAG standards for automotive QA.

Key Features:

Our mold checking tools are crafted to address the unique challenges of high-tolerance manufacturing.

- Modular Design Flexibility: Customizable setups adapt to diverse part geometries, minimizing downtime during tool changes.

- Multi-Sensor Integration: Combines laser measurement, vision systems, and tactile probing for comprehensive inspection in one cycle.

- GD&T Compliance: Pre-programmed to validate critical dimensions against ISO/ANSI standards, ensuring regulatory adherence.

- Data-Driven Insights: Generates real-time inspection reports, enabling traceability and process optimization. User-Friendly Interface: Intuitive controls reduce operator training time, boosting productivity from day one.

Technical Specifications:

- Measurement Range: 0.001mm to 500mm (adjustable per application).

- Repeatability: ±0.005mm accuracy under controlled conditions.

- Material Compatibility: Works with steel, aluminum, composites, and plastics.

- Software Integration: Seamless API connectivity with SPC, ERP, or MES systems.

- Environmental Tolerance: Operational in temperatures from 10°C to 40°C.

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Packaging Options:

- To protect your investment during shipping, we offer customizable packaging solutions:

- Samples: Packaged in plastic or wooden boxes for secure delivery.

- Stamping Dies: Secured with wooden plates or customized as per customer requirements to ensure safe transportation.

Car checking fixture company spare parts components

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF