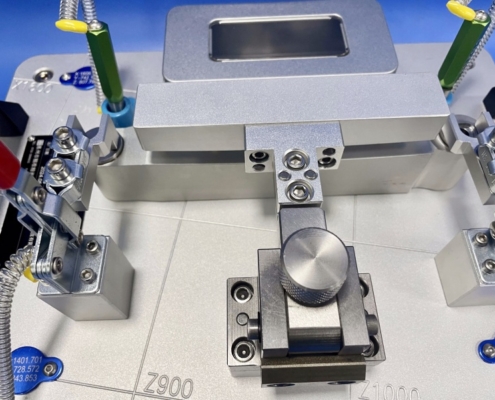

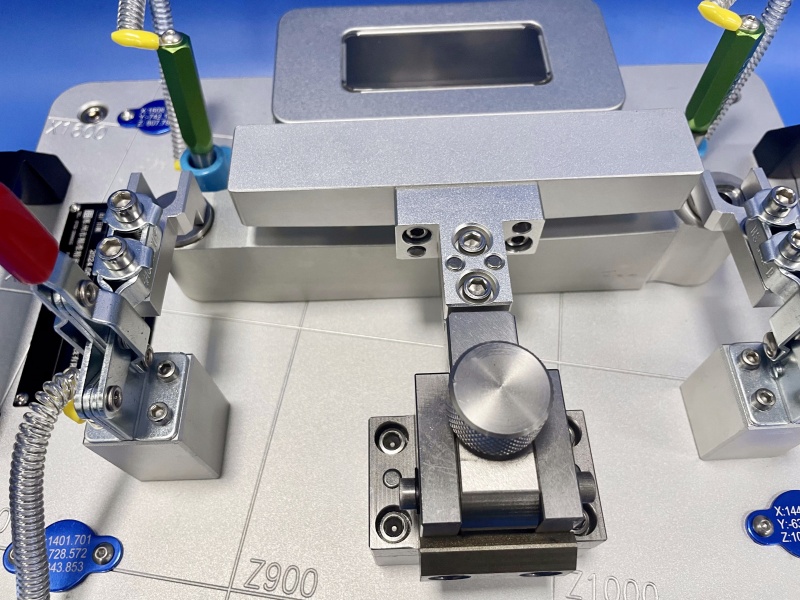

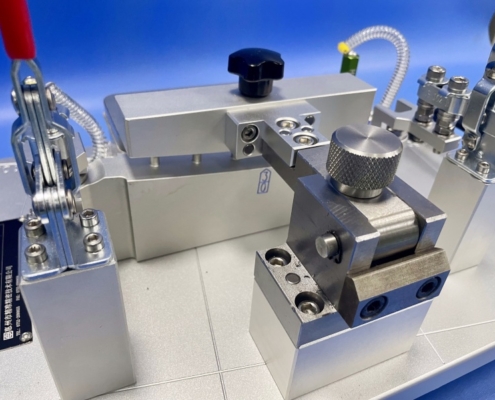

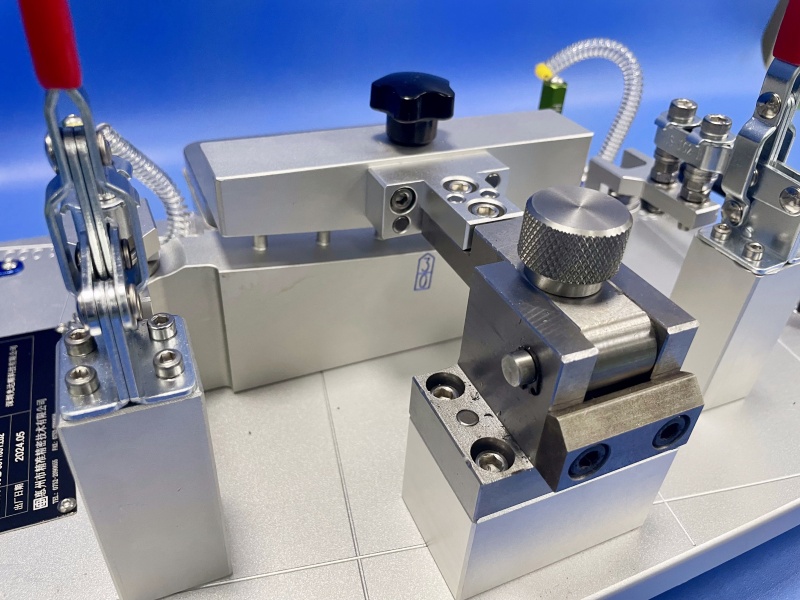

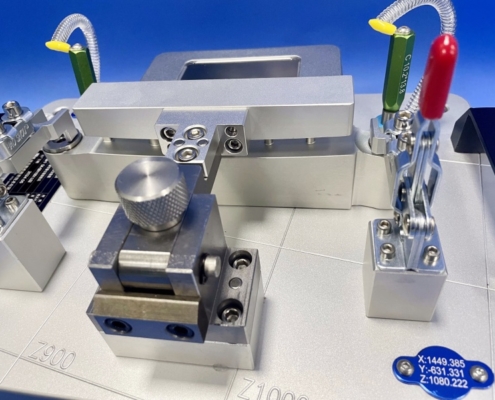

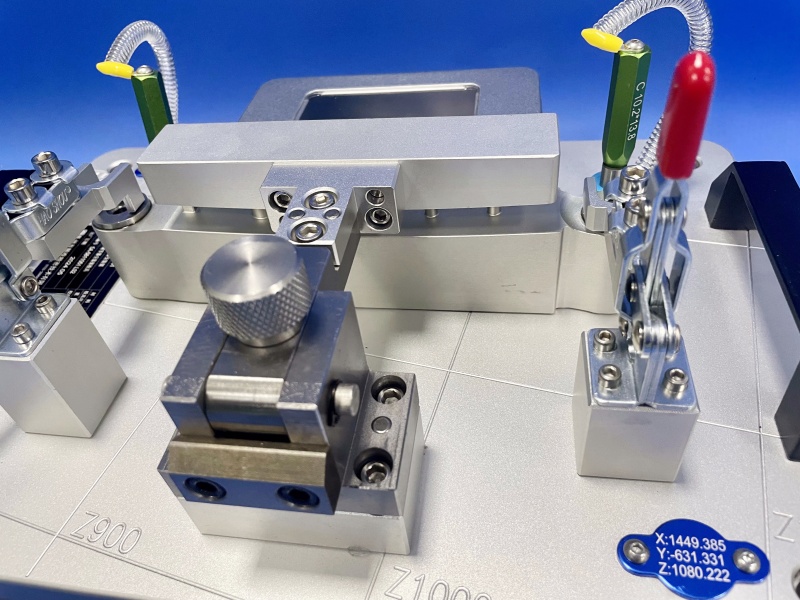

Testing jigs inspection fixtures” are precision measurement tools used in automotive and mold manufacturing to verify part dimensions against CAD designs. These custom-built fixtures ensure quality control by accurately locating and checking components during production.

Testing inspection fixture Solutions for Mold & Assembly Lines

✅ Ultra-Precise Positioning

Hardened stainless steel locators with 5μm repeatability

Integrated datum system compatible with CMM verification

✅ Industry-Specific Customization

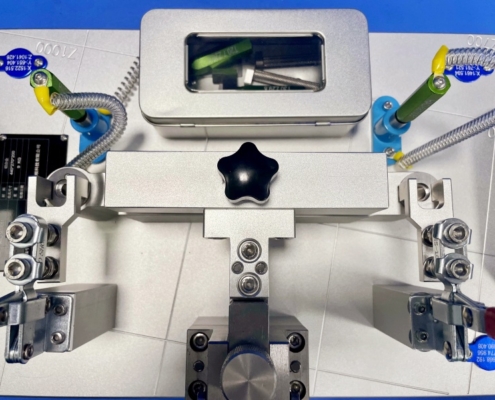

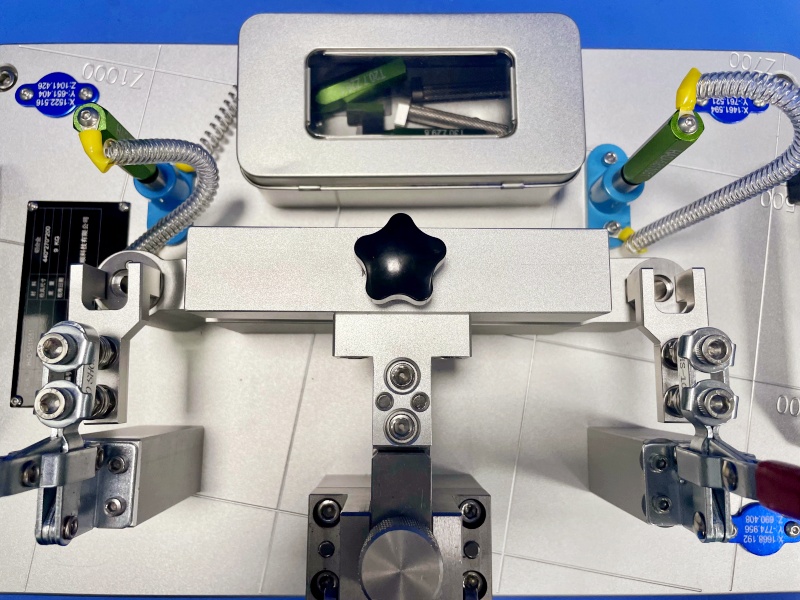

Modular designs for mold core/cavity inspection

Quick-change adapters for multi-model car assemblies

✅ Durability Optimized

55-60 HRC steel base plates withstand 100,000+ cycles

IP54-rated components for shop floor environments

Key Features:

✅ Modular Design: Customizable to adapt to diverse component geometries and inspection requirements.

✅ High Precision: Ensures ±0.005mm accuracy for critical measurements.

✅ Durable Construction: Aerospace-grade aluminum or stainless steel frame for long-term stability.

✅ Intuitive Interface: Color-coded indicators and ergonomic clamps simplify operator use.

✅ Quick-Change System: Swap tooling inserts in under 5 minutes for multi-part inspection.

✅ Data Integration: Optional digital readouts or IoT connectivity for real-time analysis.

Technical Specifications:

- Measurement Range: 0-500mm (customizable)

- Repeatability: ≤0.002mm

- Material Compatibility: Aluminum, steel, composites, plastics

- Weight Capacity: Up to 20kg (fixture-dependent)

- Operational Temp: -20°C to 80°C

Quality Assurance:

Our fixtures are subjected to stringent quality checks using advanced Coordinate Measuring Machines (CMM) to confirm their accuracy and performance. This rigorous process ensures that every fixture meets the highest standards of quality and reliability.

Applications

- Mold Component Validation: Checks critical dimensions of inserts, cores, and cavities.

- Functional Testing: Verifies assembly clearance, alignment, and motion mechanics.

- QC Audit Support: Standardizes inspection protocols across production batches.

- Prototype Evaluation: Accelerates design iteration with rapid feedback loops.

- Automated Lines: Integrates with robotic arms or CMM machines for end-to-end quality control.

| P&A Accurate Technology Co., ltd. | |

| Second Floor No. 1 Fengyuan Road, Chenjiang Street, Zhongkai High-tech Zone, Huizhou | |

| 0752-2090655 | |

| 13413175198 | |

| sales@jztester.com | |

| www.jztester.com |

Download PDF

Download PDF