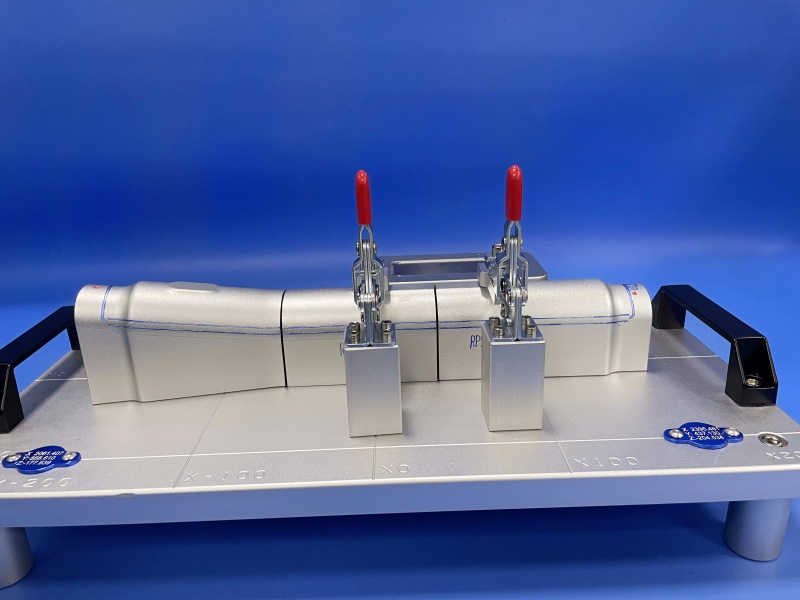

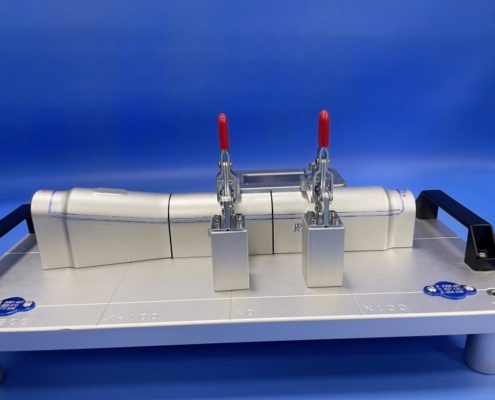

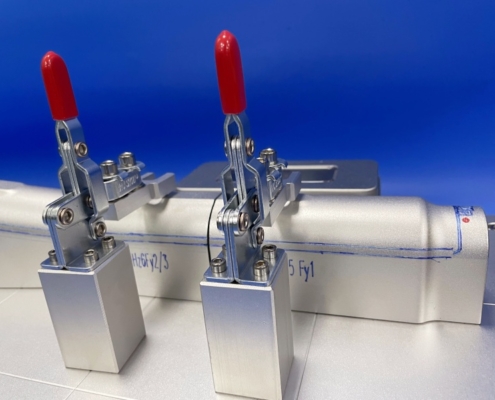

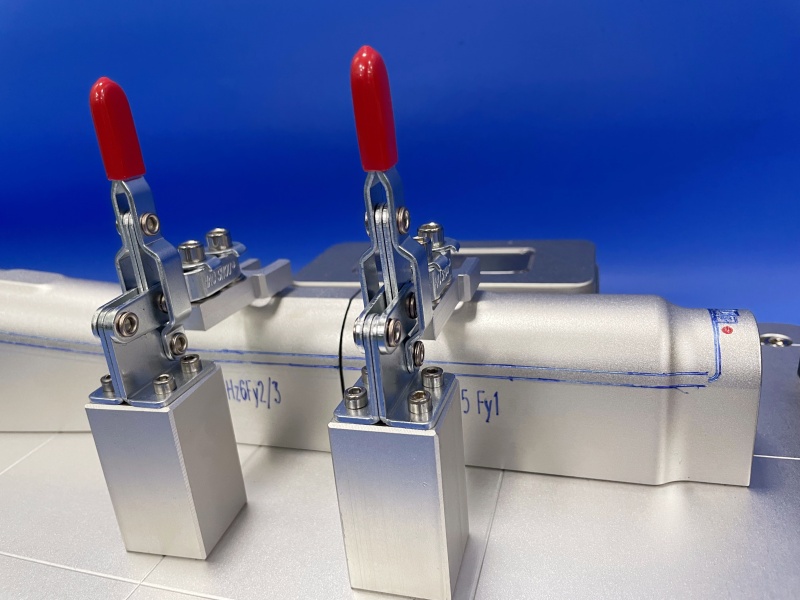

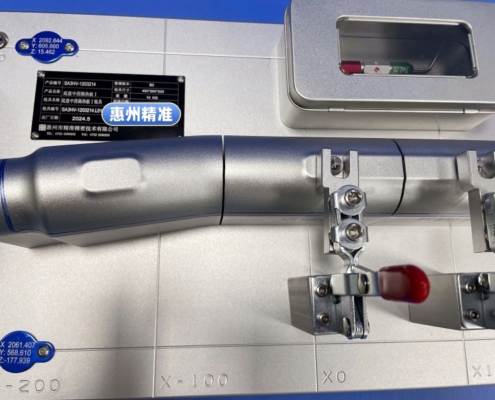

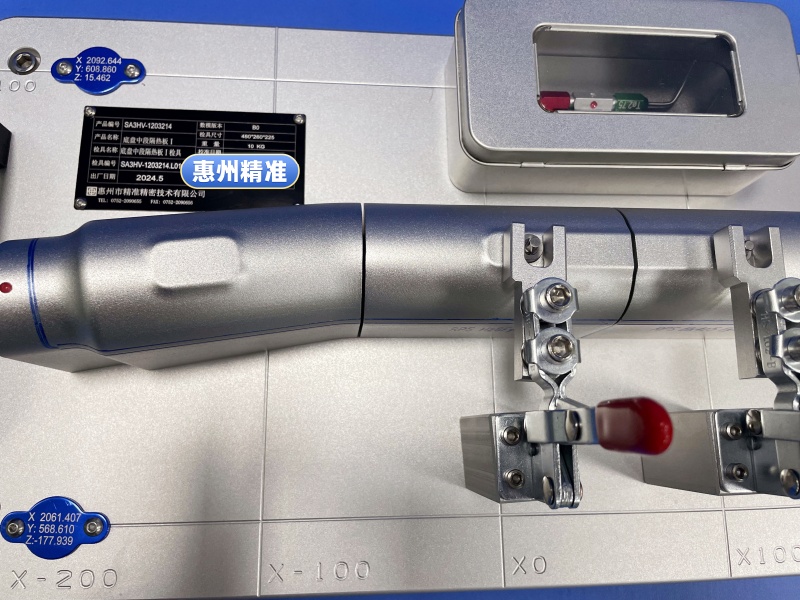

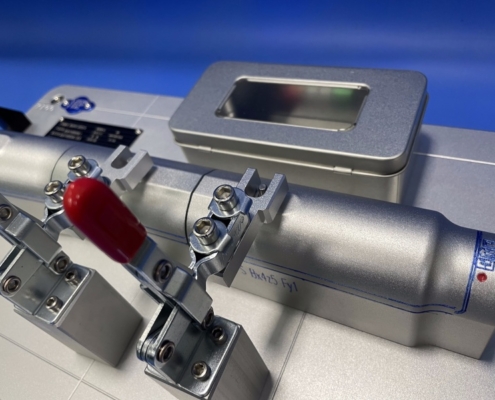

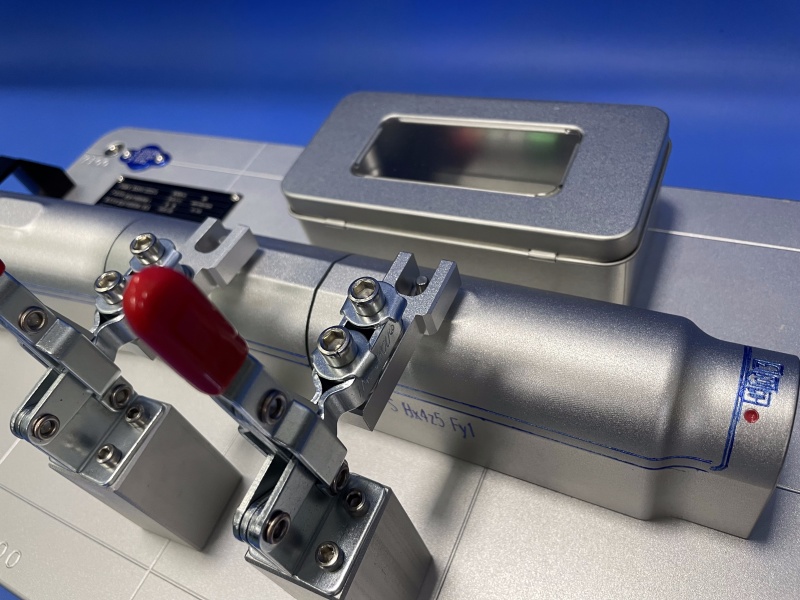

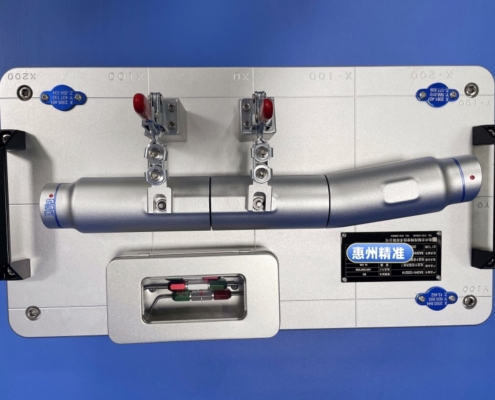

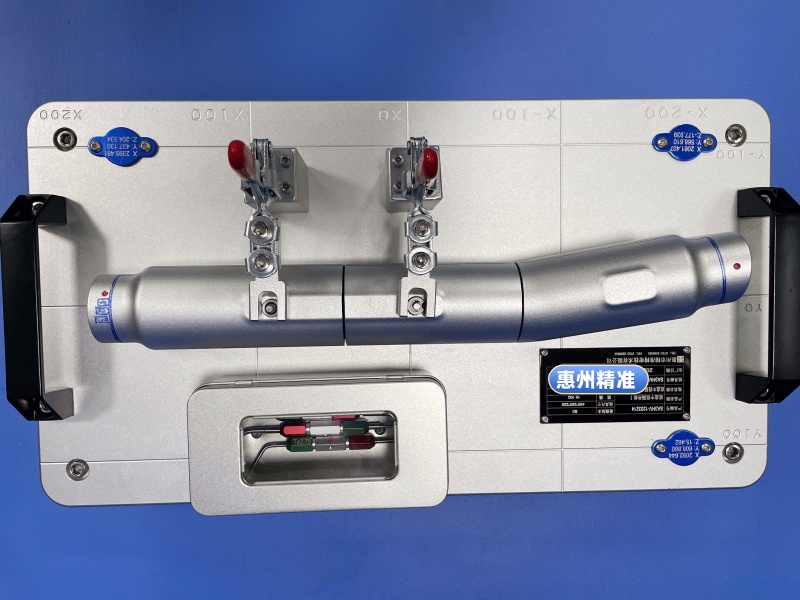

Our precision inspection fixtures are custom measurement solutions designed specifically for manufacturers of high-tolerance components and molds. These industrial-grade verification tools ensure accurate measurement of critical dimensions, positional relationships, and functional performance in production environments.

High-Accuracy Inspection Fixtures Designed for Your Specifications

Our precision inspection fixture can be categorized into three types based on the inspection object:

- Stamping Single-Part Checking Fixture

(For inspecting individual stamped components)

- Subassembly Checking Fixture

(For verifying assemblies composed of multiple parts)

- Modular Integrated Checking Fixture

(Designed for complex systems combining multiple subassemblies)

Key Features:

- Micron-Level Accuracy (±0.015mm repeatability)

- Application-Specific Designs (From prototype to mass production)

- Rapid Changeover (Modular components reduce setup time by 60%)

- Durable Construction (Aircraft-grade aluminum with hardened steel contact points)

Technical Specifications:

- Measurement Range: 5mm to 2m components

- Temperature Stability: ±0.01mm/°C (0-40°C range)

- Materials: Aluminum 6061-T6,

- Stainless Steel options Compliance: ISO 9001, IATF 16949, AS9100 standards

Measurement Capabilities

• Dimensional checks (holes, slots, contours)

• Geometric tolerances (flatness, concentricity)

• Assembly interface validation

• Surface profile verification

Industry Applications

- Automotive: Transmission cases, EV battery components

- Aerospace: Turbine blades, structural brackets

- Medical: Implant molds, surgical instruments

- Electronics: Connector housings, heat sinks

Auto Checking Fixture Standard Part Measurement concept

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF