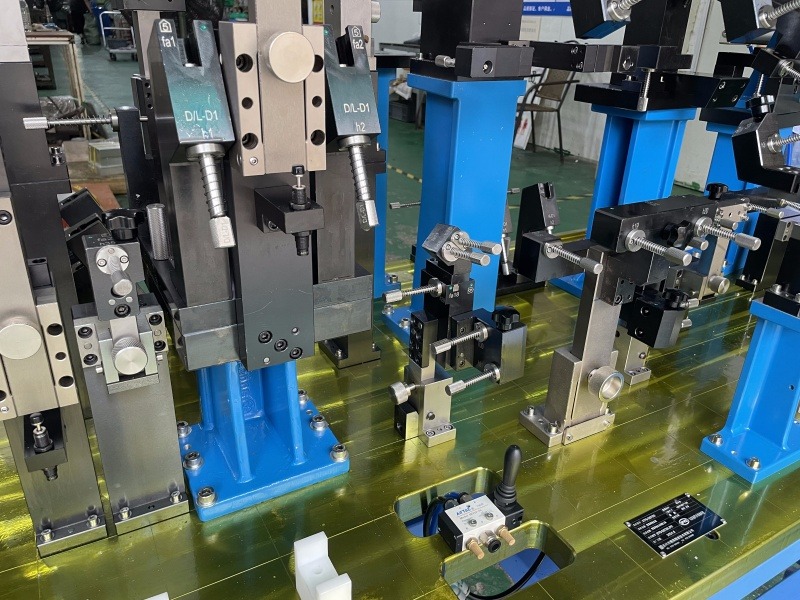

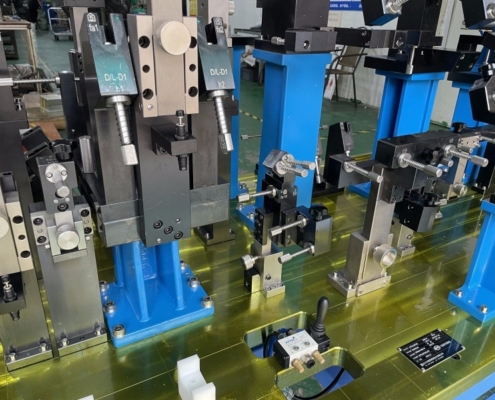

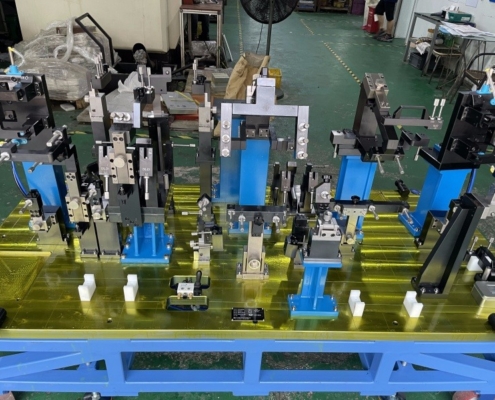

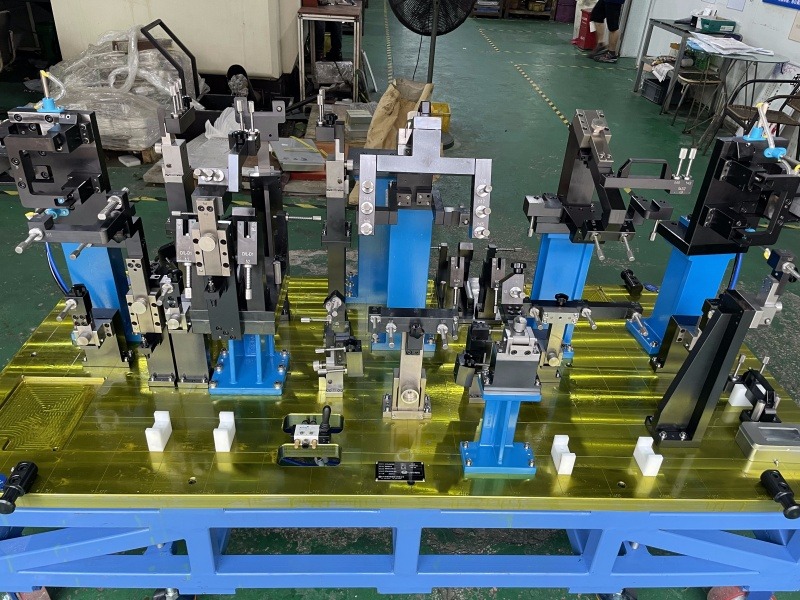

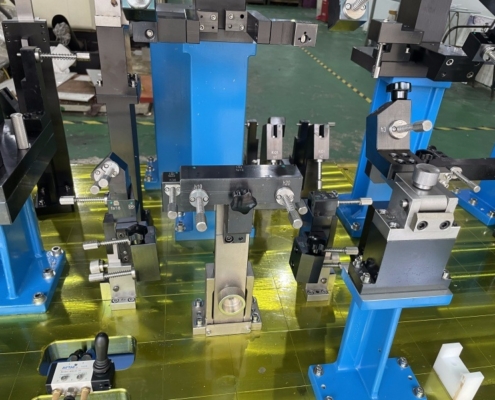

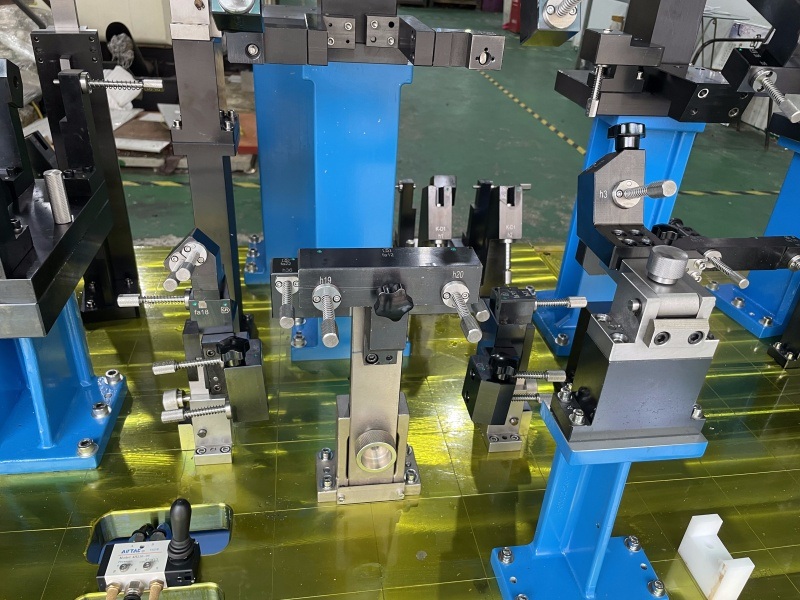

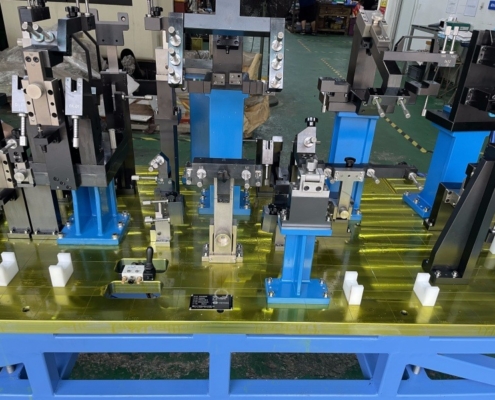

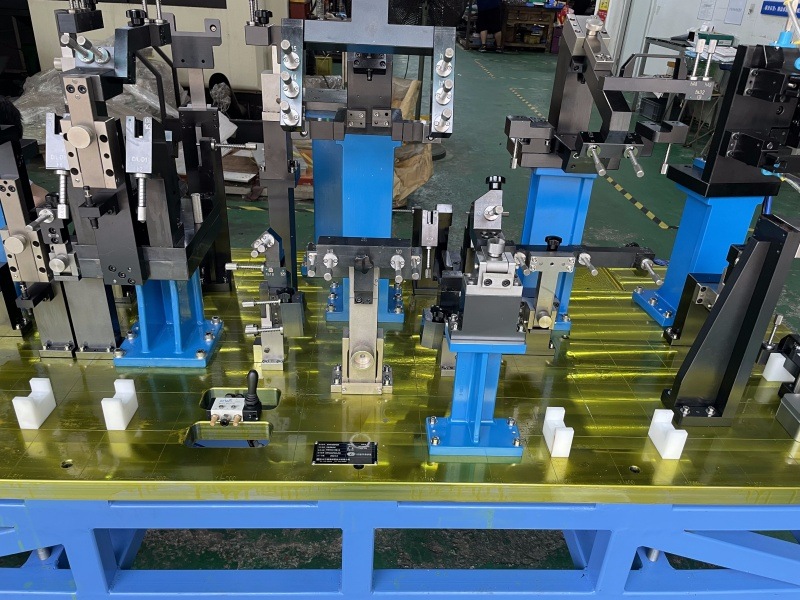

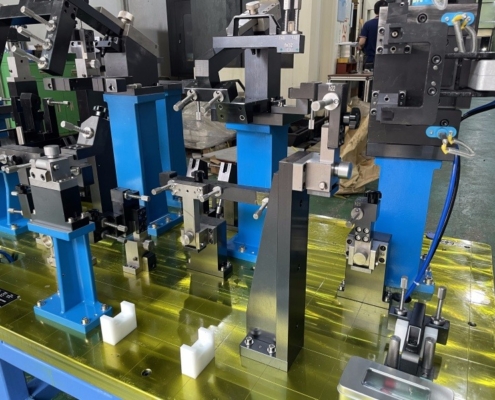

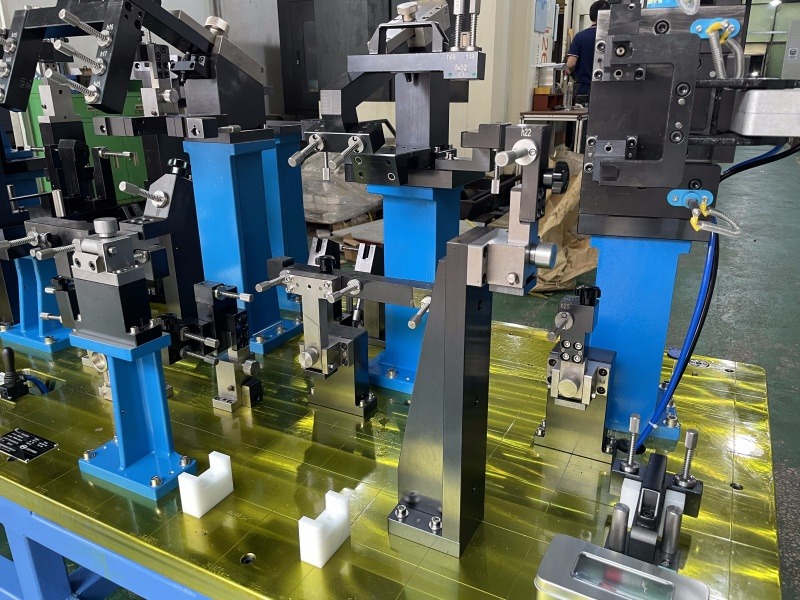

For automotive OEMs and precision manufacturers, ensuring dimensional accuracy in pipe assemblies (exhaust systems, hydraulic lines, fuel conduits) is non-negotiable. Our pipe assembly checking fixtures are engineered to eliminate defects, streamline quality control, and accelerate production timelines. Designed for custom applications in automotive, aerospace, and industrial sectors, these fixtures deliver repeatable precision down to micron-level tolerances.

Check gauge manufacturers company for auto parts

Our Electronic Checking Fixture is a versatile and high-precision tool designed for a variety of checking needs, including:

- Single Metal Parts Checking Fixtures

- Casting Aluminium Parts Checking Fixtures

- Plastic Checking Fixtures

Key Features of Our Inspection Fixtures

✅ Modular Design – Adaptable for different pipe diameters and configurations.

✅ Quick-Clamping Mechanisms – Reduce inspection time without sacrificing accuracy.

✅ 3D Scanning Compatibility – Works with CMM (Coordinate Measuring Machines) for advanced validation.

✅ Error-Proofing (Poka-Yoke) – Prevents misassembly with foolproof locating pins.

✅ Digital Reporting Integration – Export measurement data for traceability.

Technical Specifications at a Glance

- Tolerance Range: ±0.005mm (standard) / ±0.002mm (premium tier)

- Material Options: 6061-T6 aluminum (lightweight), P20 tool steel (heavy-duty)

- Lead Time: 10–45 business days for standard fixtures / 3–4 weeks for complex builds

- Certifications: ISO 9001:2015, ITAR-compliant (on request)

Applications of Our Checking Fixtures

Our pipe assembly checking fixtures are ideal for:

🔹 Automotive Exhaust Systems – Verify welds, bends, and mounting points.

🔹 Fuel & Hydraulic Lines – Ensure leak-proof connections and proper fittings.

🔹 Aerospace Tubing – Validate critical aircraft fluid systems.

🔹 Industrial Pipe Assemblies – Check alignment in HVAC, oil & gas, and machinery.

Why Choose Our Pipe Assembly Checking Fixtures?

✔ High Precision – Manufactured with tight tolerances to detect even minor deviations in pipe assemblies.

✔ Custom Solutions – Tailored to your specific pipe assembly inspection requirements, including complex geometries.

✔ Durability – Built from high-grade materials for long-term use in demanding production environments.

✔ Faster Inspection – Streamline quality control with quick-loading and ergonomic designs.

✔ Industry Compliance – Meets ISO & automotive OEM standards for reliable performance.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF