Custom Fixture Types We Deliver

Measuring Holder (Holding Fixture)

Specifically designed for three-coordinate measurement, through the fixed parts and simulate the body coordinate system, accurate extraction of characteristic data (such as holes, profiles)

Example: Wheel hub fixtures, through high-precision modular design (base plate aluminum, reference steel parts) to achieve dimensional inspection (accuracy of ± 0.05mm)

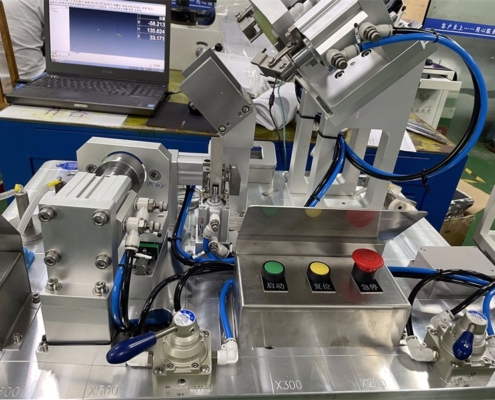

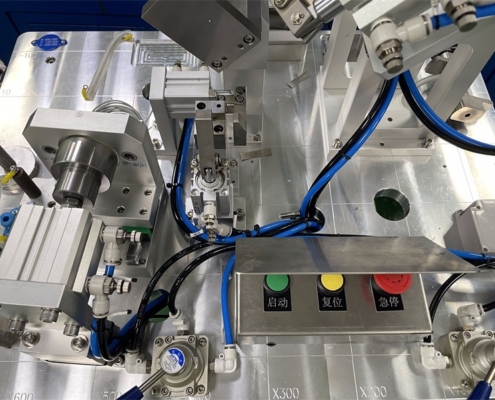

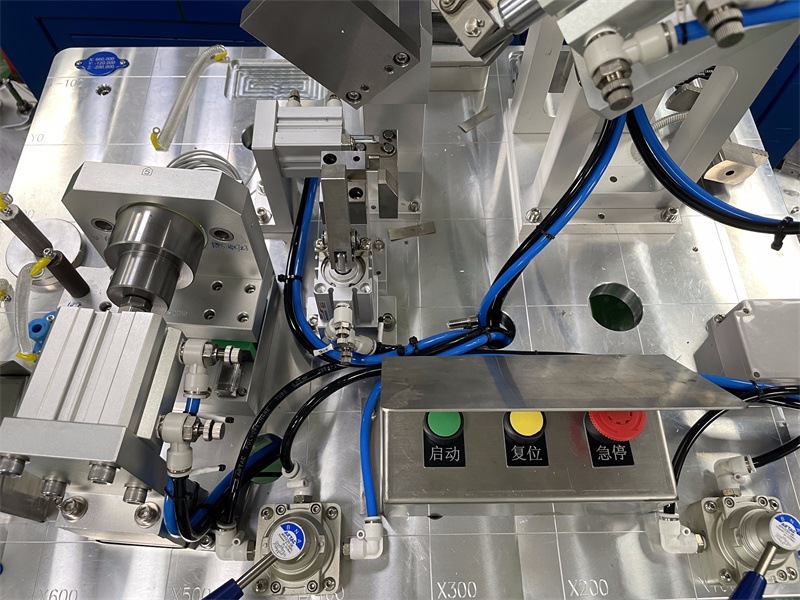

Functional Gauge

Used to verify the fit of multiple components, such as door assembly gages, detecting parameters such as clearance and surface difference.

Example: automobile main driver lower guard assembly gage, integrated fixing mechanism (tray, clamping components) and detection module (laser, aperture detection box), to ensure the stability of the test

Functional Master Model Gauge

Simulates the structure of the whole vehicle or sub-assembly, verifies the functionality of the components (e.g. opening and closing parts movement trajectory, sealing).

According to the test object classification Single-piece gage For a single part of the key dimensions of the inspection, such as the engine cylinder inspection tool Comprehensive assembly gage Detecting the overall fitness of the assembly of multiple parts, such as the body welded assembly gage Specialized Gauges Customized tools for specific scenarios, e.g. wheel fixtures that support quick mold changes to accommodate different wheel types.

Download PDF

Download PDF