We manufacture high-accuracy plastic products inspection fixtures for automotive, aerospace, and manufacturing industries. Our custom checking fixtures ensure fast, repeatable quality checks with ±0.1mm tolerance, reducing defects and inspection time by up to 60%.

Key Features Driving Manufacturing Efficiency

- Customizable Designs: Tailored to fit unique product geometries, from intricate medical components to large automotive parts.

- Industrial-Grade Materials: Corrosion-resistant aluminum, high-strength composites, and wear-resistant coatings for longevity.

- Rapid Deployment: Modular systems enable quick changeovers between product variants, minimizing downtime.

- Smart Integration: Compatibility with CMM machines, vision systems, and automated inspection software.

Technical Specifications

- Material Options: Anodized aluminum, engineering-grade polymers, stainless steel inserts.

- Design Software: CAD/CAM integration (SolidWorks, AutoCAD) for seamless digital twin creation.

- Lead Times: 10–14 days for standard designs; 3–4 weeks for fully customized projects.

Applications Across Critical Industries

- Automotive: Dashboard components, interior trims, and under-the-hood plastic parts.

- Consumer Electronics: Housing for appliances, laptops, and wearable devices.

- Medical Devices: Sterilizable fixtures for disposable syringes and diagnostic equipment.

- Packaging: Containers, caps, and blister packs requiring leak-proof validation.

The Customization Process: From Concept to Production

- Consultation: Share your product specs, inspection protocols, and throughput targets.

- 3D Prototyping: Validate fixture functionality with SLA or SLS rapid prototypes.

- CNC Machining: Precision milling and EDM wire cutting for complex geometries.

- Final Testing: Simulate real-world usage with load testing and calibration checks.

Why Choose Our Inspection Fixtures?

1. Superior Material Performance

Made with engineering-grade plastics (PEEK, Delrin, Nylon 12) for:

✓ Corrosion resistance (no rust in humid environments)

✓ 50% longer lifespan vs. aluminum fixtures

✓ Non-marring surfaces to protect delicate parts

2. Customized for Your Exact Needs

3D-scanned & CAD-designed for perfect part fit

Supports GD&T standards for critical dimensions

Options for quick-change inserts (save 35% on retooling)

3. Faster, More Reliable Inspections

Color-coded go/no-go gauges for instant pass/fail checks

Ergonomic handles & under-5kg designs (reduce worker fatigue)

RFID tag slots for digital quality tracking

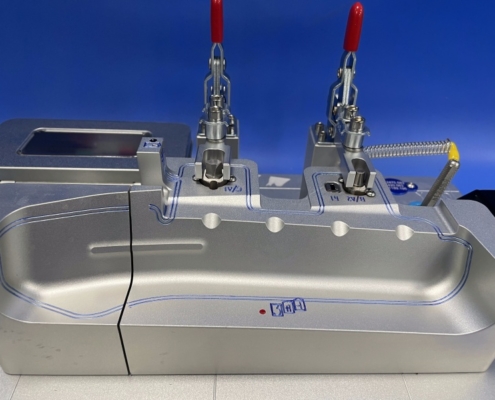

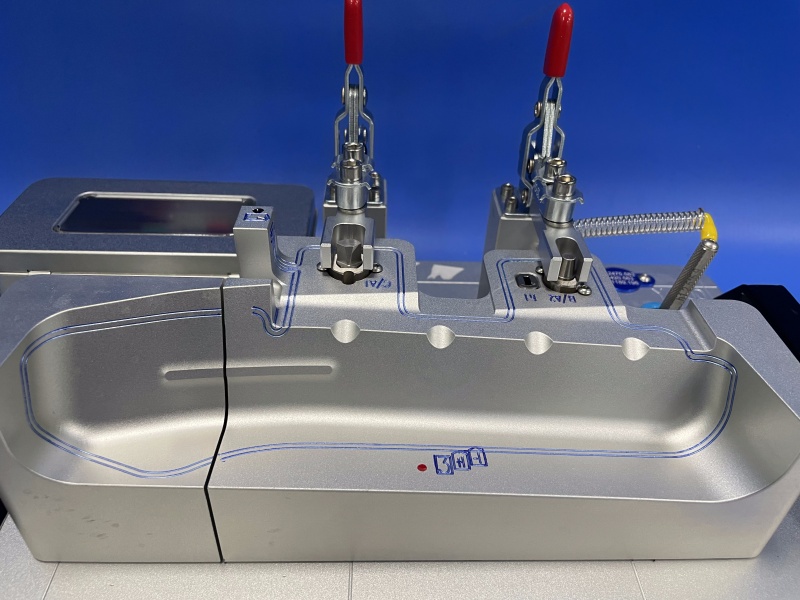

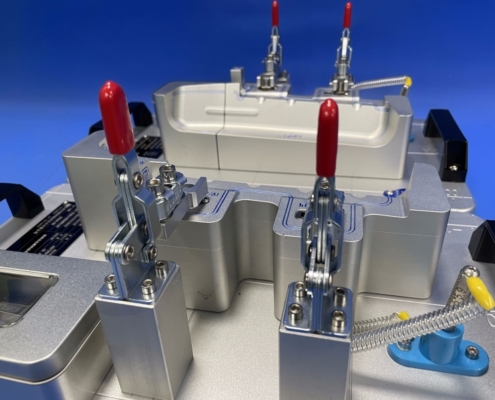

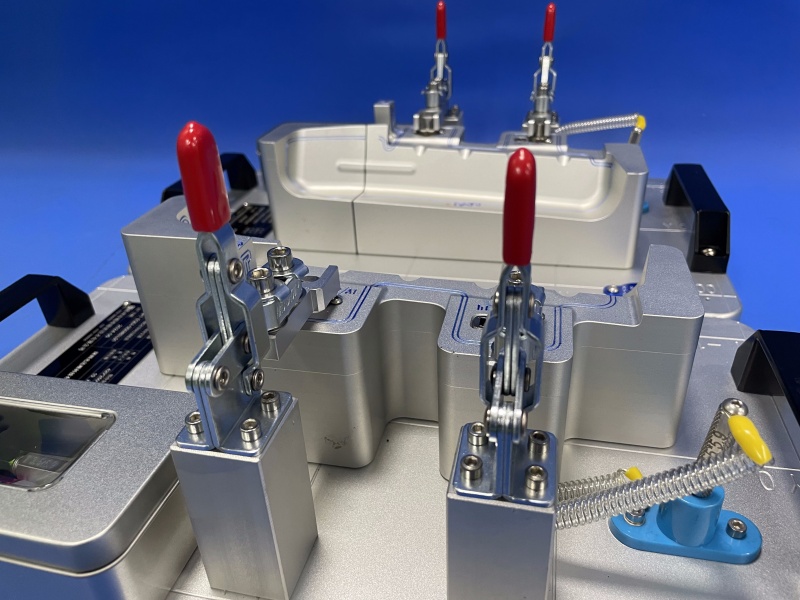

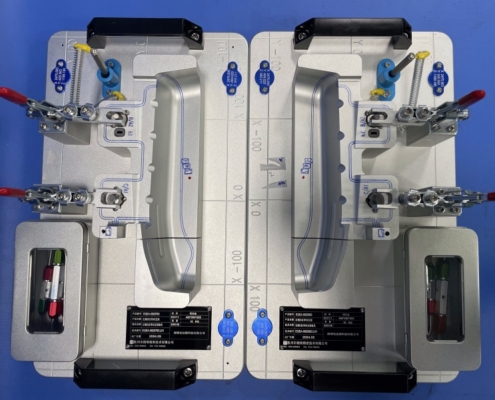

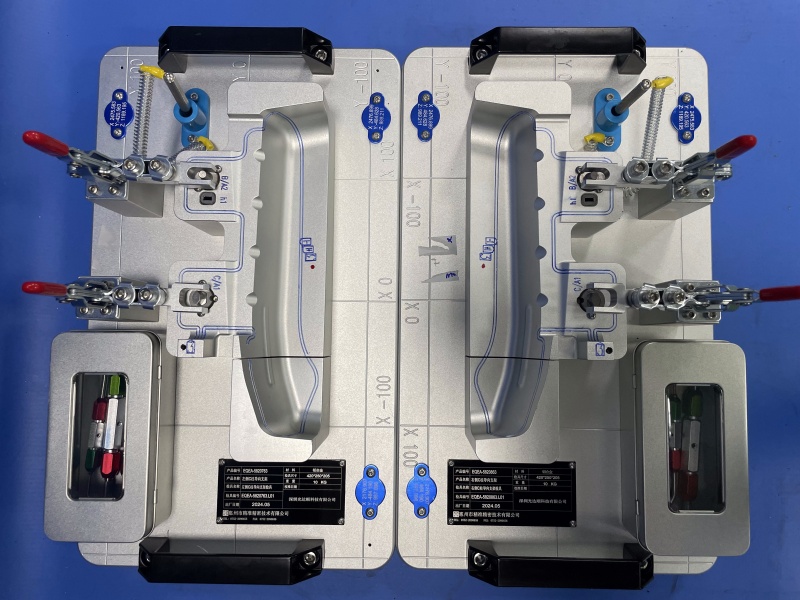

Assembly checking gauge company for A/B/C column

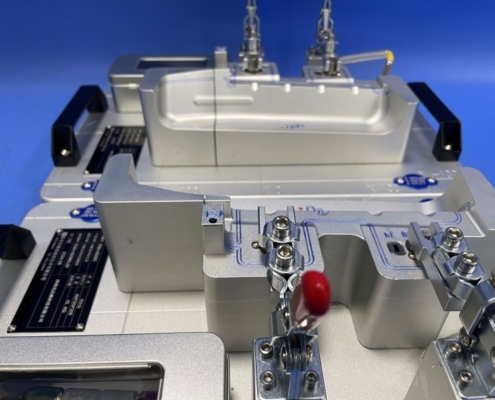

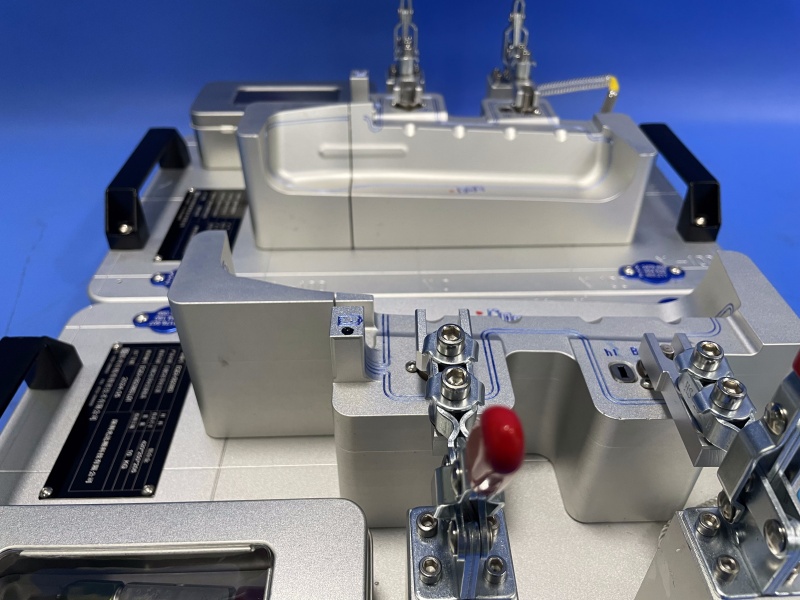

This assembly checking fixture set use cable retractors to control and clamp, and design the SPC ports as part of the flush/feeler rails as opposed to the simulation rail(s).

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF