Why said that checking fixture is the soul of modern automobile manufacturing

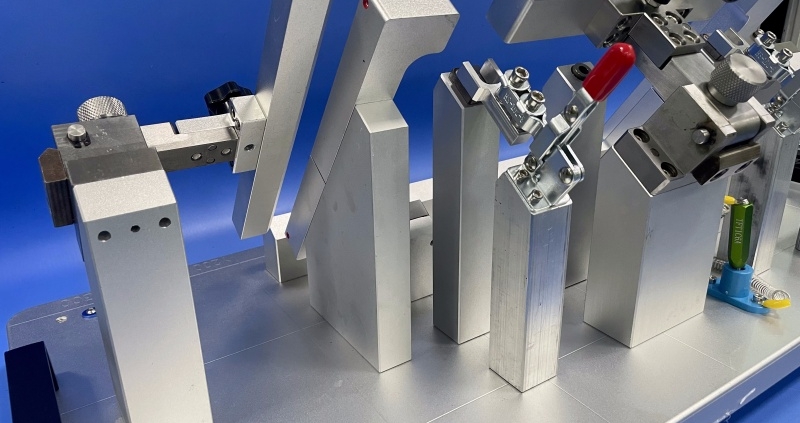

When we talk about car manufacturing, we usually focus on aspects such as design, materials, process, and quality control. But there is one key factor that is often overlooked, and that is the checking fixture. It’s plays a vital role in the automobile manufacturing, which directly affects the quality and reliability of the automobile. The influence of checking fixture on automobile manufacturing is mainly reflected in the following aspects:

Automobile manufacturing:

The checking fixture is an important tool to ensure the quality of automobile manufacturing. By using the checking fixture to test the parts in the manufacturing process, it can ensure that they meet the design requirements and reduce errors and defects. This helps to improve manufacturing efficiency, reduce scrap rates and thus reduce production costs.

Automobile quality:

The accuracy and reliability of the inspection tool directly affect the quality of the automobile. If there are errors or defects in the tester itself, then the detected parts will also be affected, which may lead to a decrease in the overall performance of the car. Therefore, it is very important to choose high quality checking fixture.

Auto safety:

Checking fixture is also vital to ensure the safety of the car. The size, shape and position of key components such as braking systems, steering systems and engine components have an important impact on vehicle safety. If the size, shape or location of these parts does not meet the requirements, it can lead to serious safety issues. Potential safety hazards can be reduced by rigorously testing these critical components with the use of checking fixture.